Floor heating heating pipe with low linear expansion coefficient and preparation method thereof

A technology of linear expansion coefficient and heating pipe, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of no research on floor heating heating pipes, and the requirements for cross-linking degree and linear expansion coefficient of floor heating heating pipes are not considered. , to reduce the high temperature precipitates, improve the grafting reaction efficiency, and improve the plasticity index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

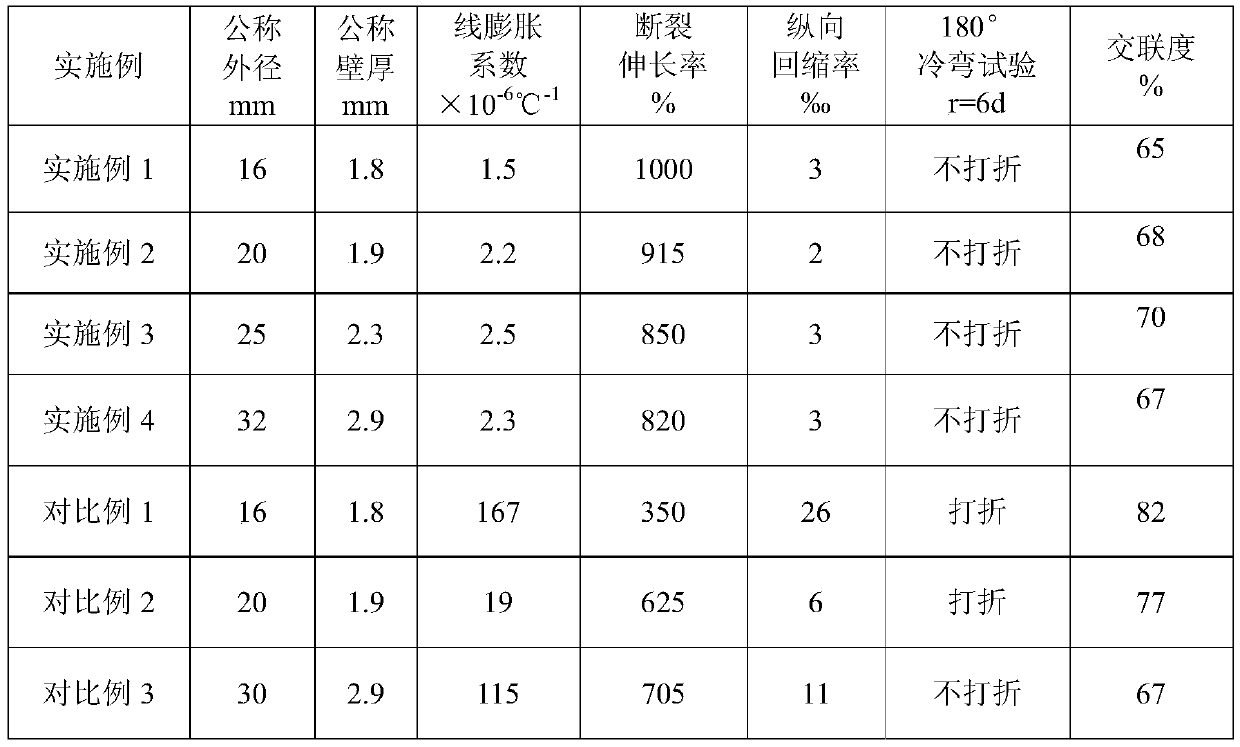

Examples

Embodiment 1

[0028] Floor heating heating pipe with a nominal outer diameter of 16mm and a nominal wall thickness of 1.8mm with a low coefficient of linear expansion.

[0029] The formula of the heating tube: HDPE: 85kg; LDPE: 7.5kg; PPR: 7.5kg; vinyltrimethoxysilane: 0.40kg; dicumyl peroxide: 0.035kg; dibutyltin dilaurate: 0.50kg; Dosage 1010: 0.040kg.

[0030] The key steps and key parameters for preparing the above heating tube are as follows:

[0031] (1) Matrix resin drying, drying temperature: 95°C, drying time: 1.9h / t.

[0032] (2) Four-stage single-screw extrusion molding, screw diameter: 80mm, screw length-to-diameter ratio: 30, the temperature of the feeding section is 185°C, the temperature of the melting section is 208°C, the temperature of the homogenization section is 217°C, and the temperature of the reaction section is 230°C, the head temperature is 230°C.

[0033] (3) Argon vacuum calibration, the vacuum degree is 1.4bar.

[0034] (4) Compressed air purging, the compre...

Embodiment 2

[0038] Floor heating heating pipe with a nominal outer diameter of 20mm and a nominal wall thickness of 1.9mm with a low coefficient of linear expansion.

[0039] The formula of the heating tube is: HDPE: 90kg; LDPE: 5.0kg; PPR: 5.0kg; vinyltrimethoxysilane: 0.20kg; dicumyl peroxide: 0.040kg; dibutyltin dilaurate: 0.60kg; Oxygen agent 1010: 0.030kg.

[0040] The key steps and key parameters for preparing the above heating tube are as follows:

[0041] (1) Matrix resin drying, drying temperature: 92°C, drying time: 1.5h / t.

[0042] (2) Four-stage single-screw extrusion molding, screw diameter: 85m, screw length-to-diameter ratio: 35, the temperature of the feeding section is 180°C, the temperature of the melting section is 210°C, the temperature of the homogenization section is 210°C, and the temperature of the reaction section is 225°C, the head temperature is 225°C.

[0043] (3) Argon vacuum calibration, the vacuum degree is 1.2bar.

[0044] (4) Compressed air purging, th...

Embodiment 3

[0048] Floor heating heating pipe with a nominal outer diameter of 25mm and a nominal wall thickness of 2.3mm with a low coefficient of linear expansion.

[0049] The formula weight ratio of the heating tube is composed of: HDPE: 87.5kg; LDPE: 5.5kg; PPR: 7.0kg; vinyltrimethoxysilane: 0.37kg; dicumyl peroxide: 0.032kg; dibutyltin dilaurate: 0.55kg; antioxidant 1010: 0.035kg.

[0050] The key steps and key parameters for preparing the above heating tube are as follows:

[0051] (1) Matrix resin drying, drying temperature: 94°C, drying time: 1.8h / t.

[0052] (2) Four-stage single-screw extrusion molding, screw diameter: 90mm, screw length-to-diameter ratio: 35, the temperature of the feeding section is 182°C, the temperature of the melting section is 205°C, the temperature of the homogenization section is 212°C, and the temperature of the reaction section is 228°C, head temperature is 230°C.

[0053] (3) Argon vacuum calibration, the vacuum degree is 1.3bar.

[0054] (4) Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| cross-linking degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com