Method for bipolarly and electrochemically synthesizing Janus microsphere of petal-shaped metal organic framework object ZIF-8 by virtue of ionic liquid

A metal organic framework, ZIF-8 technology, applied in the direction of electrolytic organic production, electrolytic process, electrolytic components, etc., to achieve the effect of low cost and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

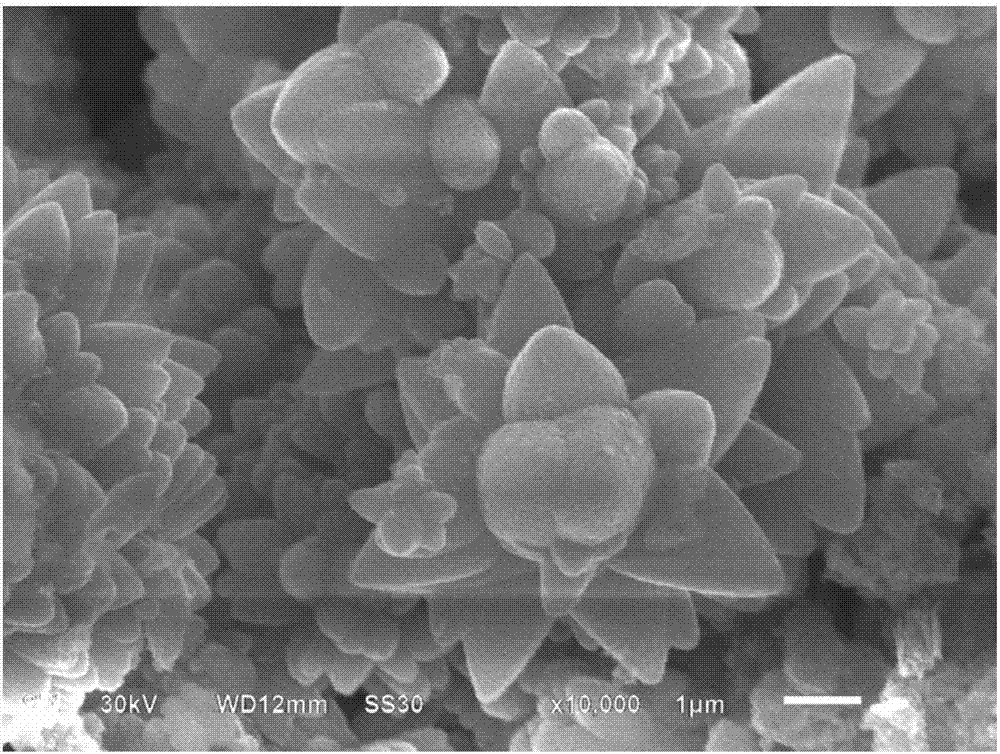

Embodiment 1

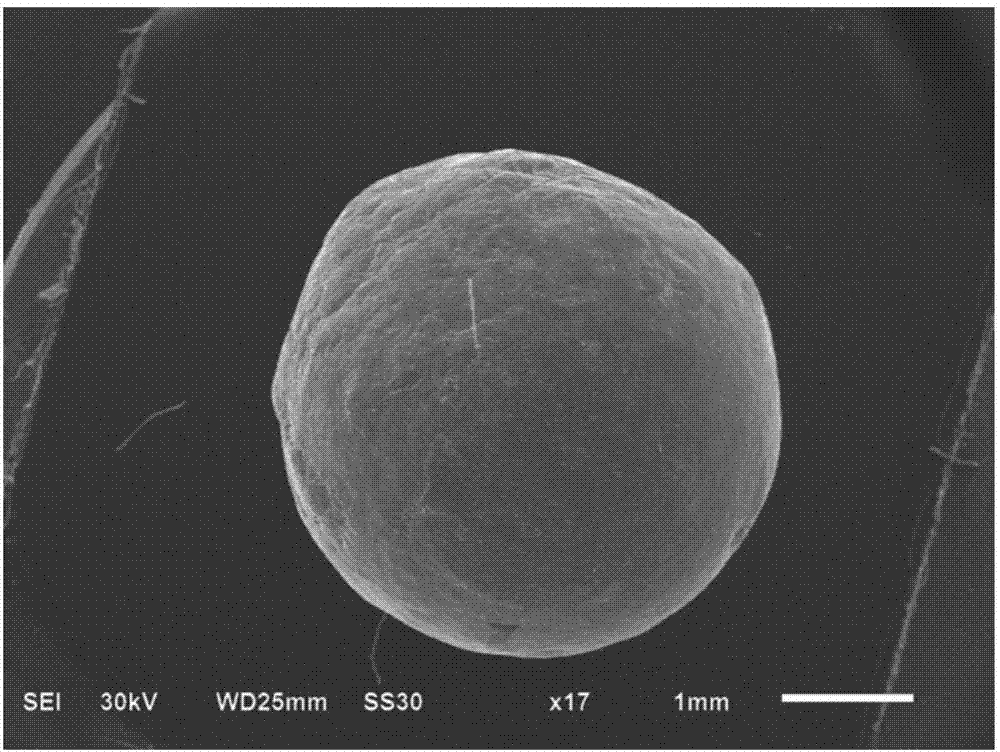

[0022] (1) Construct a device for a bipolar electrochemical synthesis system: the device for a bipolar electrochemical synthesis system consists of a DC drive power supply, a graphite sheet drive electrode, a bipolar electrode zinc microsphere, a perfluorosulfonic acid ion diaphragm and Composed of polytetrafluoroethylene square grooves. The anode and cathode of the drive electrode are connected to the positive and negative poles of the DC drive power supply with wires respectively. The anode and cathode of the graphite sheet drive electrode are placed at the two ends of the polytetrafluoroethylene square groove at the same time, and the graphite sheet drive electrode anode and graphite sheet drive electrode The distance between the cathodes is 2.5cm; the bipolar electrode zinc microspheres are placed between the anode and cathode of the driving electrode, and the anode and cathode of the graphite sheet driving electrode are connected to the bipolar electrode zinc with a perflu...

Embodiment 2

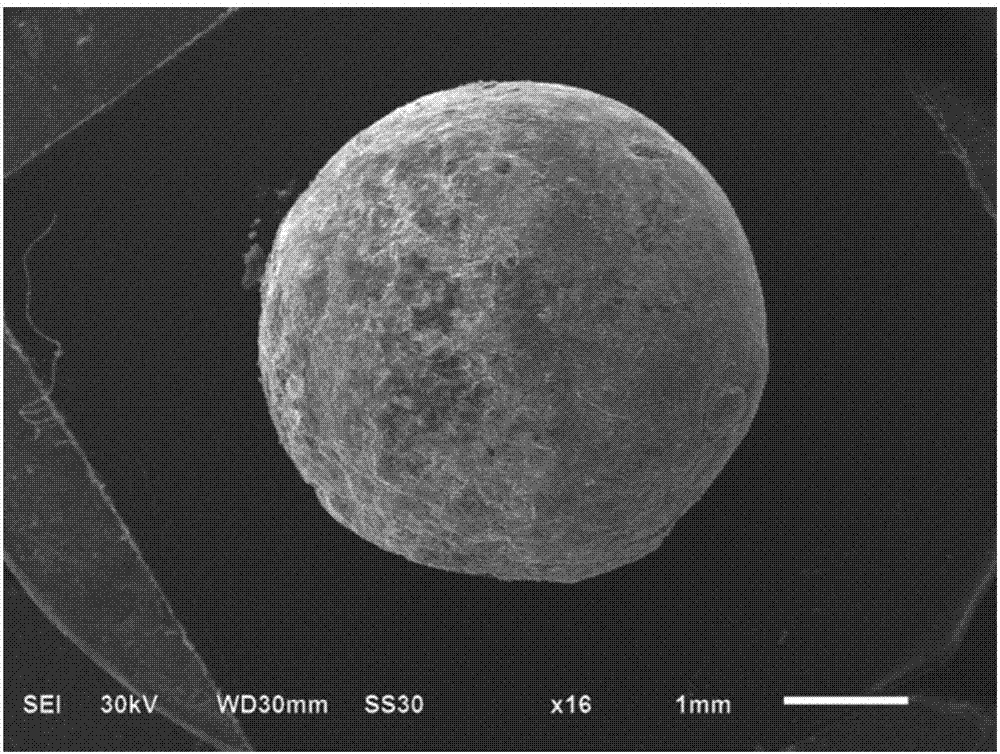

[0032] (1) Construct a device for a bipolar electrochemical synthesis system: the device for a bipolar electrochemical synthesis system consists of a DC drive power supply, a graphite sheet drive electrode, a bipolar electrode zinc microsphere, a perfluorosulfonic acid ion diaphragm and Composed of polytetrafluoroethylene square grooves. The anode and cathode of the drive electrode are connected to the positive and negative poles of the DC drive power supply with wires respectively. The anode and cathode of the graphite sheet drive electrode are placed at the two ends of the polytetrafluoroethylene square groove at the same time, and the graphite sheet drive electrode anode and graphite sheet drive electrode The distance between the cathodes is 2.5cm; the bipolar electrode zinc microspheres are placed between the anode and cathode of the driving electrode, and the anode and cathode of the graphite sheet driving electrode are connected to the bipolar electrode zinc with a perflu...

Embodiment 3

[0038] (1) Construct a device for a bipolar electrochemical synthesis system: the device for a bipolar electrochemical synthesis system consists of a DC drive power supply, a graphite sheet drive electrode, a bipolar electrode zinc microsphere, a perfluorosulfonic acid ion diaphragm and Composed of polytetrafluoroethylene square grooves. The anode and cathode of the drive electrode are connected to the positive and negative poles of the DC drive power supply with wires respectively. The anode and cathode of the graphite sheet drive electrode are placed at the two ends of the polytetrafluoroethylene square groove at the same time, and the graphite sheet drive electrode anode and graphite sheet drive electrode The distance between the cathodes is 2.5cm; the bipolar electrode zinc microspheres are placed between the anode and cathode of the driving electrode, and the anode and cathode of the graphite sheet driving electrode are connected to the bipolar electrode zinc with a perflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com