Novel high pressure resistant, anti-corrosion and high temperature resistant membrane shell and preparation method thereof

A high-temperature-resistant membrane and corrosion-resistant technology, applied in the field of membrane shells and their preparation, can solve the problems of low space utilization, increased cost of seawater desalination, high equipment investment costs, etc., to achieve a wide range of manufacturing sizes, improve space utilization, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

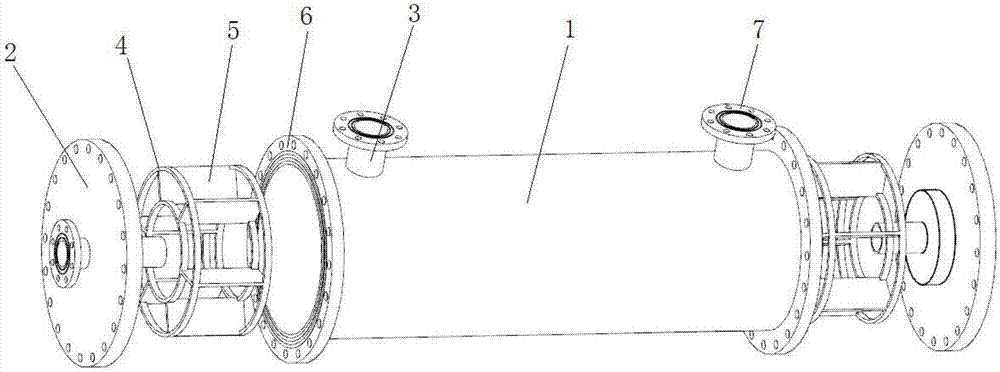

[0026] Such as figure 1 , 2 As shown, a new type of high-pressure, corrosion-resistant, and high-temperature-resistant membrane shell includes a housing 1, the housing 1 is a hollow cylinder, the two ends of the housing 1 are connected with end caps 2, and the axial ends of the outer surface of the housing 1 are A branch pipe 3 is provided respectively, and a membrane element support 4 is provided in the corresponding position of each branch pipe 3 inside the housing 1, and each membrane element support 4 includes two opposite ring groups, and the two ring groups pass through the rib plate 5. Fixed connection, each ring group includes at least two concentric rings.

[0027] Both ends of the housing 1 are provided with end flanges 6 and are flange-connected with the end cover 2 .

[0028] The end of the branch pipe 3 is provided with a connecting flange 7, which is convenient for connecting with external equipment.

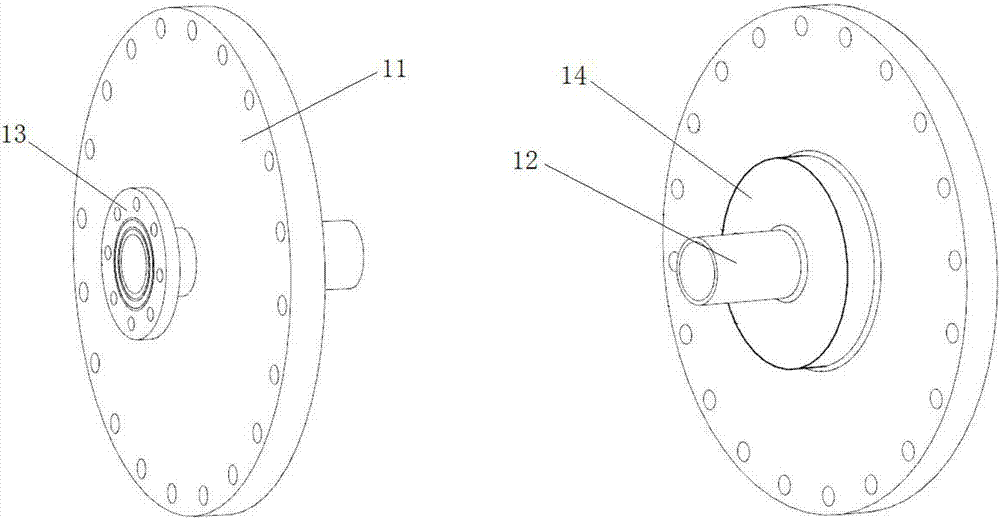

[0029] The end cover 2 includes a solid flange disc 11, th...

Embodiment 2

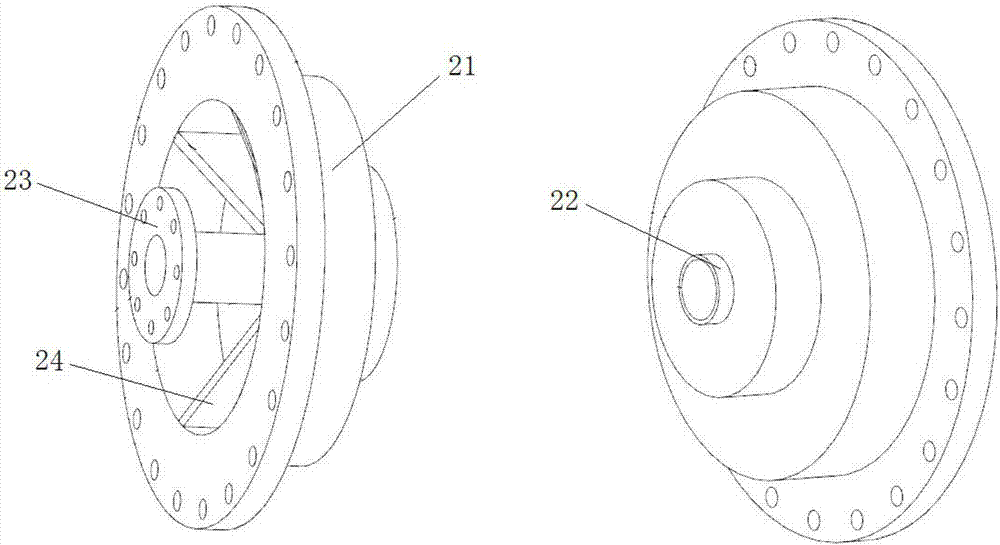

[0031] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the end cover 2 includes a stepped flange disc 21 sunken inward, and a second central tube 22 is arranged at the center of the stepped flange disc 21, and the second center The outer end of the tube 22 is provided with a second flange 23 , and several reinforcing ribs 24 are arranged between the outer root of the second central tube 22 and the concave surface of the stepped flange disc. The above-mentioned end cover saves material and reduces manufacturing cost.

[0032] The shell is directly made of materials that are resistant to high pressure, corrosion, and high temperature, such as stainless steel, titanium alloy, etc.

[0033] The inner body of the shell and the outer coating are compounded. The inner body is made of high-pressure resistant materials, such as carbon steel, and the outer coating is made of corrosion-resistant and high-temperature resistant materials, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com