A 3D printing forming method of high-voltage electric conversion polymer material crystal form

A polymer material and 3D printing technology, which is applied in the direction of liquid material additive processing, additive processing, and processed material handling, etc., can solve problems such as the inability to realize polycrystalline polymer printing crystal form control, and achieve shape controllable, The effect of safe system operation and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

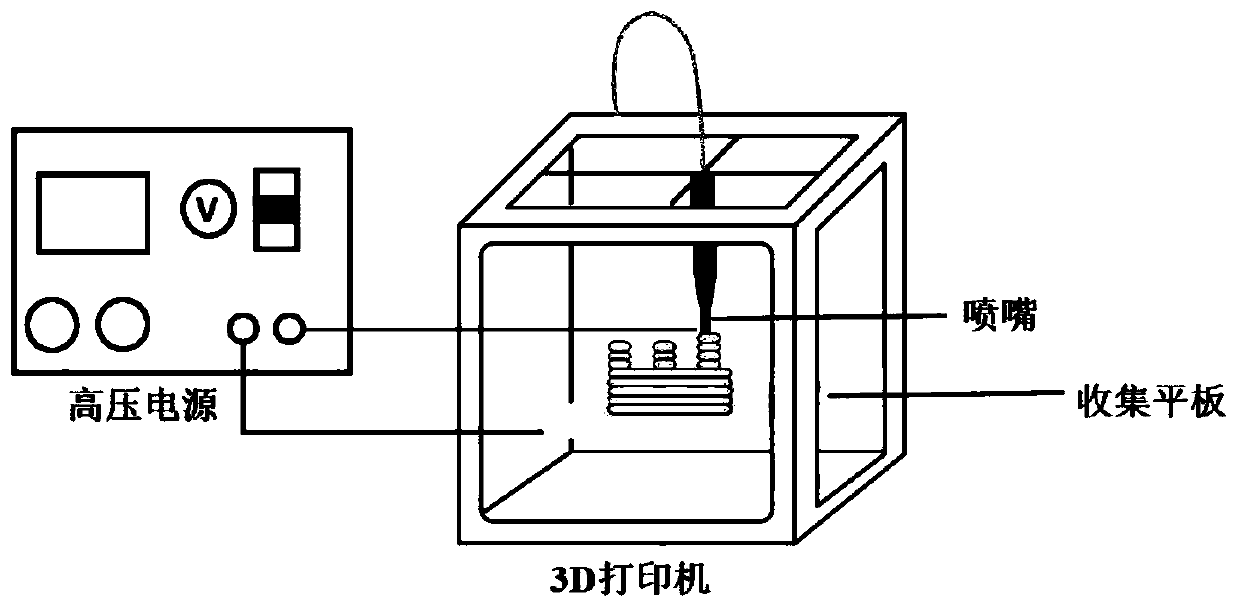

[0032] 1) Feeding: Feed pyroelectric materials such as polyvinylidene fluoride (PVDF) wire into the nozzle of the 3D printer and clamp it tightly. Set the temperature of the nozzle to 210°C, the outer diameter of the nozzle to 0.3mm, and the distance between the nozzle and the collection platform. The distance is 100cm;

[0033] 2) Connect to the high-voltage power supply: Connect the two poles of the high-voltage power supply to the nozzle of the 3D printer and the collection platform respectively, set the high voltage value, and the voltage value is 100KV;

[0034] 3) Set process parameters: feed speed is generally 20mm / s; nozzle temperature is generally 210-240°C; filling rate is 20%; layer thickness is 0.1mm, and idling speed is generally 150mm / s.

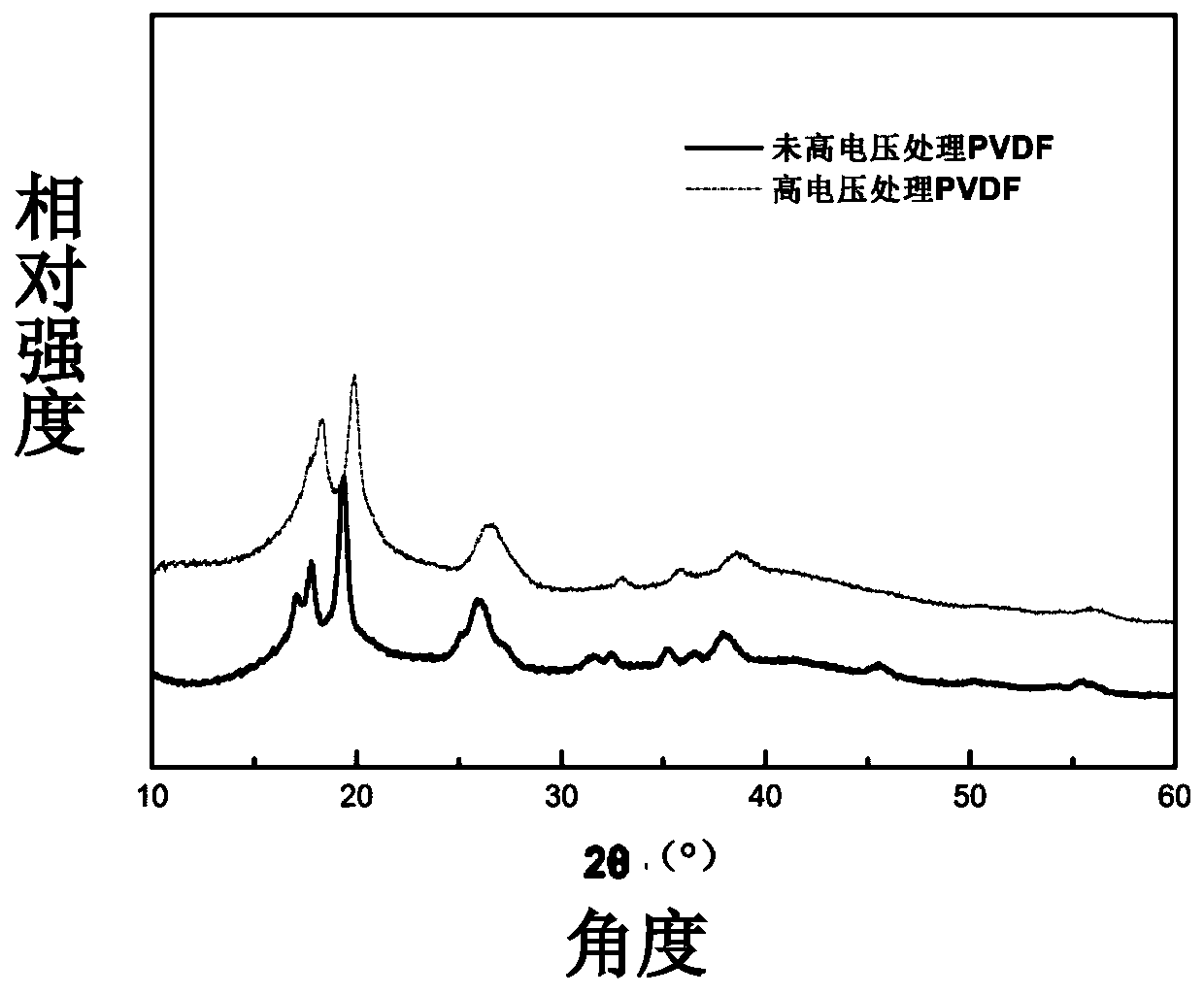

[0035] figure 2 It is a comparison chart of crystal form changes of the product prepared according to Example 1 of the present invention tested by X-ray diffraction, as shown in figure 2 As shown, it can be seen from the fi...

Embodiment 2

[0037] 1) Feeding: Feed pyroelectric materials such as polychlorotrifluoroethylene (PCTFE) wire into the nozzle of the 3D printer and clamp it tightly. Set the temperature of the nozzle to 240°C, the outer diameter of the nozzle to 0.3mm, and the distance between the nozzle and the collection platform The distance is 0.1mm;

[0038] 2) Connect to the high-voltage power supply: Connect the two poles of the high-voltage power supply to the nozzle of the 3D printer and the collection platform respectively, set the high voltage value, and the voltage value is 100V;

[0039] 3) Set process parameters: feed speed is generally 20mm / s; nozzle temperature is generally 210-240°C; filling rate is 20%; layer thickness is 0.1mm, and idling speed is generally 150mm / s.

[0040] The prepared product is tested by X-ray diffraction, and it is found that the crystal form changes.

Embodiment 3

[0042] 1) Feeding: Feed pyroelectric materials such as polyvinyl fluoride (PVF) wire into the nozzle of the 3D printer and clamp it tightly. Set the temperature of the nozzle to 210°C, the outer diameter of the nozzle to 0.4mm, and the distance between the nozzle and the collection platform to be 0.05mm;

[0043] 2) Connect to the high-voltage power supply: Connect the two poles of the high-voltage power supply to the nozzle of the 3D printer and the collection platform respectively, set the high voltage value, and the voltage value is 200KV;

[0044] 3) Set process parameters: feed speed is generally 20mm / s; nozzle temperature is generally 210-240°C; filling rate is 20%; layer thickness is 0.1mm, and idling speed is generally 150mm / s.

[0045] The prepared product is tested by X-ray diffraction, and it is found that the crystal form changes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com