VOCs (Volatile Organic Chemicals) catalyst taking foam titanium as carrier and preparation method thereof

A titanium foam and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of easy shedding of active components, complicated preparation process, high processing cost, etc., and achieve the highest shedding rate Low cost, easy access to raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

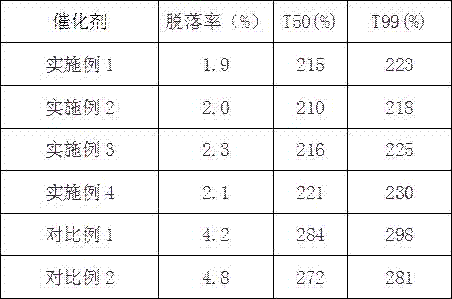

Examples

Embodiment 1

[0027] A titanium foam is used as a carrier and is used for catalytic oxidation of VOCs, prepared by the following steps:

[0028] 1) With 150mm×150mm and 1mm-thick porous metal titanium foam as the substrate, place it in 0.05mol / l oxalic acid solution for 10min and then place it in 10% dilute sulfuric acid solution for 60min, the reaction temperature is controlled at 70°C, the obtained product was repeatedly washed with deionized water to neutrality, and then dried at 80°C for 4 hours to generate a titanium dioxide precursor on the surface of the titanium foam and in the pores, and the titanium dioxide precursor was metatitanic acid;

[0029] 2) Calcinate the product obtained in step 1) at 400°C for 4 hours to obtain foamed titanium-titanium dioxide, use foamed titanium-titanium dioxide as a carrier, immerse it in 500ml of reaction solution and sonicate for 30 minutes, then put it in a muffle furnace and calcinate at 200°C, keep it warm 3h, obtain the catalyst that is used fo...

Embodiment 2

[0033] A titanium foam is used as a carrier and is used for catalytic oxidation of VOCs, prepared by the following steps:

[0034] 1) With 150mm×150mm and 2mm-thick porous metal titanium foam as the substrate, place it in 0.1mol / l oxalic acid solution for 5 minutes, then place it in 20% dilute sulfuric acid solution for 30 minutes, and control the reaction temperature at 90°C, the obtained product was washed repeatedly with deionized water until it was neutral, and then dried at 100°C for 2 hours to generate a titanium dioxide precursor on the surface of the foamed titanium and in the pores, and the titanium dioxide precursor was metatitanic acid;

[0035] 2) Calcinate the product obtained in step 1) at 600°C for 2 hours to obtain foamed titanium-titanium dioxide, use foamed titanium-titanium dioxide as a carrier, immerse in 500ml of reaction solution and ultrasonically for 60 minutes, then put it in a muffle furnace and calcinate at 300°C, keep it warm 2h, obtain the catalyst...

Embodiment 3

[0039] A titanium foam is used as a carrier and is used for catalytic oxidation of VOCs, prepared by the following steps:

[0040] 1) With porous metal titanium foam of 150mm×150mm and thickness of 2mm as the substrate, place it in 0.08mol / l oxalic acid solution for 8 minutes, then place it in 15% dilute sulfuric acid solution for 45 minutes, and control the reaction temperature at 80°C, the obtained product was repeatedly washed with deionized water until neutral, and then dried at 90°C for 3 hours to generate a titanium dioxide precursor on the surface and pores of the titanium foam, and the titanium dioxide precursor was metatitanic acid;

[0041]2) Calcinate the product obtained in step 1) at 500°C for 3 hours to obtain foamed titanium-titanium dioxide. Use foamed titanium-titanium dioxide as a carrier, immerse in 500ml of reaction solution and sonicate for 45 minutes, and then put it in a muffle furnace for calcination at 250°C. 2.5h, obtain the catalyst that is used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com