Palladium oxide complex for insulated cylinders and preparation method

A technology of palladium oxide and composites, which is applied in the field of palladium oxide composites and preparations for insulating gas cylinders, and can solve problems such as substandard air tightness of insulating gas cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

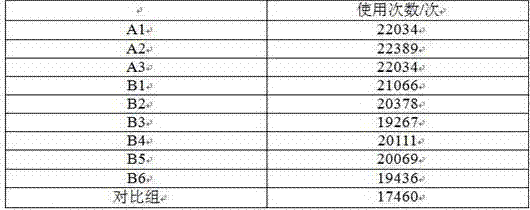

Examples

preparation example Construction

[0013] The invention provides a method for preparing a palladium oxide composite for an insulated gas cylinder, comprising:

[0014] 1) Paste reaction of palladium oxide, cyclodextrin and water to obtain pasting system;

[0015] 2) Add nickel source, tin source, neodymium oxide, dysprosium oxide, butyl lithium, cetyltrimethylammonium bromide, and hydrazine hydrate to the pasting system for hydrothermal reaction, then filter and dry to prepare get cured;

[0016] 3) The cured product is ball milled to prepare a palladium oxide composite for insulating gas cylinders.

[0017] In step 1) of the present invention, the amount of each material can be selected within a wide range, but in order to make the palladium oxide composite have more excellent hydrogen absorption capacity, preferably, in step 1), palladium oxide , cyclodextrin, water weight ratio is 10:4-7:20-30.

[0018] In step 1) of the present invention, the amount of each material can be selected in a wide range, but i...

Embodiment 1

[0029] 1) Paste reaction of palladium oxide (average particle size: 40nm), cyclodextrin, and water in a weight ratio of 10:5:25 (reaction temperature is 55°C, reaction time is 5h) to obtain a gelatinization system;

[0030] 2) Add nickel source (nickel acetate), tin source (tin tetrachloride), neodymium oxide, dysprosium oxide, butyllithium, cetyltrimethylammonium bromide, and hydrazine hydrate to the pasting system for Hydrothermal reaction (carried out in a closed environment, the reaction temperature is 160 ° C, the reaction time is 7 hours), then filtered and dried (the drying temperature is 105 ° C, the drying time is 2.5 hours) to obtain a cured product (gelatinization system, The weight ratio of nickel source, tin source, neodymium oxide, dysprosium oxide, butyllithium, cetyltrimethylammonium bromide, and hydrazine hydrate is 100:10:3:0.5:0.4:0.09:3:13);

[0031] 3) Ball mill the cured product (the mass ratio of large balls to small balls is 2:1, the mass ratio of grind...

Embodiment 2

[0033] 1) Paste reaction of palladium oxide (average particle size: 30nm), cyclodextrin, and water in a weight ratio of 10:4:20 (reaction temperature is 50°C, reaction time is 4h) to obtain a gelatinization system;

[0034] 2) Add nickel source (nickel nitrate), tin source (tributyltin chloride), neodymium oxide, dysprosium oxide, butyllithium, cetyltrimethylammonium bromide, and hydrazine hydrate to the pasting system To carry out hydrothermal reaction (in a closed environment, the reaction temperature is 140 ° C, the reaction time is 6 hours), and then filtered and dried (the drying temperature is 100 ° C, the drying time is 2 hours) to obtain a cured product (paste system , nickel source, tin source, neodymium oxide, dysprosium oxide, butyllithium, cetyltrimethylammonium bromide, and hydrazine hydrate in a weight ratio of 100:8:2:0.2:0.3:0.05:2:11) ;

[0035] 3) Ball mill the cured product (the mass ratio of large balls to small balls is 2:0.8, the mass ratio of grinding b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com