Molecular sieve composite material for heat insulation air bottle and preparation method

A composite material and molecular sieve technology, which is applied in the field of molecular sieve composite materials for insulating gas cylinders and its preparation, and can solve the problems of substandard air tightness of thermal insulating gas cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

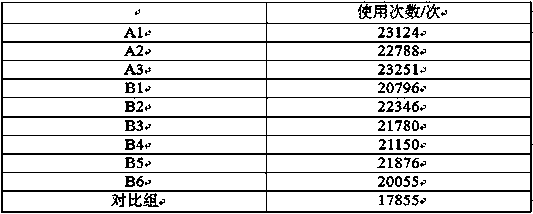

Image

Examples

preparation example Construction

[0013] The invention provides a method for preparing a molecular sieve composite material for insulating gas cylinders, comprising:

[0014] 1) Molecular sieves, hydrochloric acid, and sodium dodecylbenzenesulfonate are activated to obtain an activation system;

[0015] 2) Add magnesium source, palladium source, neodymium oxide, dysprosium oxide, butyllithium, urea, and sodium borohydride to the activation system for hydrothermal reaction, then filter and dry to obtain a cured product;

[0016] 3) The cured product is ball-milled to obtain a molecular sieve composite material for insulating gas cylinders.

[0017] In step 1) of the present invention, the amount of each material can be selected within a wide range, but in order to make the prepared molecular sieve composite material have more excellent hydrogen absorption capacity, preferably, in step 1), molecular sieve, hydrochloric acid , the weight ratio of sodium dodecylbenzenesulfonate is 10:2-3:0.2-0.5; and, the pH of t...

Embodiment 1

[0029] 1) Molecular sieve (average particle size is 0.3mm), hydrochloric acid, sodium dodecylbenzenesulfonate according to 10:2.5:0.4; and the pH of the hydrochloric acid is 5.5 for activation reaction (reaction temperature is 55 ℃, the reaction time is 5h) to prepare the activated system;

[0030] 2) Add magnesium source (magnesium acetate), palladium source (palladium nitrate), neodymium oxide, dysprosium oxide, butyllithium, urea, sodium borohydride to the activation system for hydrothermal reaction (in a closed environment, The reaction temperature is 210°C, the reaction time is 7h), and then filtered and dried (the drying temperature is 105°C, the drying time is 2.5h) to obtain a cured product (activation system, magnesium source, palladium source, neodymium oxide, dysprosium oxide, The weight ratio of butyllithium, urea and sodium borohydride is 100:20:5:0.3:0.4:0.12:7.5:20);

[0031] 3) Ball mill the cured product (the mass ratio of large balls to small balls is 2:1, t...

Embodiment 2

[0033] 1) Molecular sieve (average particle size is 0.2mm), hydrochloric acid, sodium dodecylbenzenesulfonate according to 10:2:0.2; and the pH of the hydrochloric acid is 5 for activation reaction (reaction temperature is 50 ℃, the reaction time is 4h) to prepare the activated system;

[0034] 2) Add magnesium source (magnesium nitrate), palladium source (palladium dichloride), neodymium oxide, dysprosium oxide, butyllithium, urea, sodium borohydride to the activation system for hydrothermal reaction (in a closed environment The reaction temperature is 200°C, the reaction time is 6h), and then filtered and dried (the drying temperature is 100°C, the drying time is 2h) to obtain the cured product (activation system, magnesium source, palladium source, neodymium oxide, dysprosium oxide , butyllithium, urea, and sodium borohydride in a weight ratio of 100:15:4:0.1:0.3:0.1:7:18);

[0035] 3) Ball mill the cured product (the mass ratio of large balls to small balls is 2:0.8, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com