A kind of complete denture and preparation method thereof

A technology for complete dentures and dentures, which is applied in the field of oral restoration, can solve the problems that the retention of dentures has not improved, the retention of complete dentures cannot provide retention, and the overall adsorption effect has weakened, so as to achieve hydrophobicity and strong retention. Force, improve the effect of retention force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

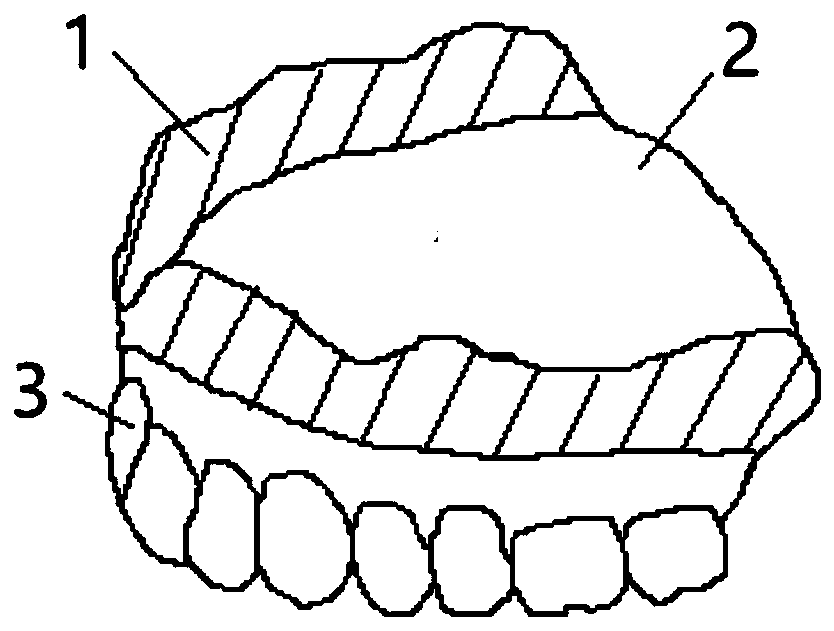

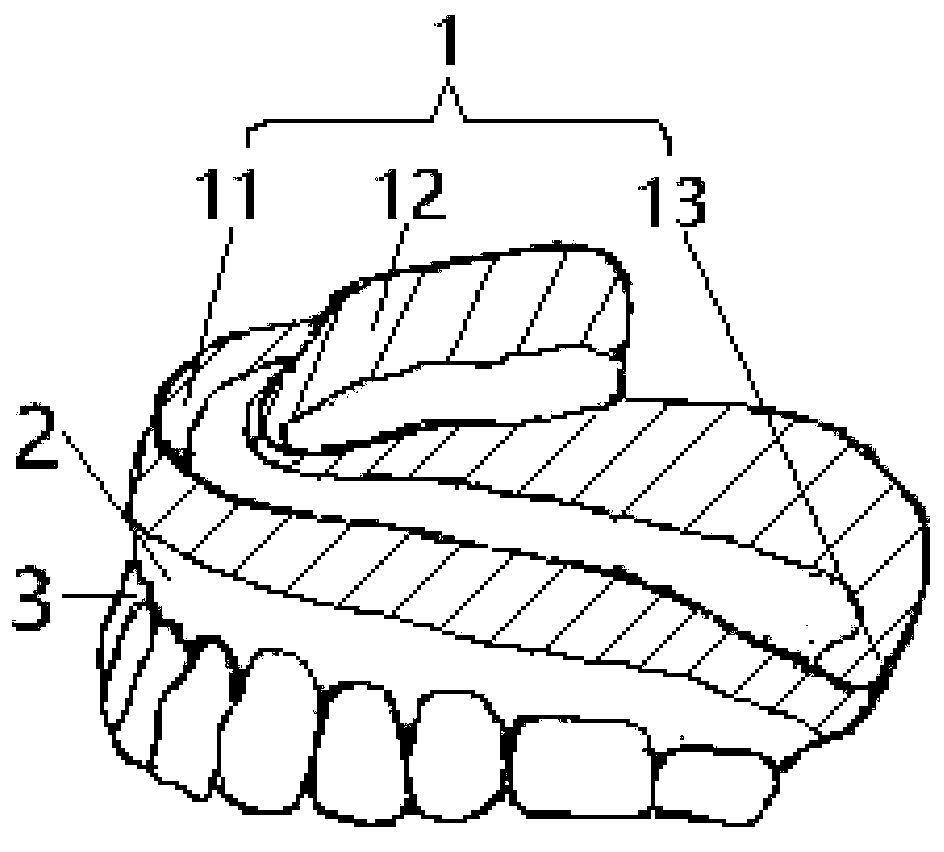

[0053] A complete denture, including upper and lower dentures, both of which are equipped with bases and artificial teeth.

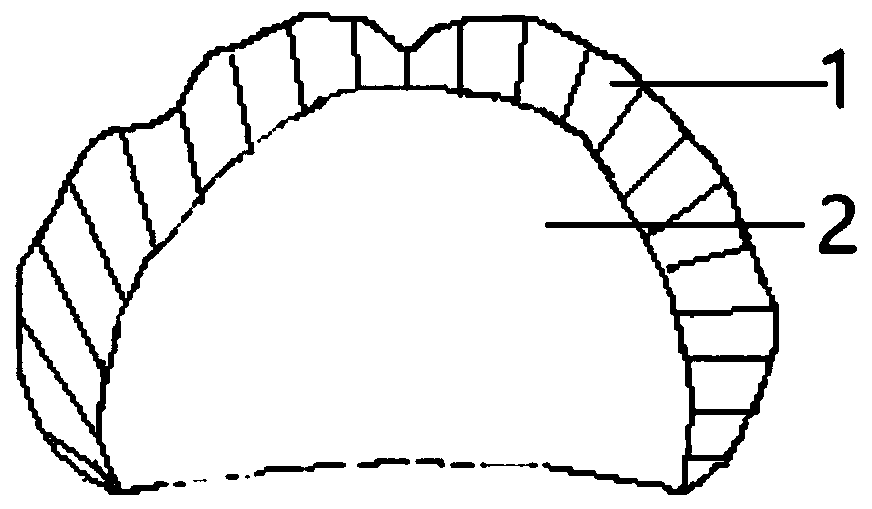

[0054] The base part of the maxillary denture includes the connected upper alveolar crest area and the palatal area of the alveolar crest. The artificial teeth are arranged in the base part of the upper alveolar crest area. The horizontal projection of the upper alveolar crest area is curved , the palatal area of the alveolar crest is located in the curved area of the upper alveolar crest; the base part outside the upper alveolar crest facing the oral cavity is made of silicone rubber; figure 1 , 2 , 5 shown.

[0055] The base part of the mandibular denture includes the lower alveolar crest area and the molar pad area. The artificial teeth are arranged in the base part of the lower alveolar crest area. It is located at the end of the curve of the lower alveolar crest area; the base part of the lower alveolar crest area facing the oral vestibule i...

Embodiment 2

[0058] A kind of complete denture, its structure is as described in embodiment 1, the difference is that one-third of the near end of the retromolar pad area is set as silicone rubber, such as image 3 , 4 .

Embodiment 3

[0060] A complete denture, the structure of which is as described in Embodiment 1, the difference is that the connecting surface of the base part made of silicone rubber and the base part made of non-silicone rubber is connected by a concave-convex head, and the base made of silicone rubber There are grooves on the connection surface of some parts, and bosses are provided on the connection surface of the base part made of non-silicone rubber, such as Figure 7 As shown, the groove is matched with the boss. The boss is a rectangular body, the groove is a rectangular groove, a cylindrical through hole is arranged on the boss, and the axis of the cylinder is parallel to the connecting surface; a cylindrical cylinder is correspondingly arranged on the groove, and the cylindrical cylinder is located in the cylindrical through hole. After thermocompression molding, the cylindrical body located in the cylindrical through hole is integrated with other surrounding silicone rubber, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com