Safe, simple, efficient and environment-friendly tar purification and solid waste treatment process

A technology for treating tar, applied in the petroleum industry, coke oven, combustible gas purification, etc., can solve the problems of artificial slag cleaning at the bottom of tar tanks, and achieve the effect of small footprint, improved tar recovery rate, and pollution solving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

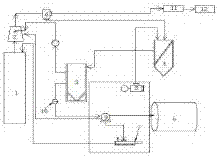

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] see as figure 1 As shown, the technical scheme adopted in this specific embodiment is: it comprises coke oven oven group 1, coke oven gas collecting pipe spraying 2, tar ammonia water separation tank 3, pre-separator 4, tar storage tank 5, gas-liquid separator 6, Tar slag conveying pump 7, tar squeeze pump 8, three-phase decanter centrifuge 9, centrifuge feed pump 10; the gas outlet of coke oven group 1 is connected to coke oven gas collecting pipe spraying 2, and the coke oven gas collecting pipe spraying 2 The outlet is connected to the gas-liquid separator 6, the coagulation liquid outlet of the gas-liquid separator 6 is connected to the pre-separator 4, the tar residue outlet of the pre-separator 4 is connected to the tar squeeze pump 8, and the outlet of the tar squeeze pump 8 is connected to the The pre-separator 4 is connected, and the liquid outlet of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com