Method for improving molybdenum concentrate recovery rate during copper-molybdenum separation of low-grade high-argillization skarn ore

A skarn copper-molybdenum, low-grade technology, applied in the field of improving the recovery rate of copper-molybdenum separation molybdenum concentrate from skarn copper-molybdenum ore, can solve the problem of low molybdenum recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Include the following steps:

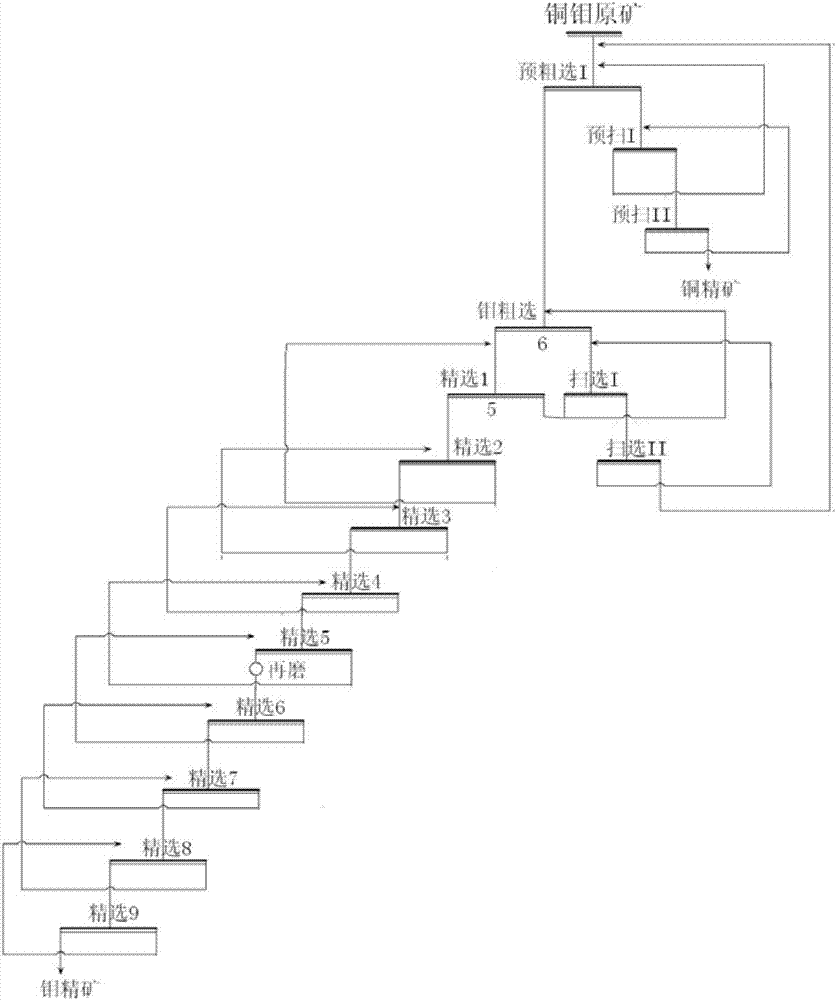

[0049] (1) Pre-tailing operation of mixed concentrate:

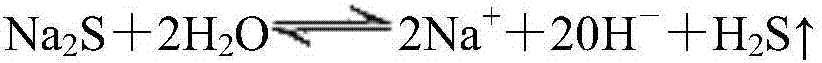

[0050] For low-grade high-mud skarn copper-molybdenum ore, which contains low molybdenum grade and gangue minerals are easy to muddy, in order to eliminate the influence of fine-grained gangue minerals on the subsequent separation and flotation of copper and molybdenum, a tailing is removed in advance. That is, copper concentrate, throwing away part of the fine-grained gangue in advance to enrich the molybdenum grade in the copper-molybdenum mixed concentrate, and adjusting the mass percentage concentration of the mixed concentrate slurry produced by the ore-copper-molybdenum mixed concentrate to 10%; Pre-selection and tailing roughing operation: add 1450g / t of sodium silicate mixed concentrate, 3900g / t of sodium hydrosulfide mixed concentrate, 90g / t of kerosene mixed concentrate to the slurry, stir for 4 minutes, flotation time of 6 minutes, foam Enter the copper-molybdenum separat...

Embodiment 2

[0058] Include the following steps:

[0059] (1) Pre-tailing operation of mixed concentrate:

[0060]For low-grade high-mud skarn copper-molybdenum ore, which contains low molybdenum grade and gangue minerals are easy to muddy, in order to eliminate the influence of fine-grained gangue minerals on the subsequent separation and flotation of copper and molybdenum, a tailing is removed in advance. That is, copper concentrate, throwing away part of the fine-grained gangue in advance to enrich the molybdenum grade in the copper-molybdenum mixed concentrate, and adjusting the mass percentage concentration of the mixed concentrate slurry produced by the ore-copper-molybdenum mixed concentrate to 11%; Pre-selection tailing roughing operation: Add 1500g / t mixed concentrate of water glass, 4000g / t mixed concentrate of sodium hydrogen sulfide, 100g / t kerosene mixed concentrate to the pulp, stir for 5 minutes, flotation time is 7 minutes, foam Enter the copper and molybdenum separation r...

Embodiment 3

[0068] Include the following steps:

[0069] (1) Pre-tailing operation of mixed concentrate:

[0070] For low-grade high-mud skarn copper-molybdenum ore, which contains low molybdenum grade and gangue minerals are easy to muddy, in order to eliminate the influence of fine-grained gangue minerals on the subsequent separation and flotation of copper and molybdenum, a tailing is removed in advance. That is, copper concentrate, throwing away part of the fine-grained gangue in advance, so that the molybdenum grade in the copper-molybdenum mixed concentrate can be enriched, and the mass percentage concentration of the mixed concentrate slurry produced by the copper-molybdenum mixed concentrate output is adjusted to 12%; Pre-selection and tailing roughing operation: add 1550g / t of sodium silicate mixed concentrate, 4100g / t of sodium hydrosulfide mixed concentrate, 110g / t of kerosene mixed concentrate to the slurry, stir for 6 minutes, flotation time of 8 minutes, foam Enter the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com