Hybrid mechanism film and preparation method thereof

A kind of mechanism and thin film technology, applied in the field of mixed mechanism membrane and its preparation, can solve the problems of hybrid membrane limitations and few types, and achieve the effect of simple production method, low cost and high gas selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of above-mentioned mixing mechanism film, comprises the following steps:

[0038] Step 1. Dissolving the soluble intrinsic microporous polymer in chloroform and stirring evenly, and filtering with a microporous membrane to obtain a filtrate;

[0039] Among them, the soluble intrinsic microporous polymer is a prior art, and can be obtained by means known to those skilled in the art; the amount of chloroform is not particularly limited, as long as it can achieve the purpose of dissolution, usually the mass ratio of the soluble intrinsic microporous polymer to chloroform It is 90mg: 2.5g, the stirring time generally needs 10-60min, the stirring speed is 300r / min, and the micropore of the microporous membrane is less than 4 microns earlier.

[0040] Step 2, adding the metal-organic framework material into chloroform and stirring evenly to obtain a solution;

[0041] Among them, the amount of chloroform is not particularly limited, as long as the purp...

Embodiment 1

[0053] Step 1, take 60mg Eu(NO 3 ) 3 ·6H 2 O, 20 mg H 3 BTC and 40.8mg NaAc·3H 2 O, add 10ml of DMF and 2ml of ethanol to the mixed solution, and react at 60°C for 5h to obtain JUC-32, which is the MOF material;

[0054] Step 2, take 90mg of PIM-1, dissolve in 2.5g of chloroform solution, stir for 30min to mix evenly, filter with microporous membrane to obtain filtrate;

[0055] Step 3: Take 10 mg of JUC-32 obtained in Step 1, dissolve it in 2.5 g of chloroform solution, and stir evenly to obtain a solution;

[0056] Step 4. Mix the filtrate of step 2 and the solution of step 3 and sonicate for 10 minutes to fully mix PIM-1 and JUC-32, and continue to stir for 12 hours to obtain a mixed solution;

[0057] Step 5. Apply the mixed solution obtained in Step 4 evenly on the surface of the porous silica film, and control the solvent to evaporate completely at 20° C. for 48 hours;

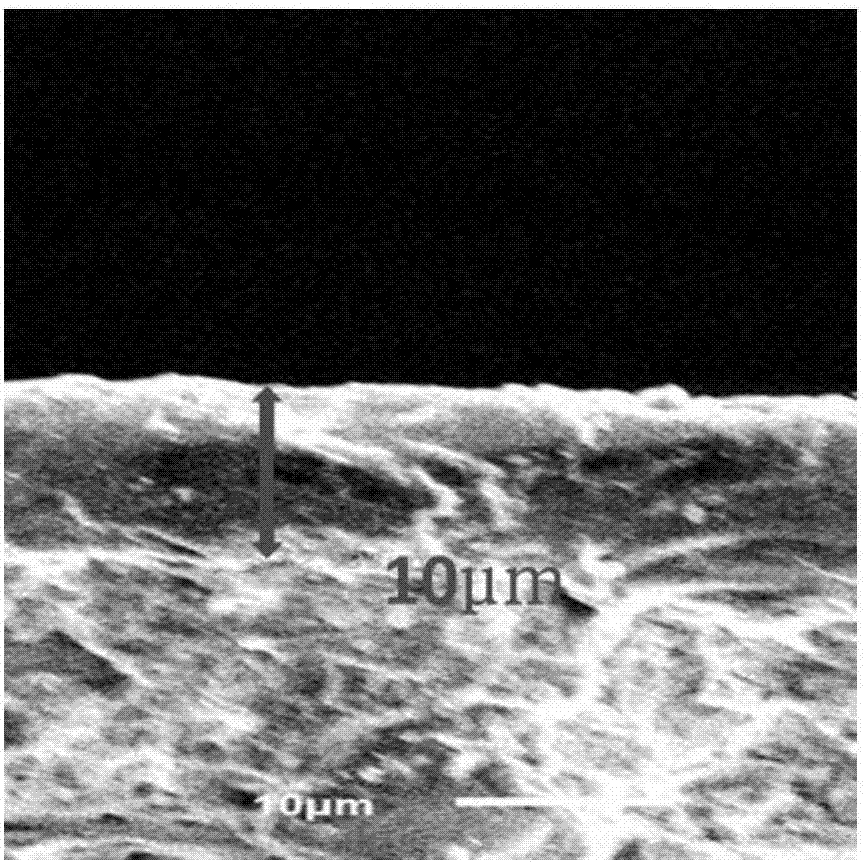

[0058] Step 6. Repeat step 5 and three times to obtain a uniform and continuous mixing mechanis...

Embodiment 2

[0060] The method of this example is basically the same as that of Example 1, except that 80 mg of PIM-1 is taken in step 2, and 20 mg of JUC-32 is taken in step 3 for mixing, and the synthesized film is recorded as 20% JUC-32@PIM-1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com