Filler assembly capable of eliminating amplification effect

A component and effect technology, applied in distillation separation, chemical/physical/physicochemical process, fractionation, etc., to eliminate the effect of liquid wall flow, reduce investment, and simplify design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

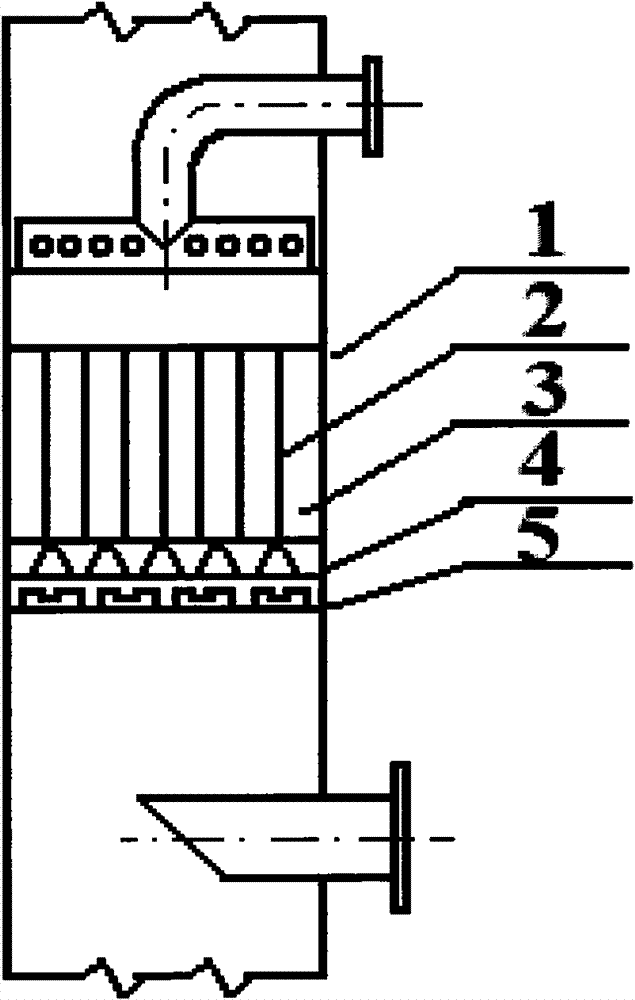

[0038] The packing assembly described in the present invention that can eliminate the amplification effect uses the reality that "small towers have no amplification effect, but large towers have amplification effects and increase sharply with the increase of the tower diameter". It is proposed to connect multiple packing units in parallel Construct a new configuration of large packed tower. The application of the present invention in the packed tower figure 1 .

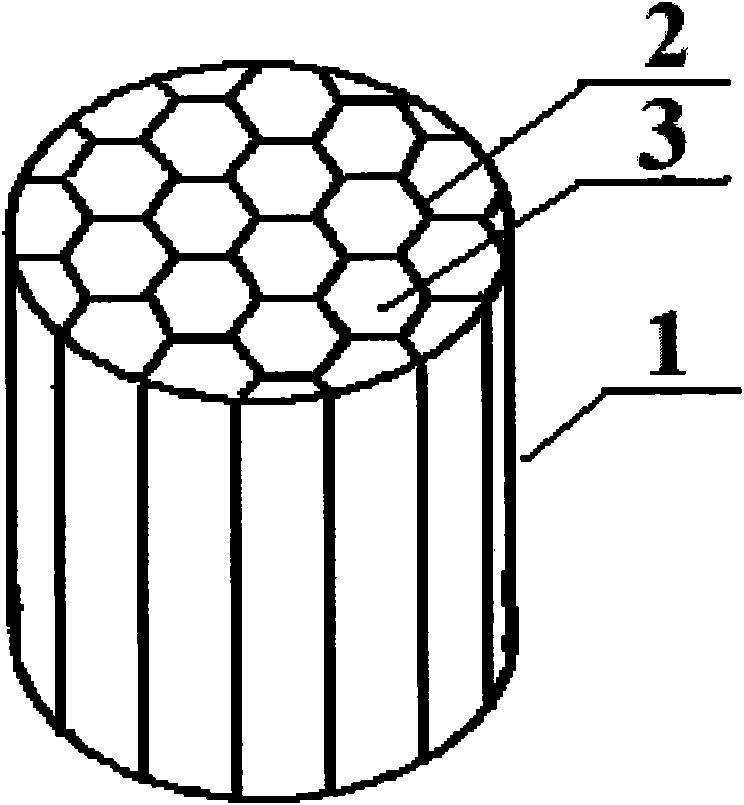

[0039] The packing assembly of the present invention includes a packing section 1, a packing partition 2, a packing unit 3, a packing support plate 4 and a liquid redistribution plate 5. The packing partition 2 divides the packing section 1 into a plurality of parallel packing units 3 at regular intervals. A layer of packing support plate 4 and a liquid redistribution plate 5 are arranged at the bottom of the high packing section 1. The structure of the packing section 1 of the present invention is shown, see figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com