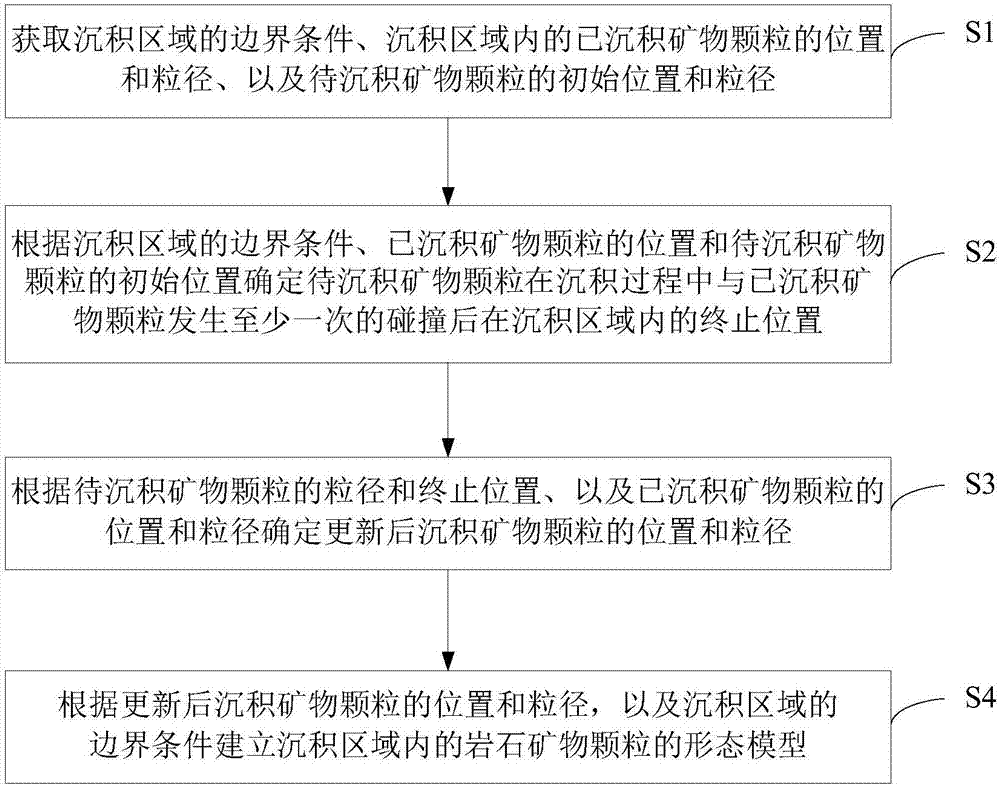

Digital rock physical model construction method and device

A petrophysical model and construction method technology, applied in the field of digital petrophysical model construction, can solve problems such as insufficient consideration, high cost, and difficulty in satisfying actual production, and achieve the effect of improving authenticity and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

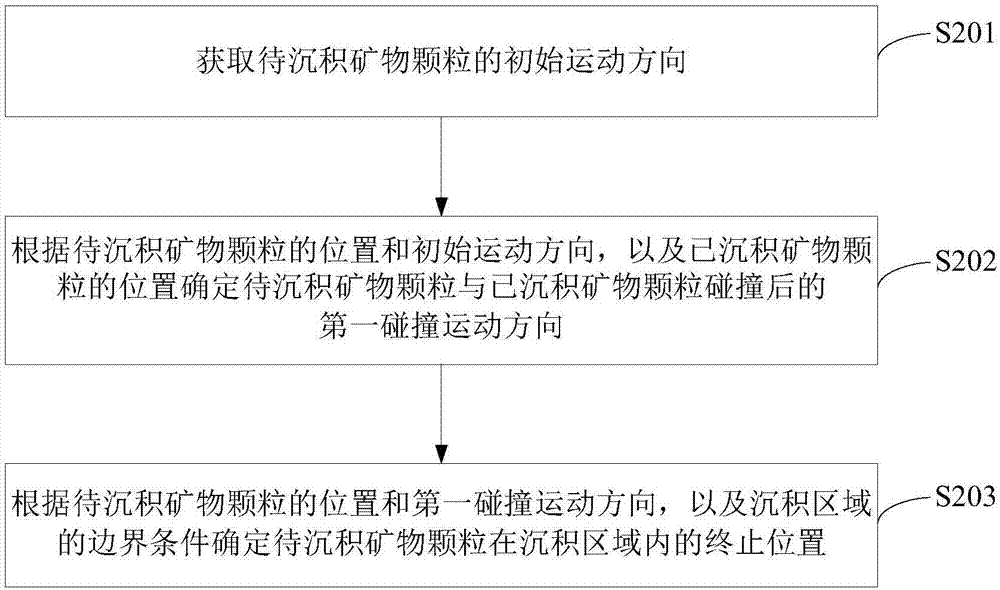

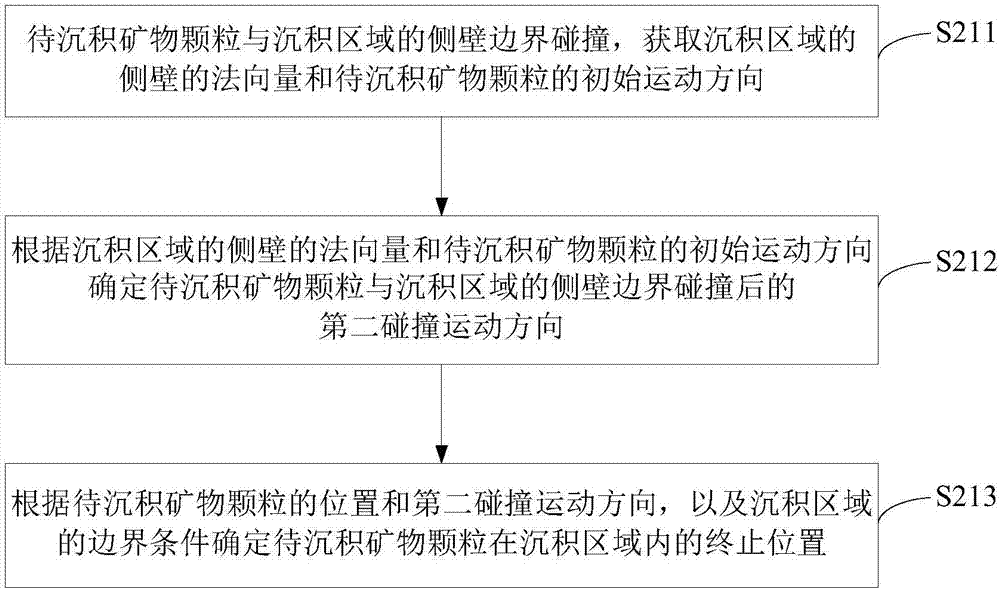

Method used

Image

Examples

Embodiment 2

[0097] Figure 10 is a schematic structural diagram of the digital rock physics model construction device provided by Embodiment 2 of the present invention, as Figure 10 As shown, on the basis of the first embodiment above, the present invention also provides a digital petrophysical model construction device 4, including:

[0098] The acquisition module 41 is configured to acquire the boundary conditions of the deposition area, the position and particle size of the deposited mineral particles in the deposition area, and the initial position and particle size of the mineral particles to be deposited.

[0099] It should be noted that when the acquisition module 41 of this embodiment acquires the above information, the boundary conditions of the deposition area, the position and particle size of the deposited mineral particles in the deposition area, and the initial position and particle size of the mineral particles to be deposited All can be set according to actual needs, whi...

Embodiment 3

[0107] also, Figure 11 It is a schematic structural diagram of the digital rock physics model construction device provided by Embodiment 3 of the present invention. Such as Figure 11 As shown, on the basis of the first and second embodiments above, the third embodiment of the present invention provides a digital petrophysical model construction device 5, which includes:

[0108] The memory 51 is used to store instructions; specifically, the storage objects of the memory 52 include software and modules. The processor 52 is configured to execute the instructions stored in the memory 51 to execute the digital petrophysical model construction method provided in the first embodiment above. The processor 52 executes various functions of the digital petrophysical model building device 5 and processes data by running or executing software programs and / or modules stored in the memory 51 and calling data stored in the memory 51 .

[0109] Specifically, the processor 52 is configure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com