System and method for calibrating aircraft overload sensor system level installation error

An overload sensor and installation error technology, applied in instruments, measuring devices, etc., can solve problems such as the influence of pneumatic parameter identification, the inconsistency between the measured value of overload and the real value, etc., and achieve the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

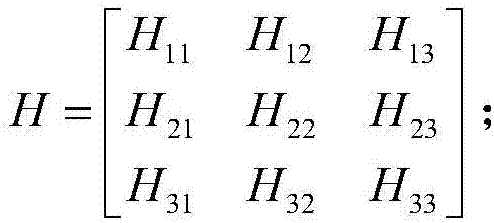

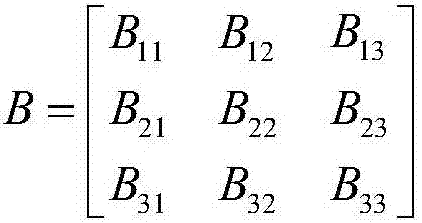

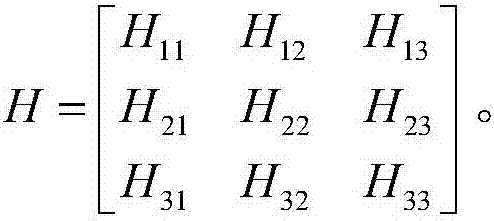

[0065] Taking an aircraft with a high lift-to-drag ratio as an example, the transformation matrix C of the sensor relative to the aircraft coordinate system and the corresponding installation deviation are obtained.

[0066] An aircraft overload sensor system-level installation error calibration method, a reference corner block is installed on the outer surface of the aircraft to provide a measurement reference for the shape of the aircraft, the reference corner block is a standard orthogonal instrument, composed of two perpendicular surfaces Composition, respectively A leaning on the face and B leaning on the face; The steps of the method include:

[0067] (1) Establish a coordinate system, including establishing the aircraft coordinate system OX1Y1Z1, the overload sensor sensitive axis coordinate system OmXmYmZm and the reference corner block coordinate system OdXdYdZd;

[0068] Among them, the aircraft coordinate system OX1Y1Z1: the coordinate origin O is the center of mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com