Camellia oleifera meal polypeptide, preparation method and application in cryopreservation of bovine semen

A technology of camellia oleifera meal polypeptide and cryopreservation, which is applied in the field of animal husbandry, can solve the problems that have not yet been reported on the in-depth development of hydrolyzed polypeptide of small fruit camellia oleifera meal, and achieve the effect of realizing waste reuse, easy implementation, and reducing oxidative damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

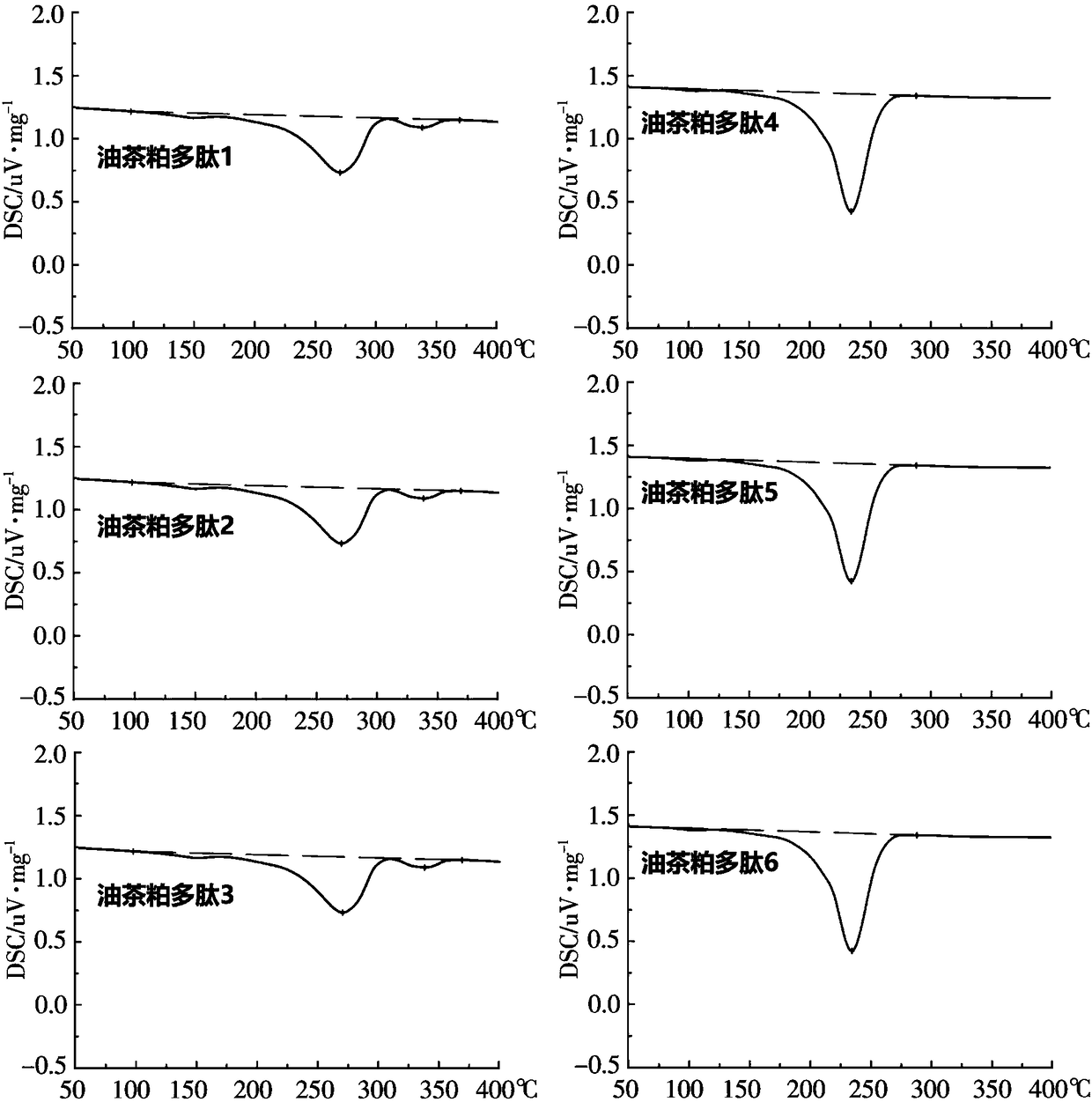

[0046] Example 1: Preparation of camellia oleifera meal polypeptide 1 by trypsin

[0047] Including the following steps:

[0048] Step S1, pulverize the small fruit oil tea meal to 80-100 mesh, add water to soak overnight, and finally make a meal powder suspension, the mass concentration of the meal powder suspension is 150g / L;

[0049] Step S2, adding trypsin for enzymatic hydrolysis (the added weight is 3.0g / 100g based on the weight of meal powder), the enzymatic hydrolysis conditions are: pH value, 8.0; enzymatic hydrolysis temperature, 45°C; enzymatic hydrolysis time, 11 hours; end of enzymatic hydrolysis Afterwards, heat treatment at 90°C for 10 minutes to inactivate trypsin, cool to room temperature, let stand to take the supernatant;

[0050] Step S3, filtering the supernatant with absorbent cotton for 3 times, collecting and merging the filtrate, and freeze-drying to obtain a crude freeze-dried powder;

[0051] Step S4, dissolve the crude freeze-dried powder with ult...

Embodiment 2

[0052] Example 2: Preparation of camellia oleifera meal polypeptide 2 by trypsin

[0053] Including the following steps:

[0054] Step S1, pulverize the small fruit oil tea meal to 80-100 mesh, add water to soak overnight, and finally make a meal powder suspension, the mass concentration of the meal powder suspension is 130g / L;

[0055] Step S2, adding trypsin for enzymatic hydrolysis (the added weight is 2.5g / 100g based on the weight of meal flour), the enzymatic hydrolysis conditions are: pH value, 7.8; enzymatic hydrolysis temperature, 43°C; enzymatic hydrolysis time, 12 hours; end of enzymatic hydrolysis Afterwards, heat treatment at 90°C for 10 minutes to inactivate trypsin, cool to room temperature, let stand to take the supernatant;

[0056] Step S3, filtering the supernatant with absorbent cotton for 3 times, collecting and merging the filtrate, and freeze-drying to obtain a crude freeze-dried powder;

[0057] Step S4, the crude freeze-dried powder is dissolved in ul...

Embodiment 3

[0058] Example 3: Preparation of camellia oleifera meal polypeptide 3 by trypsin

[0059] Including the following steps:

[0060] Step S1, pulverize the small fruit oil tea meal to 80-100 mesh, add water to soak overnight, and finally make a meal powder suspension, the mass concentration of the meal powder suspension is 170g / L;

[0061] Step S2, adding trypsin for enzymatic hydrolysis (the added weight is 3.5g / 100g based on the weight of meal powder), the enzymatic hydrolysis conditions are: pH value, 8.2; enzymatic hydrolysis temperature, 47°C; enzymatic hydrolysis time, 10 hours; end of enzymatic hydrolysis Afterwards, heat treatment at 90°C for 10 minutes to inactivate trypsin, cool to room temperature, let stand to take the supernatant;

[0062] Step S3, filtering the supernatant with absorbent cotton for 3 times, collecting and merging the filtrate, and freeze-drying to obtain a crude freeze-dried powder;

[0063] Step S4, the crude freeze-dried powder is dissolved in ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com