Crack-resistant high thermal conductivity mortar and preparation method and application thereof

A high thermal conductivity, mortar technology, applied in the field of building materials, can solve the problems of poor thermal conductivity of aluminum film, active ion corrosion, high price, etc., and achieve the effects of fast heat transfer, simple preparation process, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

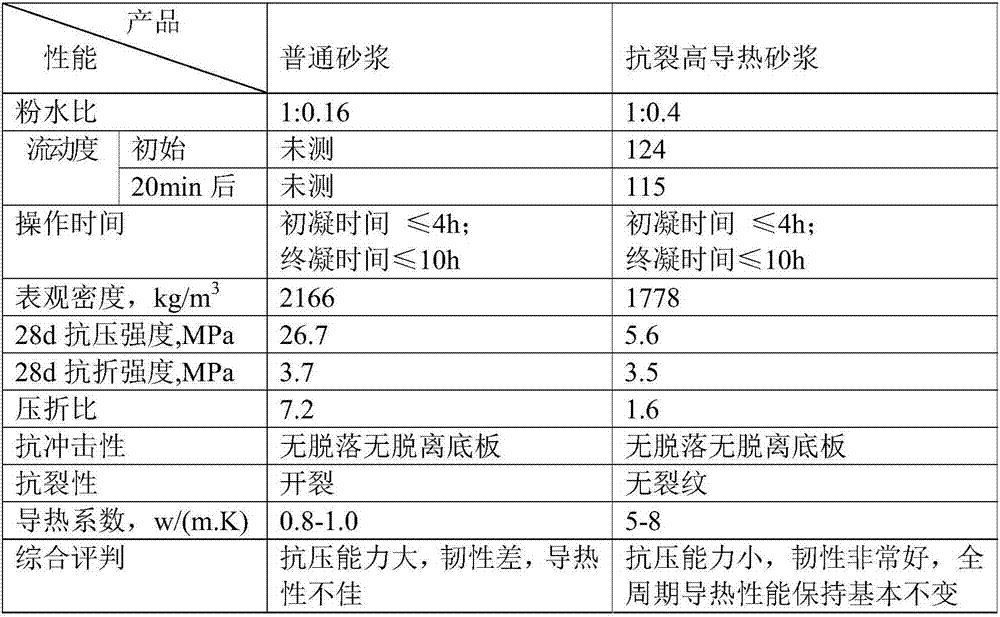

Embodiment 1

[0031] A crack-resistant high thermal conductivity mortar, comprising the following components: 100 parts of cement, 90 parts of filler aggregate, 60 parts of thermal conductive material, 0.5 part of carbon fiber, and 3 parts of admixture.

[0032] Among them, the cement is Portland hydrochloric acid cement with a strength grade of 42.5; the filler aggregate is quartz sand and tailings with a weight ratio of 1:1, and the particle size of the quartz sand is 1mm; the heat-conducting material is graphite powder with a weight ratio of 3:1.5 and iron filings; admixtures include water-reducing agent, water-retaining agent, binder with a weight ratio of 1:1.5:10, water-reducing agent polycarboxylic acid, water-retaining agent is hydroxypropyl cellulose, and binder is ethylene-acetic acid Ethylene copolymer powder.

[0033] When preparing, mix Portland cement, graphite powder, iron filings, polycarboxylic acid, hydroxypropyl cellulose, ethylene-vinyl acetate copolymer rubber powder, s...

Embodiment 2

[0035] A crack-resistant high thermal conductivity mortar comprises the following components: 100 parts of cement, 70 parts of filler aggregate, 80 parts of thermal conductive material, 1.25 parts of carbon fiber, and 2 parts of admixture.

[0036] Among them, the cement is Portland hydrochloric acid cement with a strength grade of 42.5; the filler aggregate is quartz sand and tailings with a weight ratio of 1:0.8, and the particle size of the quartz sand is 0.5mm; the heat-conducting material is graphite with a weight ratio of 3:1 powder and aluminum chips; admixtures include water reducing agent, water retaining agent, binder with a weight ratio of 1:2:8, water reducing agent polycarboxylic acid, water retaining agent is hydroxypropyl cellulose, binder is ethylene- Vinyl acetate copolymer powder.

[0037] When preparing, mix Portland cement, graphite powder, aluminum chips, polycarboxylic acid, hydroxypropyl cellulose, and ethylene-vinyl acetate copolymer rubber powder, stir e...

Embodiment 3

[0039] A crack-resistant high heat conduction mortar, comprising the following components: 100 parts of cement, 100 parts of filler aggregate, 50 parts of heat conduction material, 0.125 parts of carbon fiber, and 3.75 parts of admixture.

[0040] Among them, the cement is Portland hydrochloric acid cement with a strength grade of 42.5; the filler aggregate is quartz sand and tailings with a weight ratio of 1:1.2, and the particle size of the quartz sand is 0.1mm; the heat-conducting material is graphite with a weight ratio of 3:1.2 Powder and steel slag powder; admixtures include water reducing agent, water retaining agent, binder with a weight ratio of 1:1:9, water reducing agent polycarboxylic acid, water retaining agent is hydroxypropyl cellulose, binder is ethylene- Vinyl acetate copolymer powder.

[0041] When preparing, mix Portland cement, graphite powder, steel slag powder, polycarboxylic acid, hydroxypropyl cellulose, ethylene-vinyl acetate copolymer rubber powder, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com