Bin penetrating structure for cable sealing

A cable and cabin technology, applied in electrical components, coupling devices, circuits, etc., can solve the problems of miniaturization and light weight of the whole machine, bulky watertight connectors, high price, high reliability, flexible installation and use Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is aimed at the transmission of power electricity between the underwater propulsion motor control driver and the motor;

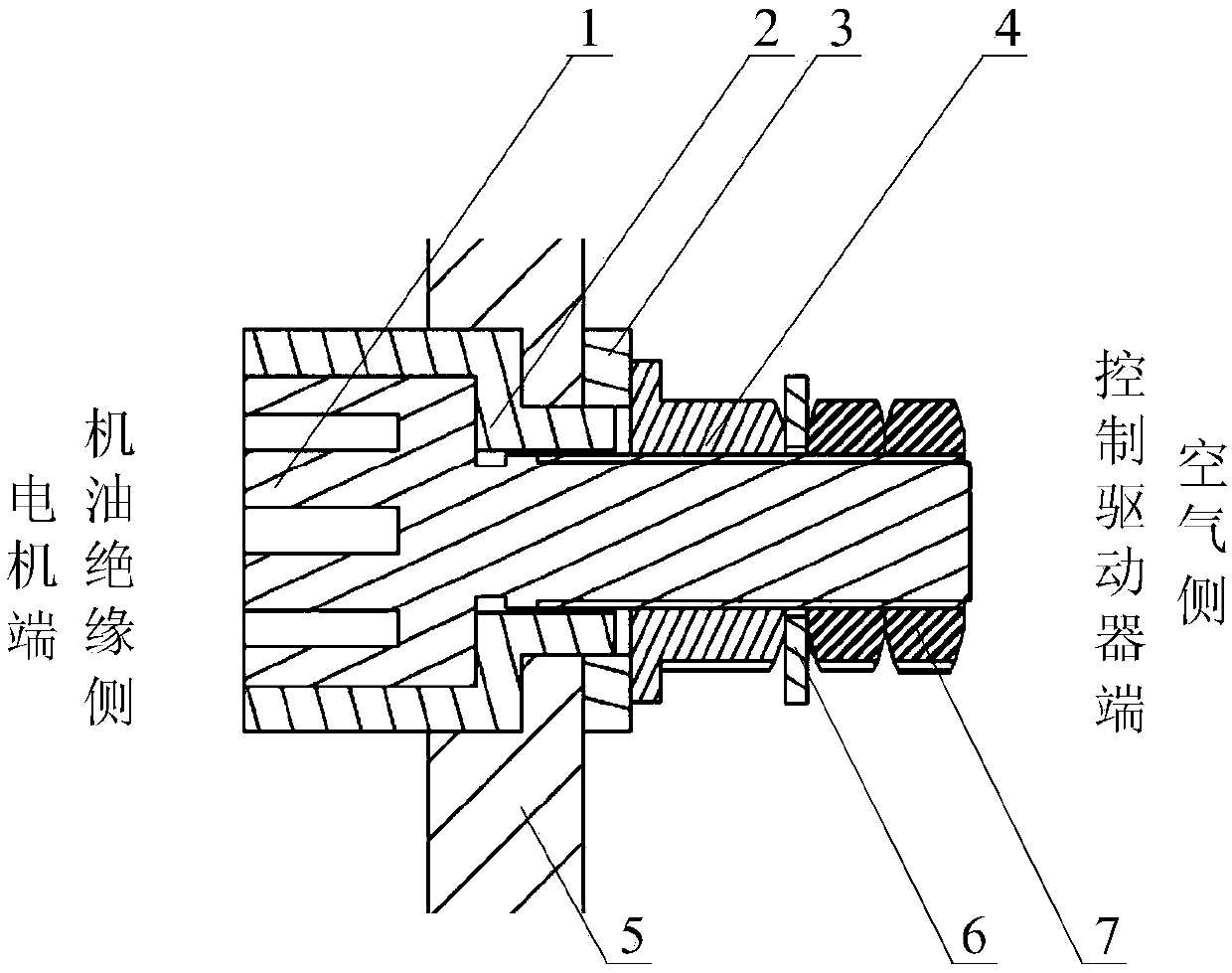

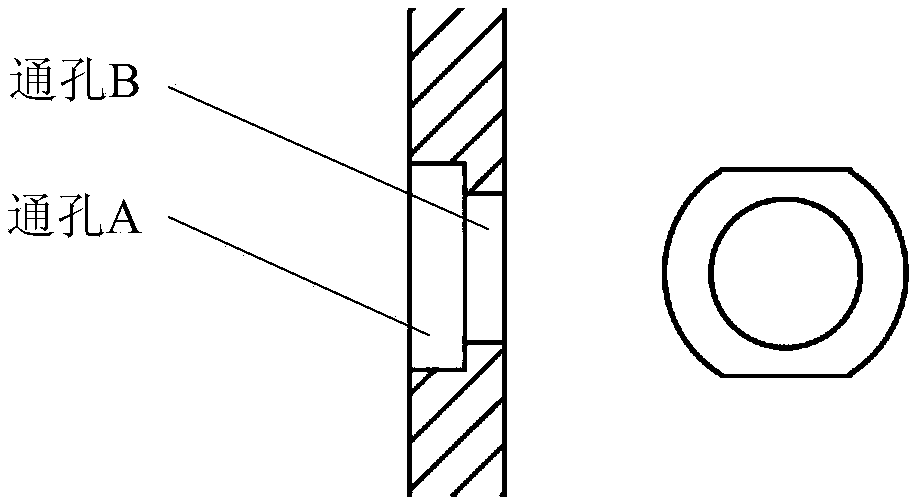

[0049] like figure 1 As shown in the figure, a cable sealing penetration structure is used for the sealing of cables between two compartments, the two compartments are respectively the motor compartment and the control drive compartment, and the two compartments are separated by a partition layer 5 for isolation; the medium in the motor compartment is oil insulating liquid, and the medium in the control drive compartment is air; the compartment 5 is a partition with stepped through holes, and the structural diagram of the compartment 5 is as follows figure 2 As shown, the stepped through hole includes a through hole A and a through hole B, the diameter of the through hole A is 26 mm, and the diameter of the through hole B is 16 mm; the top and bottom ends of the through hole A are milled flat;

[0050] The penetrating structure incl...

Embodiment 2

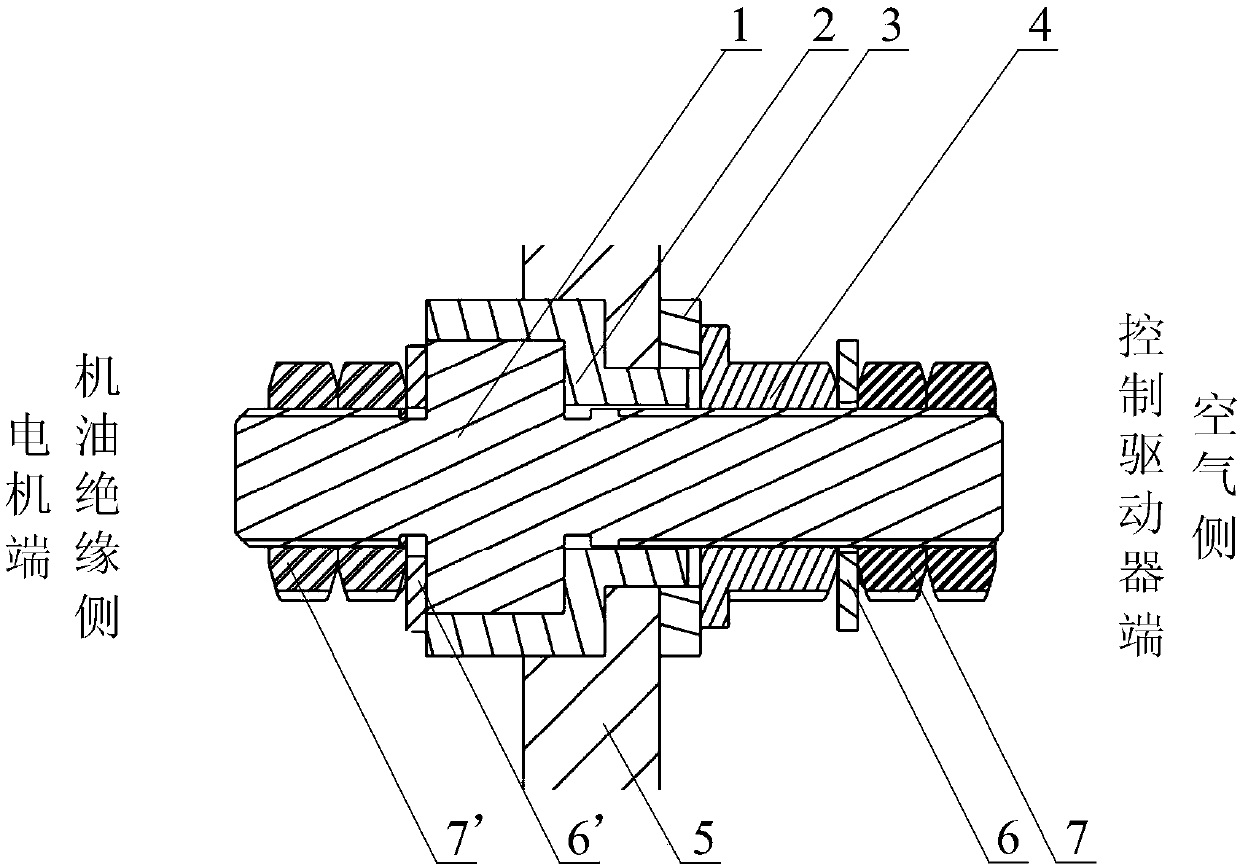

[0060] This embodiment is aimed at the transmission of power electricity between the underwater propulsion motor control driver and the motor;

[0061] like image 3 As shown in the figure, a cable sealing penetration structure is used for the sealing of cables between two compartments, the two compartments are respectively the motor compartment and the control drive compartment, and the two compartments are separated by a partition layer 5 for isolation; the medium in the motor compartment is oil insulating liquid, and the medium in the control drive compartment is air; the compartment 5 is a partition with stepped through holes, and the structural diagram of the compartment 5 is as follows figure 2 As shown, the stepped through hole includes a through hole A and a through hole B, the diameter of the through hole A is 26 mm, and the diameter of the through hole B is 16 mm; the top and bottom ends of the through hole A are milled flat;

[0062] The penetrating structure incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com