Ecological spray anchor slope protection structure and method

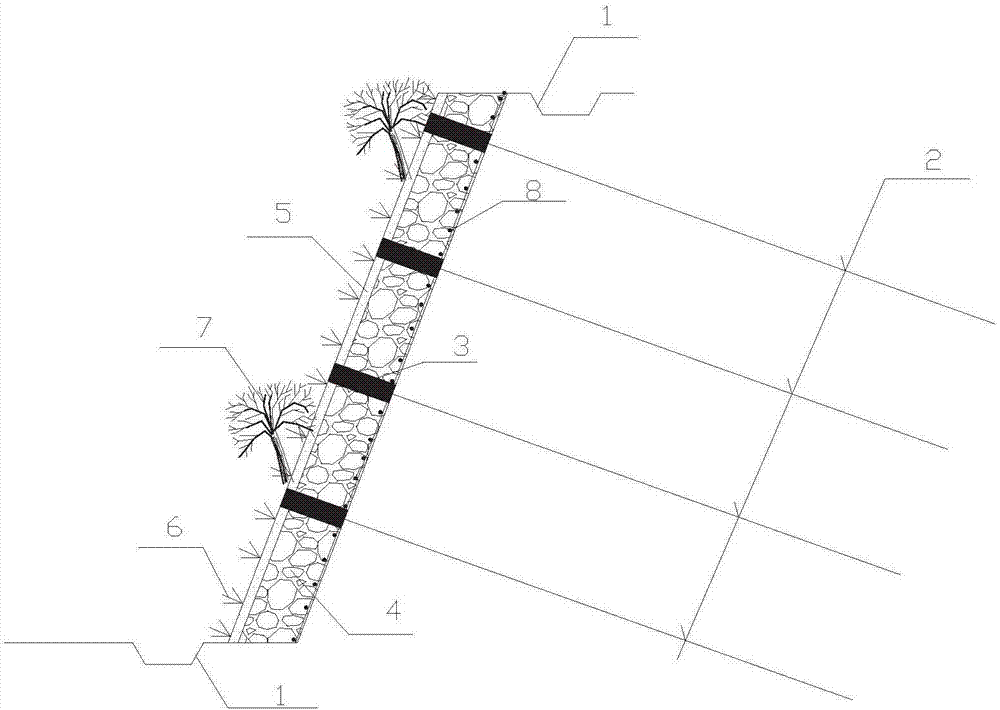

It is an ecological and slope technology, which is applied in the direction of infrastructure engineering, botanical equipment and methods, and excavation. It can solve the problems that it cannot be popularized and applied in a large area, the difficulty in obtaining materials such as urban sludge, and low construction efficiency. Good resistance, moderate strength and consistency, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] The embodiment of the present invention belongs to the protection of high and steep road slopes, the slope is about 75°, and the height is 20m. The construction is carried out by spraying (pumping) technology, including the following steps:

[0144] The first step is to level the slope, chisel out the protruding stones, and fill the sunken parts with soil to make the entire slope as smooth as possible.

[0145] The second step is to set up intercepting drainage ditches, and set intercepting drainage ditches at the top and foot of the slope to prevent excessive rainwater from scouring the slope. The drainage ditches can be built with concrete or mortar masonry, and the size of the drainage ditch is 500×300mm.

[0146] The third step is to drill and arrange anchor rods. The anchor rods use grade II steel bars with a diameter of 22mm and a spacing of 3m. They are arranged in a plum blossom shape, and the length of the anchor rods is 6m. The end of the anchor rod is sealed ...

Embodiment 2

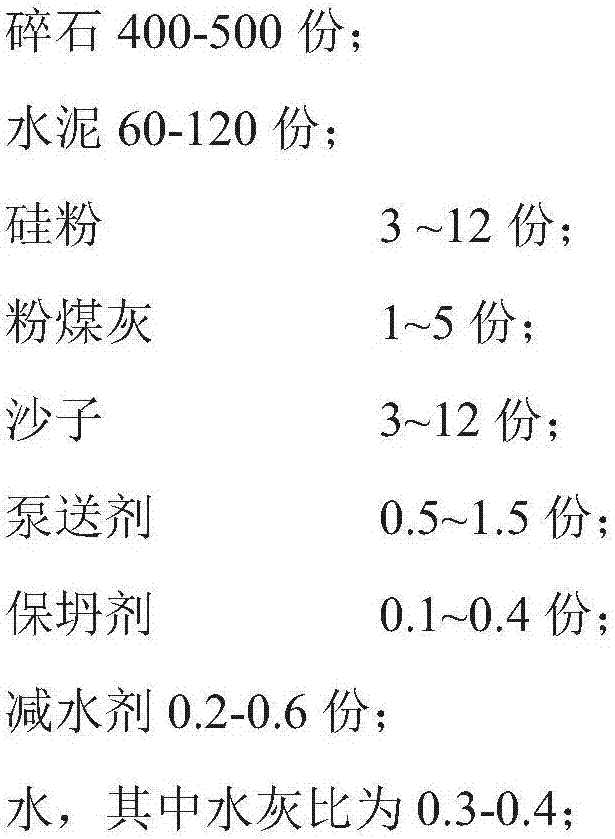

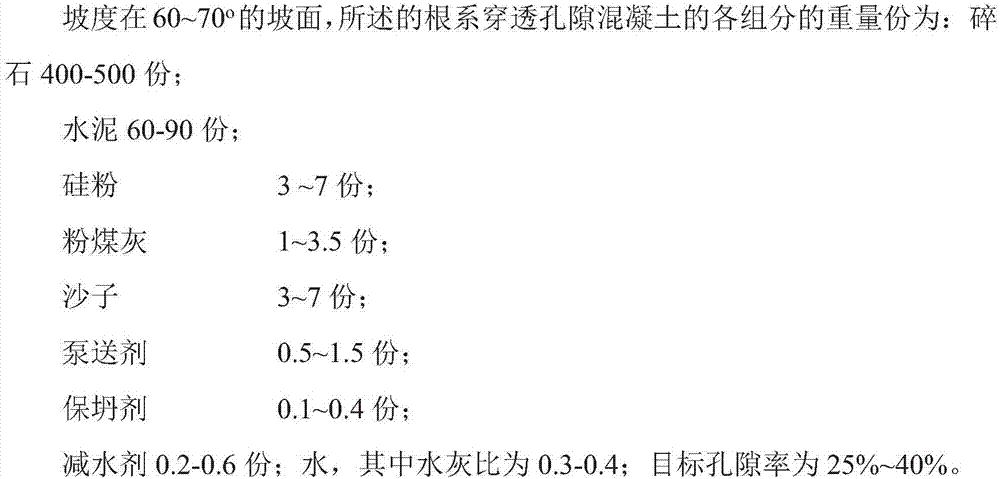

[0183] The embodiment of the invention belongs to road slope protection, with a slope of about 60° and a height of 20m.

[0184] Compared with embodiment 1, the difference only lies in the following points:

[0185] The first point: the fifth step is to spray the root system through the pores. The cementing material of the concrete consists of 90 parts of cement, 5 parts of silica fume, 2 parts of fly ash, 5 parts of sand, 0.8 parts of pumping agent, 0.2 parts of slump retaining agent, and water reducing agent. 0.4 parts of agent, water-cement ratio of 0.35, the target porosity of the root penetration pore concrete is determined to be 28%, and the weight ratio of each component in the pore concrete finally determined by calculation is 450 parts of crushed stone, 63.96 parts of cement, 3.55 parts of silicon fume, 1.42 parts of fly ash, 3.55 parts of sand, 0.57 parts of pumping agent, 0.14 parts of slump retaining agent, 0.28 parts of water reducing agent, and 25.72 parts of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com