Electrolyte composition of lead storage battery and lead storage battery using the same

A lead-acid battery and electrolyte technology, applied in the direction of lead-acid batteries, lead-acid battery construction, batteries, etc., can solve problems such as short life, electrolyte reduction, stratification, etc., to reduce complaint rate and claim costs, and improve stratification Phenomenon, the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

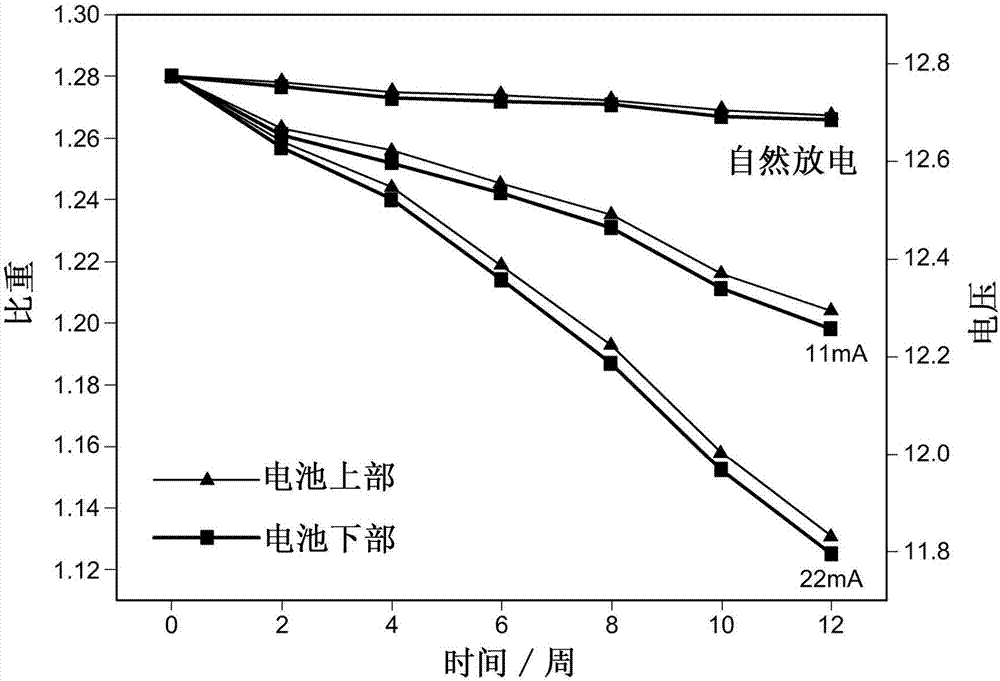

[0063] Experimental Example 1: Evaluation of Influence of Discharge Reaction on Stratification Phenomenon

[0064] In order to confirm the magnitude of the dark current during dark current discharge and the change in the specific gravity of the upper / lower part of the electrolyte of the lead acid battery over time, an existing lead acid battery was prepared, and then the experiment was carried out under the following experimental conditions. Specifically, dark current ① natural discharge (0mA), ② 11mA (condition for turning on (ON) the dark current cutoff device), and ③ 22mA (condition for turning off (OFF) the dark current cutoff device) in the upper part / Lower specific gravity. Also, the measured upper / lower specific gravity difference of the battery is shown graphically. image 3 , Figure 4 The results are shown.

[0065] image 3 It is a graph showing the change in specific gravity of the upper part / lower part of the electrolytic solution of the lead acid battery acc...

experiment example 2

[0068] Experimental Example 2: Evaluation of Influence of Charge / Discharge Reaction on Stratification Phenomenon

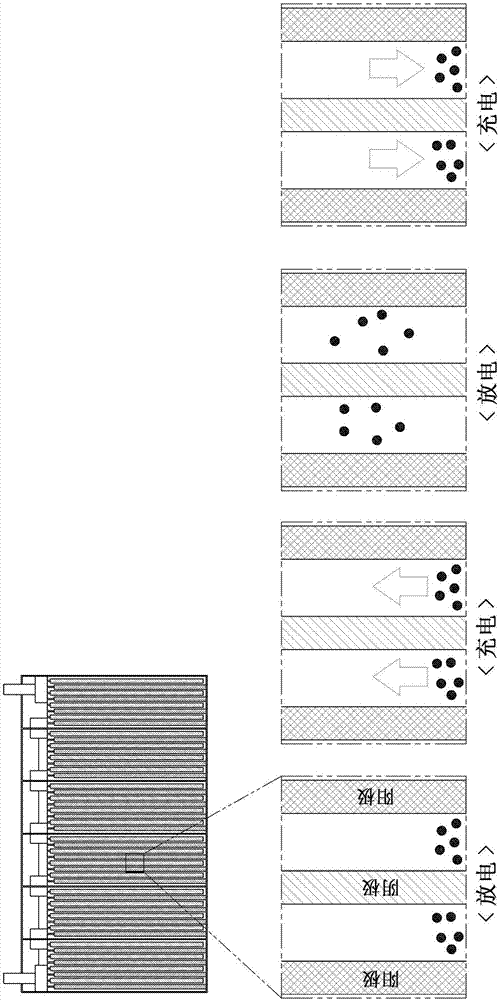

[0069] In order to evaluate the influence of the charge / discharge reaction of the lead-acid battery on the stratification phenomenon, the change in the specific gravity of the electrolytic solution at each stage of charge / discharge of the lead-acid battery was analyzed under the following experimental conditions. Specifically, the electrolyte solution of each stage of the existing lead-acid storage battery performing discharge (13.6A, 20hr)→storage (10hr)→charging (13.6A, 24hr)→storage (10hr)→discharge (13.6A, 20hr) was measured proportion. At this time, the lead-acid battery is at 13.6A: 4*I 20 (I 20 =3.4A, 68Ah base 20 time proportional discharge current) under the conditions. Figure 5 , Figure 6 The results are shown.

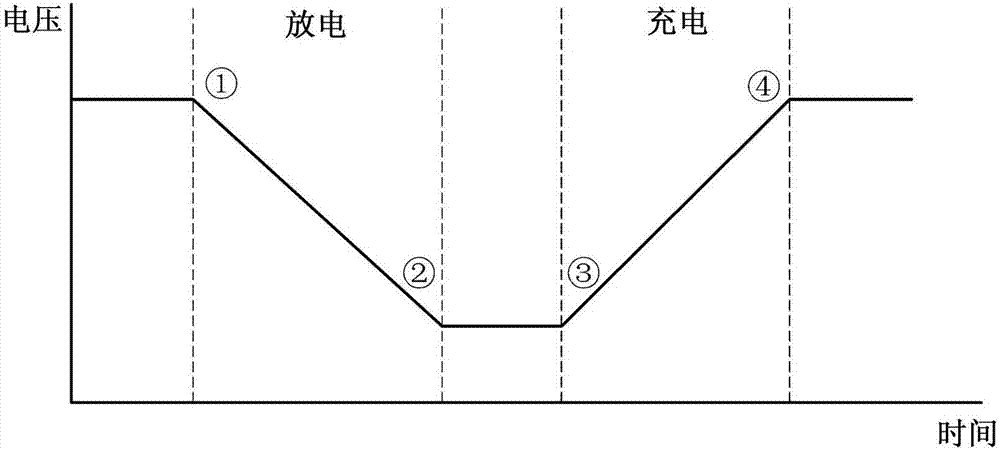

[0070] Figure 5 It is a graph which shows the voltage change with time after the lead-acid storage battery of the said experiment exam...

experiment example 3

[0073] Experimental example 3: Evaluation of the deviation of the upper / lower specific gravity of the electrolyte of the lead-acid battery based on the specific gravity of the dispersant and the content used

[0074] In order to perform evaluation (stratification progress index) of the electrolytic solution upper part / lower part specific gravity deviation (stratification phenomenon progress index) based on the specific gravity of a dispersant and the usage content of a lead acid battery, an electrolytic solution was produced by the following method. Specifically, the specific gravity and component ratio shown in the following Table 2 were injected|thrown-in, and the electrolytic solution for lead acid batteries was manufactured. Among them, as the dispersant, a spherical powder dispersant having an average particle size of 100 μm was used. A mixture of polypropylene and talc filler was used as dispersant.

[0075] Using the electrolyte solution produced as above, a lead stora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com