Ibuprofen splitting technology and purifying method based on splitting technology

A purification method and process technology, which is applied in the field of medicine, can solve problems such as complex processes and increased production costs, and achieve the effect of simple split steps, reduced split costs, and simple and environmentally friendly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

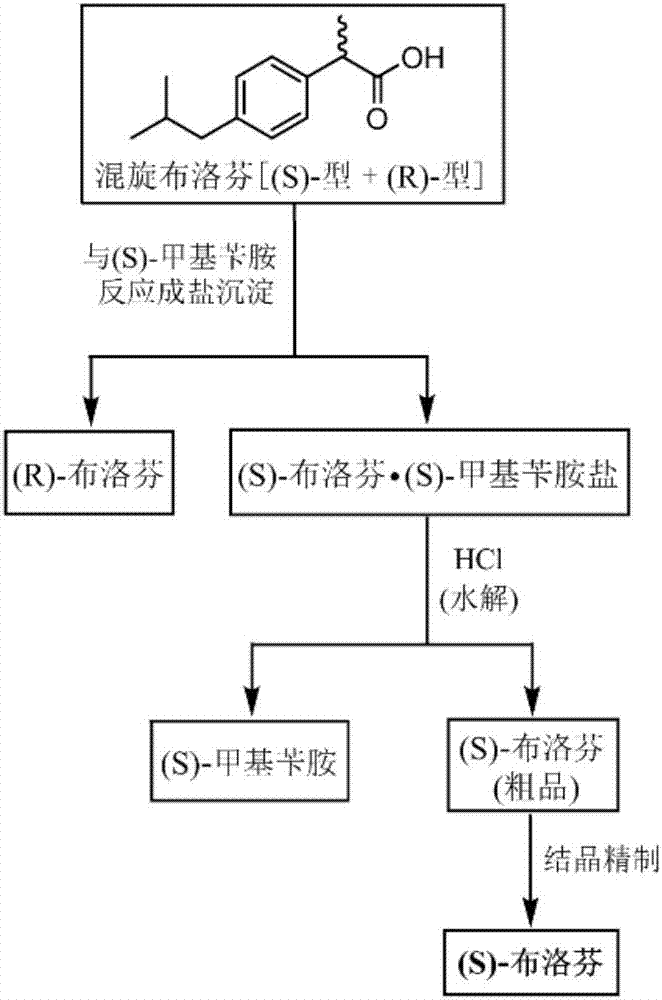

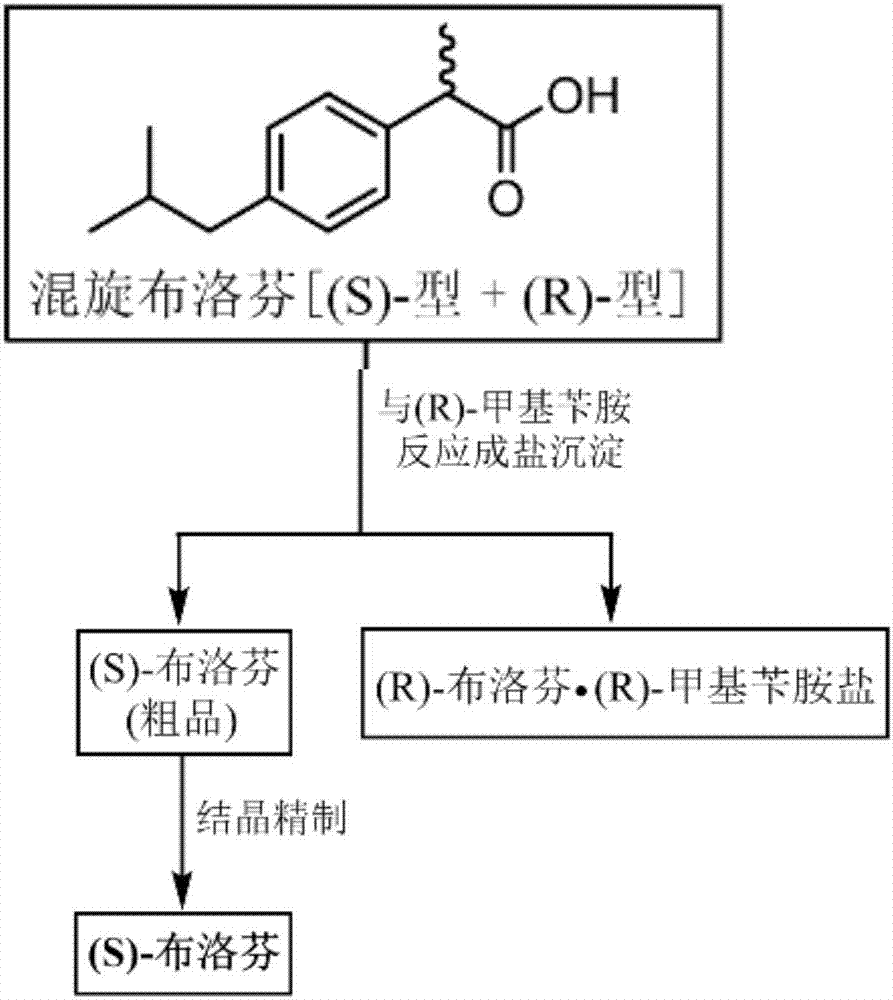

Method used

Image

Examples

Embodiment 1

[0053] A kind of ibuprofen splitting process, the steps are:

[0054] (1) under normal pressure and condensing condition, 10.3g swirl ibuprofen and ethanol (the feeding ratio of ethanol and swirl ibuprofen is 3ml / g) joins the reaction bottle that is equipped with constant pressure funnel and condensing tube After dissolving, it is heated to 55°C, and R-methylbenzylamine ethanol solution is added dropwise to form a suspension. The ratio of R-methylbenzylamine and dextrin ibuprofen is 0.55:1, wherein R-methylbenzylamine Both methylbenzylamine and dextrin ibuprofen are in moles, and the organic solution of R-methylbenzylamine adopts R-methylbenzylamine ethanol solution, and in the R-methylbenzylamine ethanol solution, R-methylbenzylamine The feed ratio of amine to ethanol is 1:2.5-3.5, wherein R-methylbenzylamine is measured in g, and ethanol is measured in ml;

[0055] (2) Stir the suspension obtained in step (1) for 1 h while maintaining the temperature of step (1);

[0056] ...

Embodiment 2

[0059] A kind of ibuprofen splitting process, the steps are:

[0060] (1) under normal pressure and condensing condition, 10.3g swirl ibuprofen and isopropanol (the feeding ratio of isopropanol and swirl ibuprofen is 3ml / g) join into the constant pressure funnel and condensate In the reaction bottle of tube, after dissolving, be heated to 82 ℃, drop R-methylbenzylamine isopropanol solution, form suspension, the feeding ratio of described R-methylbenzylamine and dextrin ibuprofen is 0.55: 1, wherein R-methylbenzylamine and dextrin ibuprofen are all in moles, and the R-methylbenzylamine organic solution adopts R-methylbenzylamine isopropanol solution, and the R-methylbenzylamine The feed ratio of R-methylbenzylamine and isopropanol in the isopropanol solution is 1:3.5, wherein R-methylbenzylamine is measured in g, and isopropanol is measured in ml;

[0061] (2) Stir the suspension obtained in step (1) for 1 h while maintaining the temperature of step (1);

[0062] (3) After st...

Embodiment 3

[0065] A kind of ibuprofen splitting process, the steps are:

[0066] (1) under normal pressure and condensing condition, 10.3g swirl ibuprofen and isopropanol (the feeding ratio of isopropanol and swirl ibuprofen is 10ml / g) join into the constant pressure funnel and condensate In the reaction bottle of tube, after dissolving, be heated to 82 ℃, dropwise add R-methylbenzylamine isopropanol solution, form suspension, the feeding ratio of described R-methylbenzylamine and dextrin ibuprofen is 0.65: 1, wherein R-methylbenzylamine and dextrin ibuprofen are all in moles, and the R-methylbenzylamine organic solution adopts R-methylbenzylamine isopropanol solution, and the R-methylbenzylamine The feed ratio of R-methylbenzylamine and isopropanol in the isopropanol solution is 1:2.5-3.5, wherein R-methylbenzylamine is in g and isopropanol is in ml;

[0067] (2) Stir the suspension obtained in step (1) for 1 h while maintaining the temperature of step (1);

[0068] (3) After the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com