Fuel cell-combined power supply system and energy management method

A fuel cell and power supply system technology, applied in the direction of DC power supply parallel operation, circuit devices, DC network circuit devices, etc., can solve the problems of complex derivation and calculation process, high requirements for real-time computing and processing capabilities of hardware equipment, unfavorable smooth and stable control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

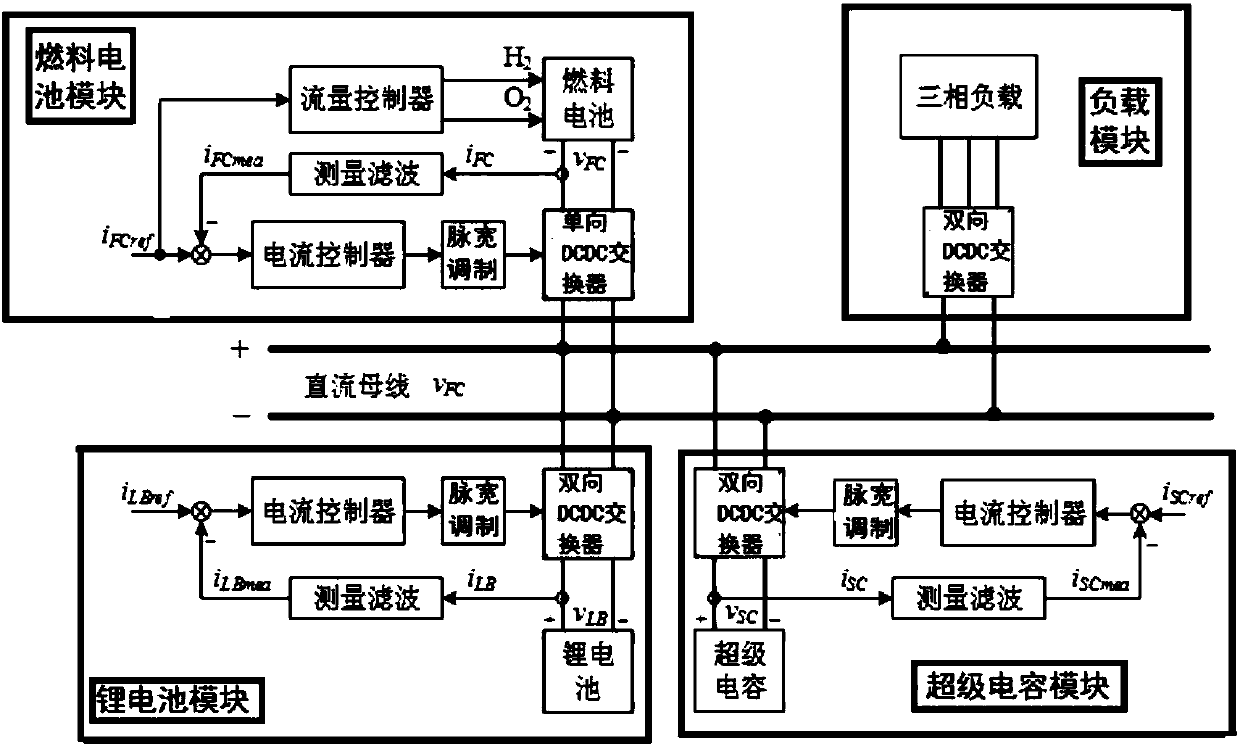

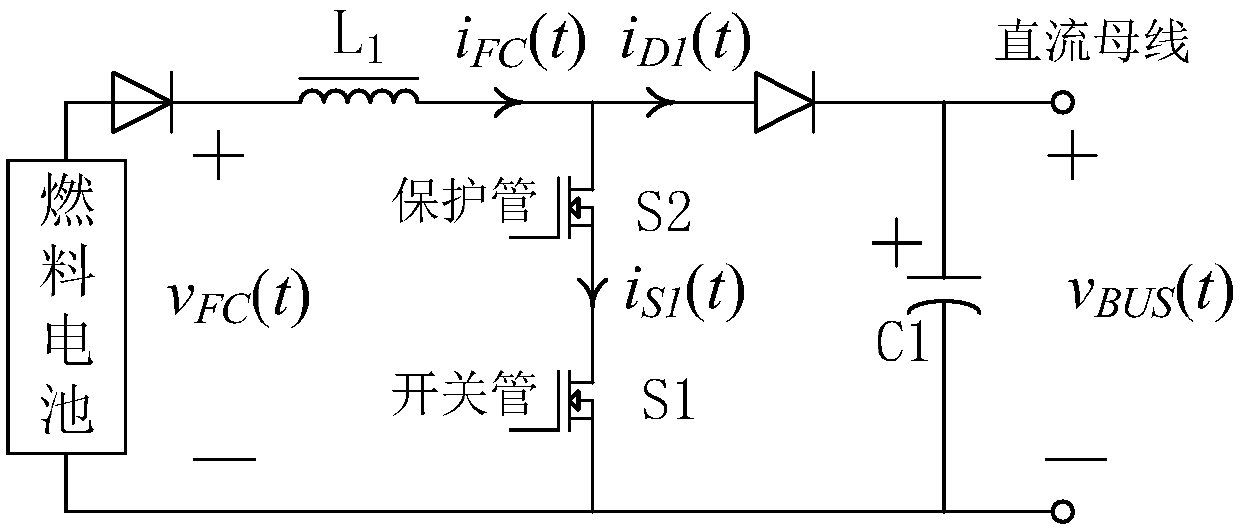

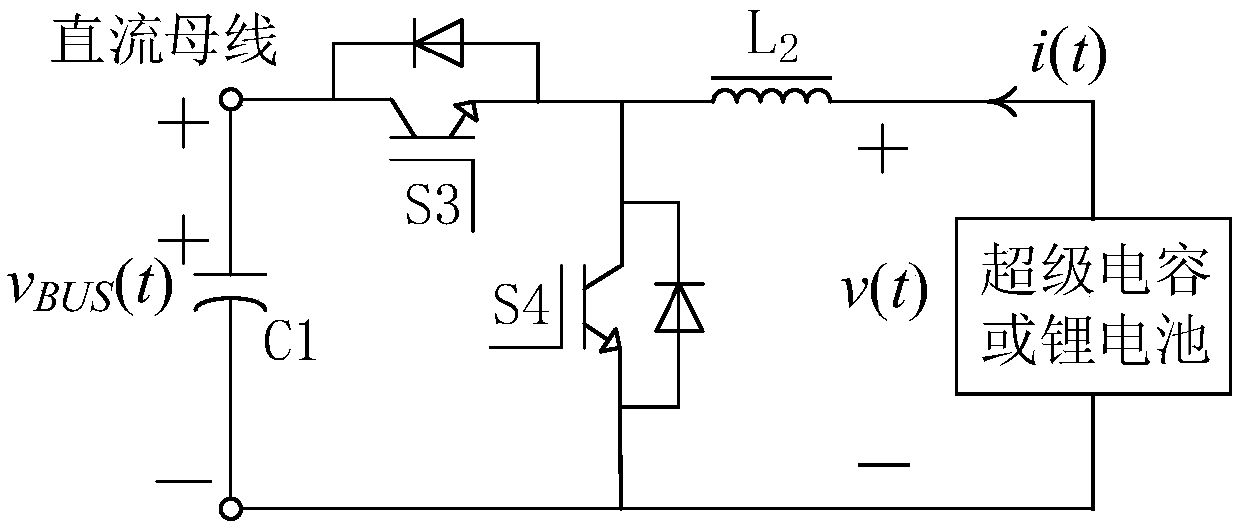

[0030] Such as Figure 1 to Figure 12As shown, a fuel cell combined power supply system proposed by the present invention includes a fuel cell module, a lithium battery module, a supercapacitor module, a DC bus, a load module, a DC bus voltage control loop, a supercapacitor voltage control loop, and a lithium battery voltage control loop. , lithium battery charging control loop, simulation software, energy management system; fuel cell module includes: fuel cell, unidirectional DCDC converter, flow controller, measurement filter, pulse width modulator, current controller, negative feedback input terminal, One end of the unidirectional DCDC converter is connected to the positive and negative poles of the DC bus, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com