Emergency core cooling system for nuclear power plant

An emergency core and cooling system technology, applied in reactors, nuclear power generation, cooling devices, etc., can solve problems such as uneven flow distribution at injection points, leakage of penetrating parts, complex system configuration, etc., to eliminate the increase of penetrating parts and increase safety The effect of injecting flow rate and simplifying system configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

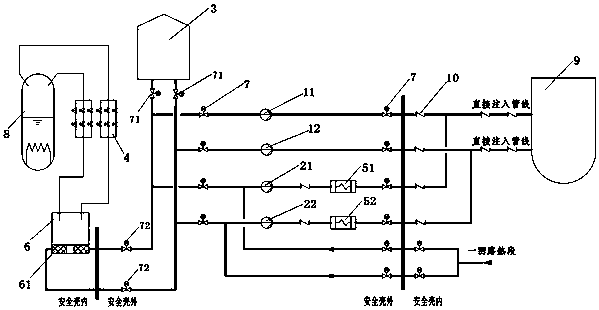

[0038] This embodiment is an emergency core cooling system of a nuclear power plant, and its system structure schematic diagram is as follows figure 2 As shown, compared with the prior art system, the improved emergency core cooling system still adopts safe injection methods under three pressure levels of high, medium and low, but this embodiment greatly simplifies the system configuration. Specifically, the nuclear power plant emergency core cooling system in this embodiment includes a high-pressure safety injection pump, a low-pressure safety injection pump, a safety injection water tank 3, an automatic pressure relief system (ADS) 4, a pressurizer 8, a pressure vessel 9 and a direct Injection pipeline, waste heat discharge heat exchanger 5 and containment suppression tank 6, wherein the automatic pressure relief system (ADS) 4, containment suppression tank 6, pressurizer 8, pressure vessel 9 and direct injection pipeline are set Inside the containment, the high-pressure sa...

Embodiment 2

[0052] Embodiment 2 is based on Embodiment 1 to further optimize the design of the low-pressure installation pump and high-pressure safety injection pump and the quantity and arrangement of waste heat discharge heat exchanger 5, but the low-pressure installation pump, high-pressure safety injection pump and waste heat The discharge heat exchanger 5 is not limited to the design of this embodiment.

[0053] In this embodiment, the first high-pressure safety injection pump 11, the second high-pressure safety injection pump 12, the first low-pressure safety injection pump 21, the second low-pressure safety injection pump 22, the safety injection water tank 3, the automatic pressure relief system 4, The connection relationship between the first waste heat discharge heat exchanger 5, the second waste heat discharge heat exchanger 5, the containment suppression pool 6, the pressurizer 8 and the pressure vessel 9 is as follows: figure 2 As shown, specifically, the low-pressure safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com