Jet device, spray head assembly and concrete jet vehicle

A technology of injection device and assembly, which is used in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of short service life and easy bursting of nozzle joints, avoid explosion, ensure mixing, and avoid nozzle explosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

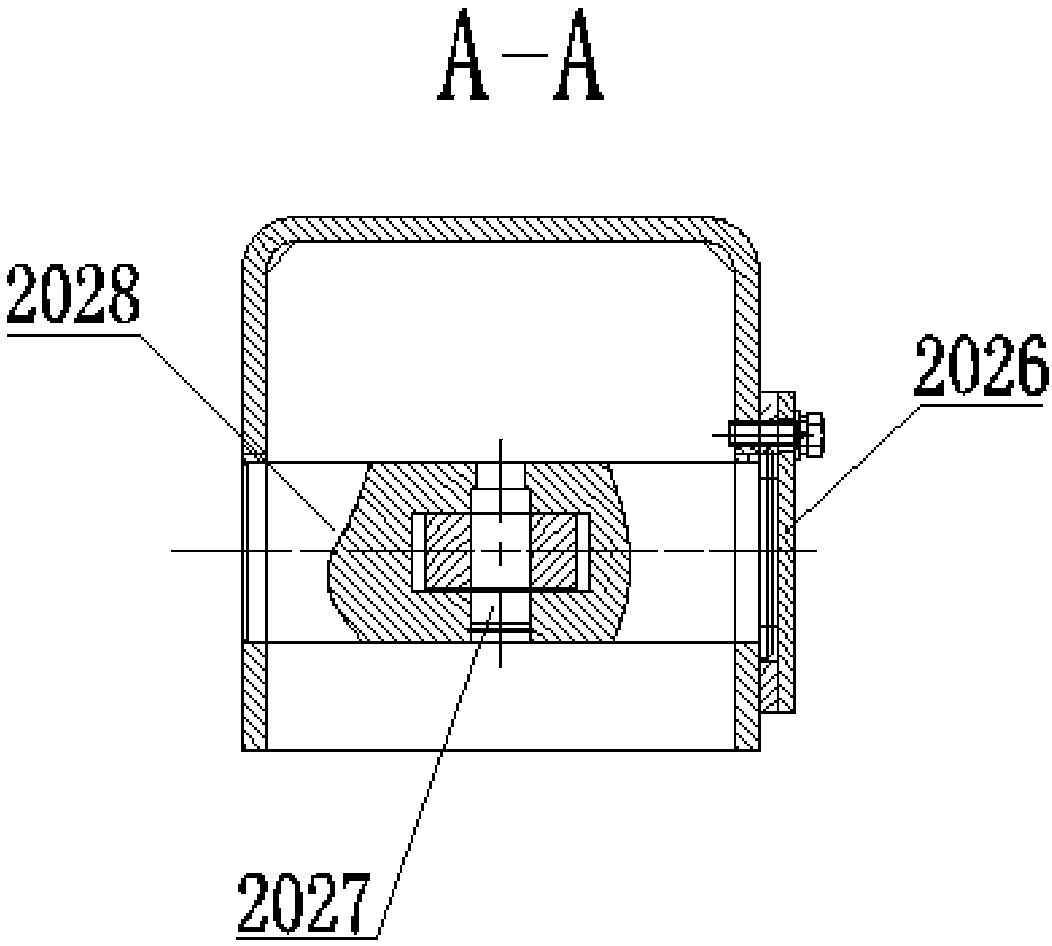

[0042] figure 1 Schematic diagram of the structure of the injection device provided for the embodiment of the present invention; figure 2 A cross-sectional view of A-A of the injection device provided for the embodiment of the present invention; image 3 B-B sectional view of the injection device provided by the embodiment of the present invention.

[0043] like Figure 1-3 As shown, the injection device provided in this embodiment includes: a nozzle 101 and a mixing device 102 connected to the nozzle 101, and a clamping device 108 for clamping the nozzle 101 is provided at the connection between the mixing device 102 and the nozzle 101; the mixing device 102 includes The casing 1021 and the mixer 1024, the cavity 1022 is formed between the casing 1021 and the mixer 1024; the ventilation pipe 1023 is connected to the casing 1021; the problem of the nozzle 101 bursting is avoided; the construction interval is reduced, and the life of the nozzle 101 is improved And greatly r...

Embodiment 2

[0052] Figure 4 Schematic diagram of the structure of the nozzle assembly provided by the embodiment of the present invention; Figure 5 Schematic diagram of the structure of the driving device of the spray head assembly provided by the embodiment of the present invention.

[0053] like Figure 4-5 As shown, the spray head assembly provided in this embodiment includes: a driving device and the above-mentioned spraying device 100 ; the driving device is connected to the outer wall of the mixing device 102 on the spraying device 100 .

[0054] Specifically, the driving device includes a swinging device 201 and a brushing device 202; the brushing device 202 includes a first hanger 2021 and a second hanger 2022, the first hanger 2021 is connected to the swinging device 201, and the second hanger 2022 is connected by The parts are connected to the outer wall of the mixing device 102.

[0055] Further, the brushing device 202 also includes a first output mechanism 2024 installed...

Embodiment 3

[0065] The concrete spraying vehicle provided in this embodiment includes: the above-mentioned spray head assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com