Thin skin milling device and method for milling by utilizing device

A skin and milling technology is applied in the field of thin skin milling and cutting devices to achieve the effects of improving work efficiency, reducing use time, and reducing clamping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

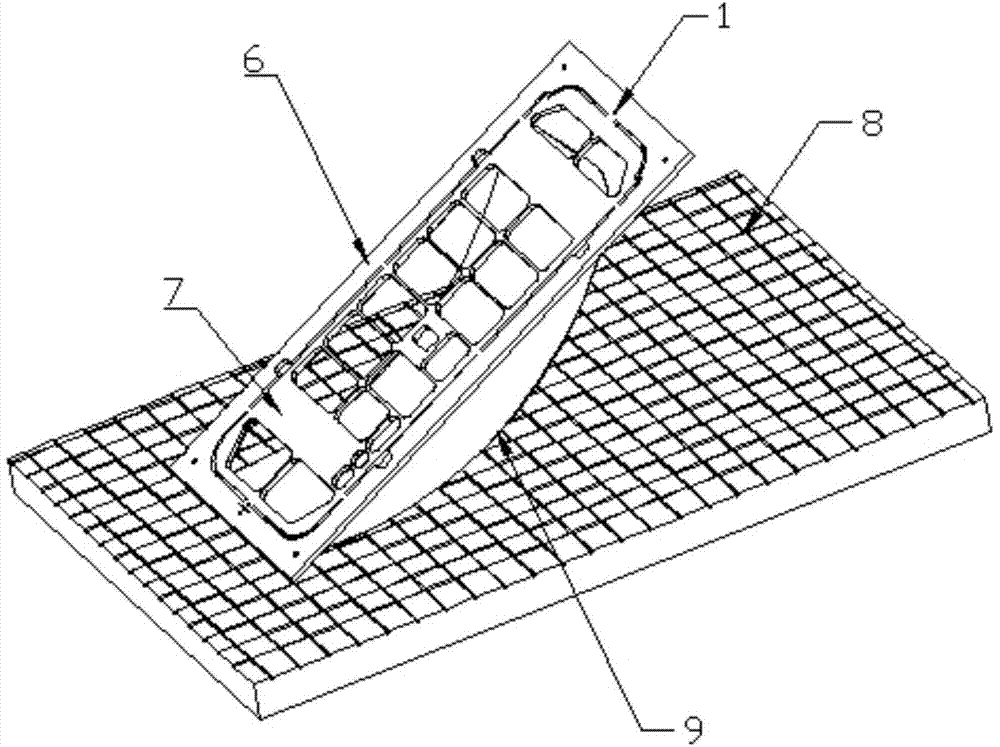

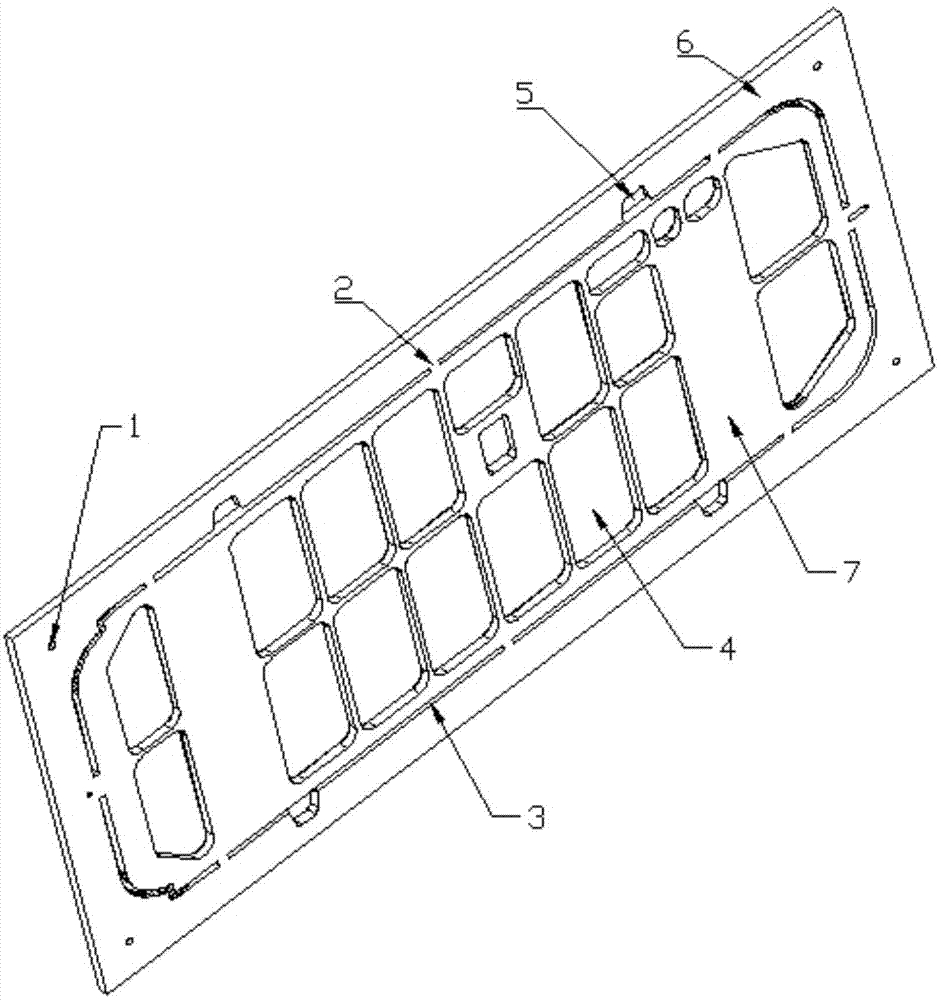

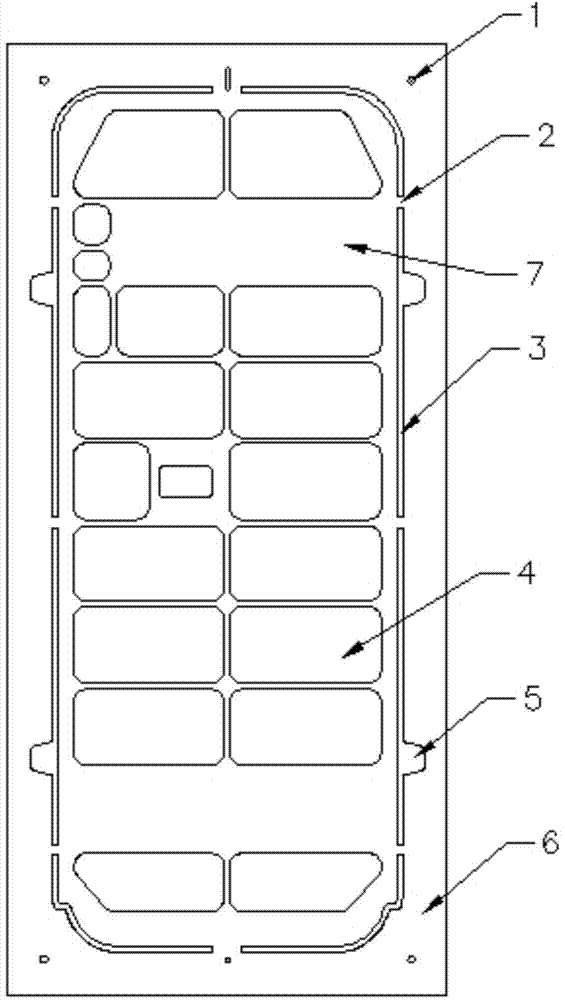

[0036] Such as Figure 1-3 A kind of thin skin milling device shown, comprises vacuum platform 8, Figure 2-3 Profile hold down fixture shown, thin skin 9. The thin skin 9 is placed on the vacuum platform 8, and the profiling clamp is placed on the thin skin 9. The surface area of the vacuum platform 8 is larger than that of the profiling clamp, and the surface area of the profiling clamp is larger than that of the thin skin 9. The surface area of the profiling clamp is a rectangular thick aluminum plate. The surface plane of the thick aluminum plate near the edge has a cut-off groove 3 that matches the outer contour of the thin skin 9. The surface of the thick aluminum plate has a depression with the thin skin 9. For the sunken milling area 4 that matches the area, the profiling clamp has an outer contour pressing area 6 in the area outside the cutting 3, and an inner pressing area 7 in the area inside the cutting groove 3.

[0037] The surface of the vacuum platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com