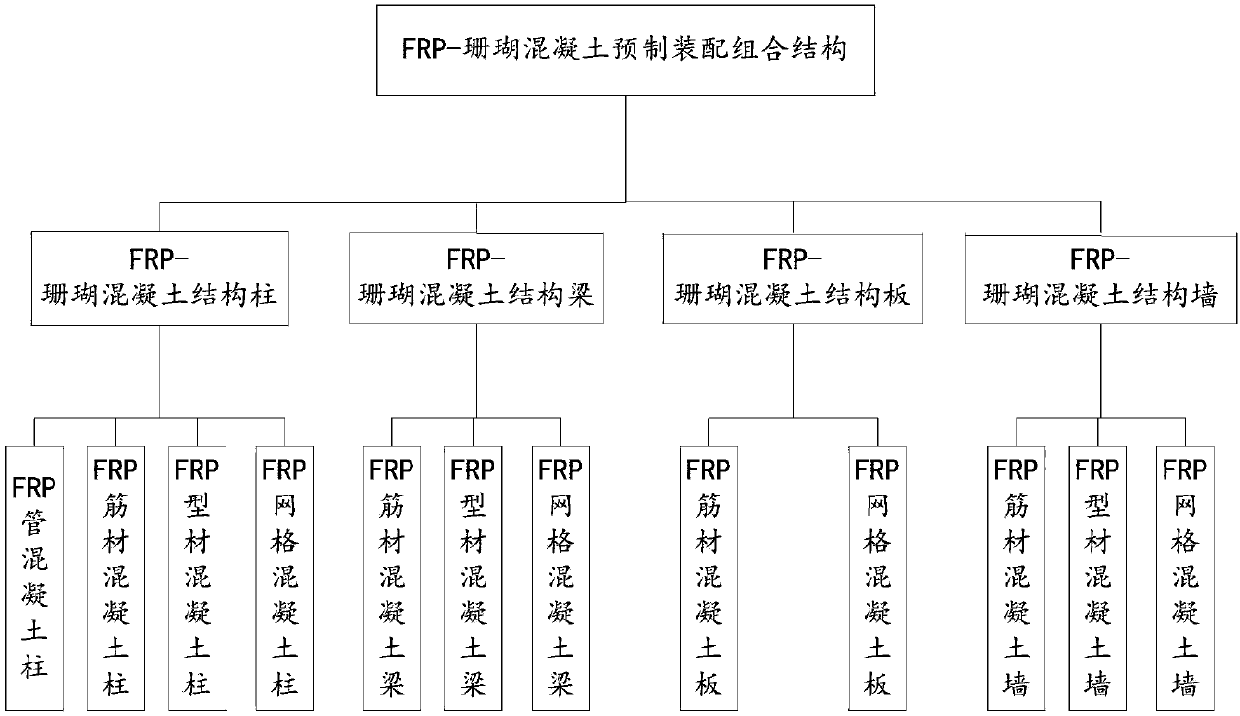

FRP-concrete prefabricated assembly combined structure

A technology of concrete structure and concrete structural column, which is applied in the field of FRP-concrete prefabricated assembly structure, can solve the problems of difficult sea transportation of raw materials, poor structural durability, economic burden loss, etc., so as to facilitate local materials, reduce construction costs, and save projects The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

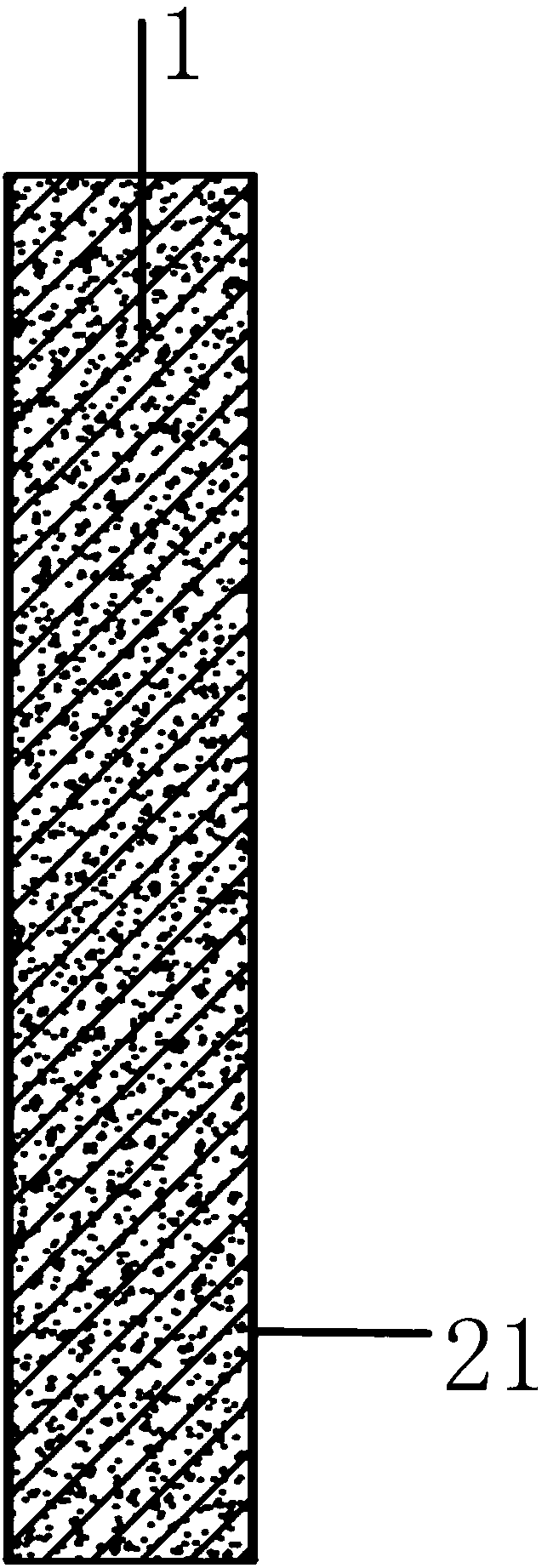

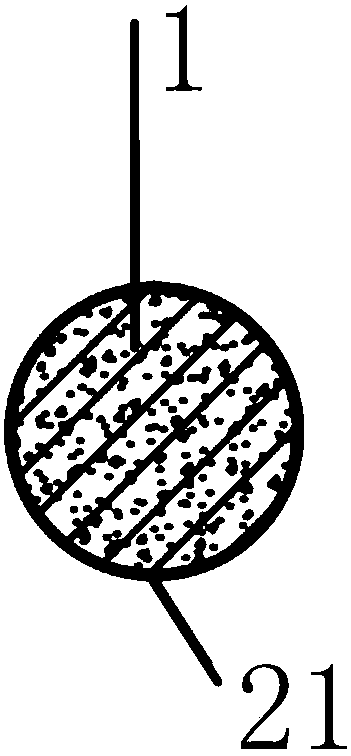

[0051] Please refer to the attached figure 1 , 2 The present invention provides an FRP pipe concrete column, and the coral concrete 1 is poured into the FRP pipe 21 to form the FRP pipe concrete column.

Embodiment 2

[0053] Please refer to the attached image 3 , 4 A kind of FRP reinforced concrete column is provided for the present invention, and FRP reinforced material 22 is arranged around, and FRP grid 23 is fixed on the FRP reinforced material 22 by FRP stirrup equidistant, constitutes three-dimensional structure, and three-dimensional structure is placed on the mold Among them, coral concrete 1 is poured to form FRP reinforced concrete columns.

Embodiment 3

[0055] Please refer to the attached Figure 5 , 6 The present invention provides a concrete column with FRP profiles. The FRP profile 24 is placed in a mold, and the coral concrete 1 is poured to form the FRP profile concrete column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com