POSS modified nanofiber membrane and preparation method and application thereof

A nanofiber membrane, nanofiber technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of low reactivity, poor fiber membrane toughness, low mechanical strength, etc., to improve thermal stability and mechanical strength. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

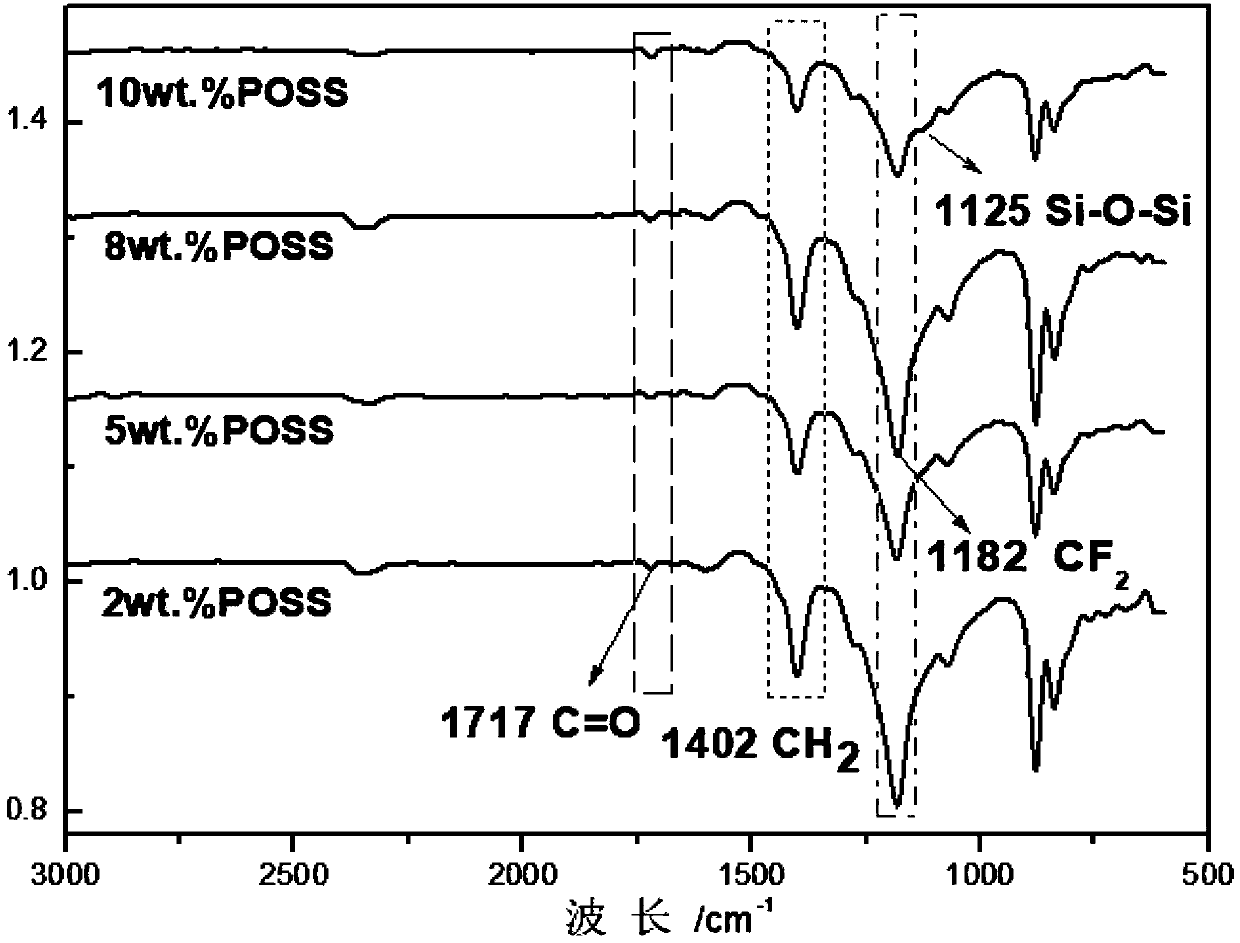

Method used

Image

Examples

Embodiment 1

[0033] (1) In a 25ml serum bottle, use a graduated cylinder to measure 4ml N,N-dimethylacetamide (DMAc) and 6ml acetone (ACE) to prepare a mixed solvent, and weigh the mass ratio according to the solution mass concentration of 18wt.%. 5:1 PVDF 1.31g and PMMA 0.26g, then pour the weighed PVDF and PMMA into the mixed solvent, put it into the magnet and heat it to 50°C with a heatable magnetic stirrer to stir and dissolve, fully dissolve and cool to room temperature Stirring was continued for 18 hours to obtain a homogeneous polymer electrospinning solution.

[0034] (2) According to the total mass of PVDF and PMMA, determine the POSS functional monomer mass concentration 2wt.%, take by weighing respectively 15.7 mg of MA-POSS and OAPS with a mass ratio of 1:1, measure 10 ml of dichloromethane (DCM ) as a solvent, dissolve the weighed MA-POSS and OAPS functional monomers in DCM, put them into the magnetron and stir and dissolve at room temperature with a magnetic stirrer for 3h t...

Embodiment 2

[0037] (1) In a 25ml serum bottle, use a graduated cylinder to measure 4ml N,N-dimethylacetamide (DMAc) and 6ml acetone (ACE) to prepare a mixed solvent, and weigh the mass ratio according to the solution mass concentration of 18wt.%. 5:1 PVDF 1.31g and PMMA 0.26g, then pour the weighed PVDF and PMMA into the mixed solvent, put it into the magnet and heat it to 50°C with a heatable magnetic stirrer to stir and dissolve, fully dissolve and cool to room temperature Stirring was continued for 18 hours to obtain a homogeneous polymer electrospinning solution.

[0038] (2) According to the total mass of PVDF and PMMA, determine POSS functional monomer mass concentration 5wt.%, take by weighing respectively MA-POSS 19.62mg and OAPS 58.88mg that mass ratio is 1:3, measure the dichloromethane of 10ml ( DCM) was used as a solvent, and the weighed MA-POSS and OAPS functional monomers were dissolved in DCM, put into a magnet and stirred and dissolved at room temperature with a magnetic s...

Embodiment 3

[0041] (1) In a 25ml serum bottle, use a graduated cylinder to measure 4ml N,N-dimethylacetamide (DMAc) and 6ml acetone (ACE) to prepare a mixed solvent, and weigh the mass ratio according to the solution mass concentration of 18wt.%. 3.2:1 PVDF 1.20g and PMMA 0.37g, then pour the weighed PVDF and PMMA into the mixed solvent, put it into the magnet and heat it to 50°C with a heatable magnetic stirrer to stir and dissolve, fully dissolve and cool to room temperature Stirring was continued for 18 hours to obtain a homogeneous polymer electrospinning solution.

[0042] (2) According to the total mass of PVDF and PMMA, determine POSS functional monomer mass concentration 8wt.%, take by weighing MA-POSS 41.87mg and OAPS 83.73mg that mass ratio is 1:2 respectively, measure the dichloromethane ( DCM) was used as a solvent, and the weighed MA-POSS and OAPS functional monomers were dissolved in DCM, put into a magnet and stirred and dissolved at room temperature with a magnetic stirrer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com