All-component utilization sugar cane-to-sugar system and treatment method thereof

A full-component, sugarcane technology, applied in the direction of purification, sucrose production and application using physical methods, can solve the problems of using a large number of chemicals, secondary pollution, etc., and achieve the effect of reducing investment and operating costs and avoiding accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

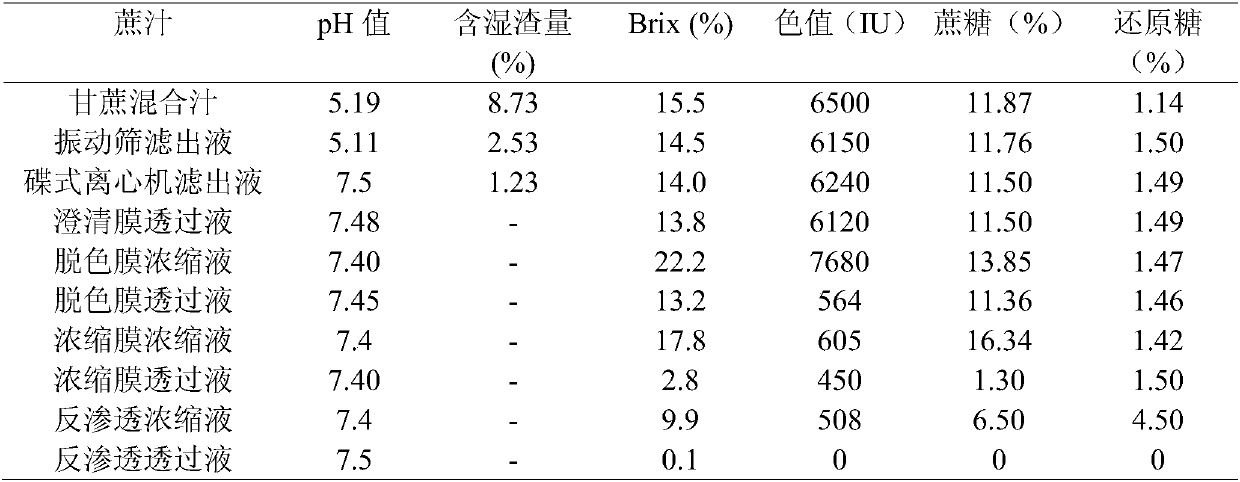

Embodiment 1

[0091] The present embodiment provides a kind of whole component utilization sugar cane sugar making system, such as figure 1 As shown, the system includes a pretreatment unit, a multistage membrane filtration unit and a concentrate treatment unit;

[0092] The pretreatment unit includes a vibrating screen 1 and a solid-liquid separation device 2, the liquid outlet of the vibrating screen 1 is connected to the feed port of the solid-liquid separation device 2; the vibrating screen is a two-stage vibrating screen, the first stage The screen mesh precision is 40 mesh, and the second stage screen mesh precision is 120 mesh; the solid-liquid separation device 2 is a scraper type self-cleaning filter;

[0093] The multi-stage membrane filtration unit includes a clarification membrane 3, a decolorization membrane 4, a concentration membrane 5 and a reverse osmosis membrane 6, the liquid outlet of the solid-liquid separation device 2 is connected to the feed port of the clarification...

Embodiment 2

[0104] This embodiment provides a sugar cane sugar production system utilizing all components, the system includes a pretreatment unit, a multi-stage membrane filtration unit and a concentrate treatment unit;

[0105] The pretreatment unit includes a vibrating screen 1 and a solid-liquid separation device 2, the liquid outlet of the vibrating screen 1 is connected to the feed port of the solid-liquid separation device 2; the vibrating screen is a two-stage vibrating screen, the first stage The screen mesh precision is 60 mesh, and the second stage screen mesh precision is 150 mesh; the solid-liquid separation device 2 is a scraper type self-cleaning filter;

[0106] The multi-stage membrane filtration unit includes a clarification membrane 3, a decolorization membrane 4, a concentration membrane 5 and a reverse osmosis membrane 6, the liquid outlet of the solid-liquid separation device 2 is connected to the feed port of the clarification membrane 3, and the clarification membra...

Embodiment 3

[0117]This embodiment provides a sugarcane sugar production system utilizing all components. The system structure refers to Embodiment 1, the difference is that: the first-stage sieve has a precision of 20 mesh, and the second-stage sieve has a precision of 100 mesh; The molecular weight cut-off of the clarification membrane 3 is 30000Da, the decolorization membrane 4 is a polyamide roll-type ultrafiltration membrane module, and the molecular weight cut-off is 1000Da, and the concentrated membrane 5 is a polyamide roll-type membrane module, and the molecular weight cut-off is 150Da. The reverse osmosis membrane 6 module is a polyamide roll-type membrane module, and the standard desalination rate is 99.3%.

[0118] The treatment method of the sugarcane sugar production system refers to the method in Example 1, the difference is: in step (1), the pH is adjusted to 6.8 and heated to 55 ° C; in step (2), the clarification membrane 3 is clarified at 0.5 MPa, The filtration temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com