Clostridium butyricum agent with strong butyric acid resistance and stress resistance and application thereof

A technology of Clostridium butyricum and bacteria agent, applied in the field of microbial fermentation, can solve the problems affecting the application of Clostridium butyricum and low fermentation level, achieve strong application value, improve fermentation level, and increase daily weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The mutagenesis cultivation of embodiment 1, LXKJYB-1

[0038] (1) Suspension preparation:

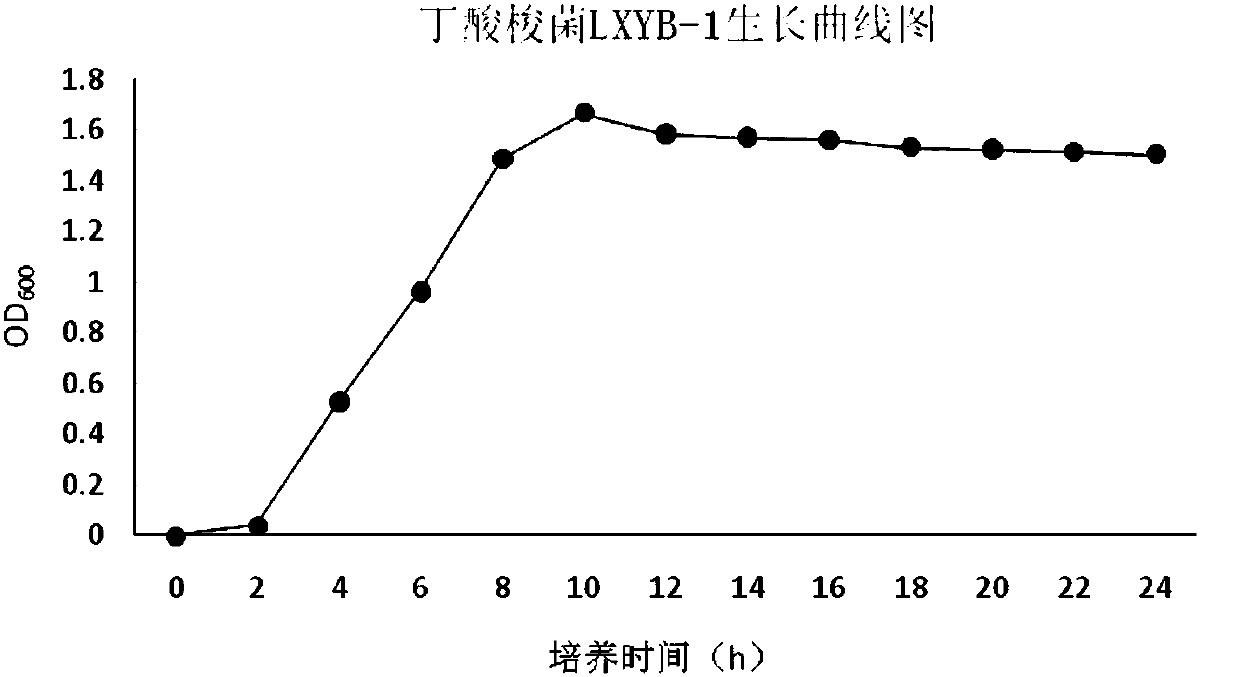

[0039] Activate the Clostridium butyricum LXKJ-1 strain preserved in the glycerol tube, pick a single colony and inoculate it in the RCM liquid medium, and cultivate it for 8-10 hours according to the growth curve, that is, collect the bacterial liquid in the logarithmic phase for centrifugation, and collect Bacteria were washed two to three times with normal saline, and the mutagenesis suspension was prepared for mutagenesis. The concentration of bacteria in the mutagenesis solution was 2×10 6 cfu / ml. Growth curve see figure 1 .

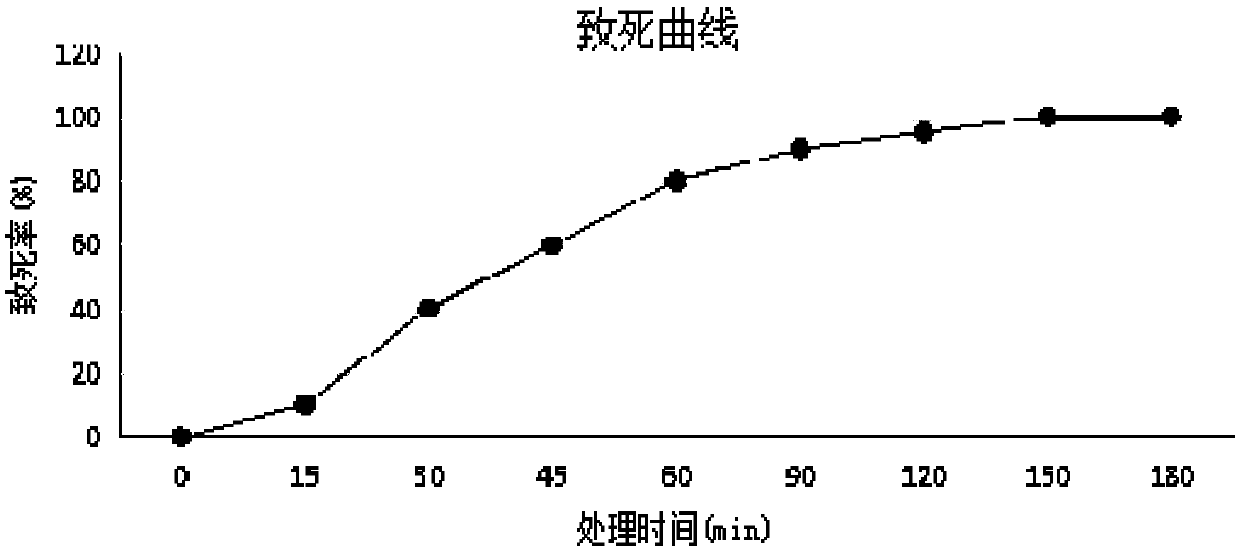

[0040] (2) Make a lethal curve

[0041] The dose or time of mutagenesis treatment not only affects the lethal rate, but also can significantly affect the mutation efficiency. Effective screening in an appropriate range of mutation efficiency is the key to strain selection. In this study, the starting strains were first subjected to plasma jet treat...

Embodiment 2

[0058] Embodiment 2, the impact of different fermentation media on the fermentation level of butyric acid-resistant high-yield strain LXKJYB-1

[0059] Put the LXKJYB-1 frozen in the glycerol tube into the activation medium, and culture it statically at 37°C for 18 hours; the activated Clostridium butyricum LXKJYB-1 was inoculated into the seed medium with an inoculation amount of 5%, and anaerobically cultured at 37°C. Oxygen cultivation for 24 hours to obtain seed solution.

[0060] Fermentation medium 1: 2% ammonium sulfate, 2% corn flour, 2% yeast extract, 1% urea, 0.5% dipotassium hydrogen phosphate, pH 6.5-7.0, 0.5% calcium carbonate; dissolved in deionized water, stirred with a glass rod Mix evenly, sterilize after subpackaging, and sterilize at 121°C for 20 minutes;

[0061] Fermentation medium 2: 4% ammonium sulfate, 4% corn flour, 4% yeast extract, 2% urea, 1.5% dipotassium hydrogen phosphate, pH 6.5-7.0, 0.7% calcium carbonate; dissolved in deionized water, stirred...

Embodiment 3

[0067] Embodiment 3, the cultivation of Clostridium butyricum (Clostridium butyricum) LXKJYB-1

[0068] (1) Activation and seed cultivation

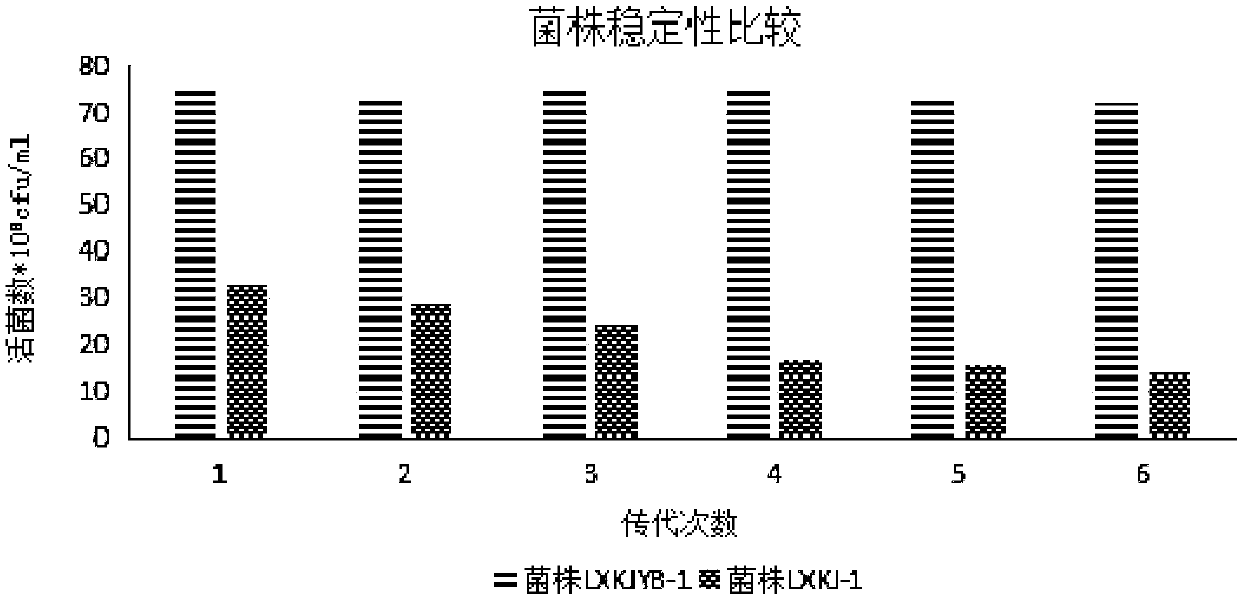

[0069] The LXKJYB-1 and LXKJ-1 strains frozen in glycerol tubes were respectively connected to the activation medium, and incubated anaerobically at 37°C for 18 hours; the activated Clostridium butyricum LXKJYB-1 and LXKJ-1 were respectively inoculated into the seed culture base, the inoculum size was 5%, and anaerobic culture was carried out at 37°C for 24 hours to obtain the seed solution.

[0070] (2) Primary seed cultivation

[0071] Inoculate the LXKJYB-1 and LXKJ-1 seed liquids activated in step (1) into the primary seed medium at 5% inoculum, anaerobically, at 37°C, and culture for 12 hours to amplify to obtain the primary seed liquid. Complete the comparison between the number of viable bacteria and the number of spores, as shown in Table 4.

[0072] (3) Secondary seed cultivation

[0073] Insert the primary seed liquid of Cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com