Method for preparing nano-micron autolysis temporary plugging diverter

A nano-micron, diverting agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as permanent formation blockage, tackifier polymer residues, and difficult recovery of formation permeability damage, etc. The effect of formation permeability recovery, simple preparation method and good plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

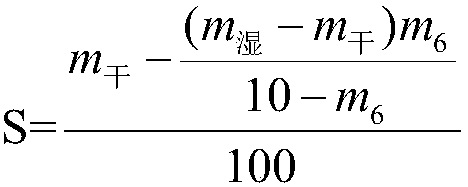

[0019] The preparation method of nano-micron-scale self-dissolving temporary plugging diversion agent for acidification of the present invention comprises the following steps:

[0020] (1) At room temperature, measure a certain amount of water and add an iron ion stabilizer, a clay stabilizer, a drainage aid, and a high-temperature corrosion inhibitor to it and stir to obtain a mixed solution I;

[0021] (2) Continue to add dispersant to mixed solution I and stir, then add suspending agent and sodium chloride and stir for 3-10min to obtain mixed solution II;

[0022] (3) Measure concentrated hydrochloric acid, slowly add in mixed solution II and constantly stir 10-30min, obtain the suspension that separates out to have sodium chloride particle;

[0023] The proportions of the above components are: 0.5-1.5 parts by mass of iron ion stabilizer, 0.5-1.5 parts by mass of clay stabilizer, 0.5-1.5 parts by mass of drainage aid, 0.5-1.5 parts by mass of high temperature Corrosion in...

Embodiment

[0034] This embodiment provides 1-4 examples of soluble salt particles self-turning temporary plugging diversion acidification fluid, which is prepared by the following steps:

[0035] At room temperature, add water first, then add iron ion stabilizer, clay stabilizer, drainage aid, high temperature corrosion inhibitor and stir, then add dispersant, suspending agent and sodium chloride in sequence, and stir for 3 to 10 minutes. When it is completely dissolved, measure concentrated hydrochloric acid and add it for 10-30 minutes while stirring to obtain a suspension with precipitated sodium chloride particles. Wherein, the amount of sodium chloride, concentrated hydrochloric acid and various additives is shown in Table 1 below.

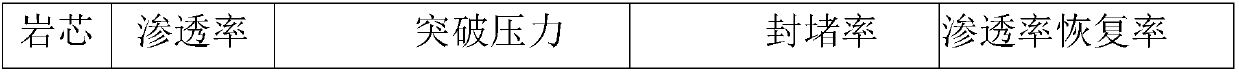

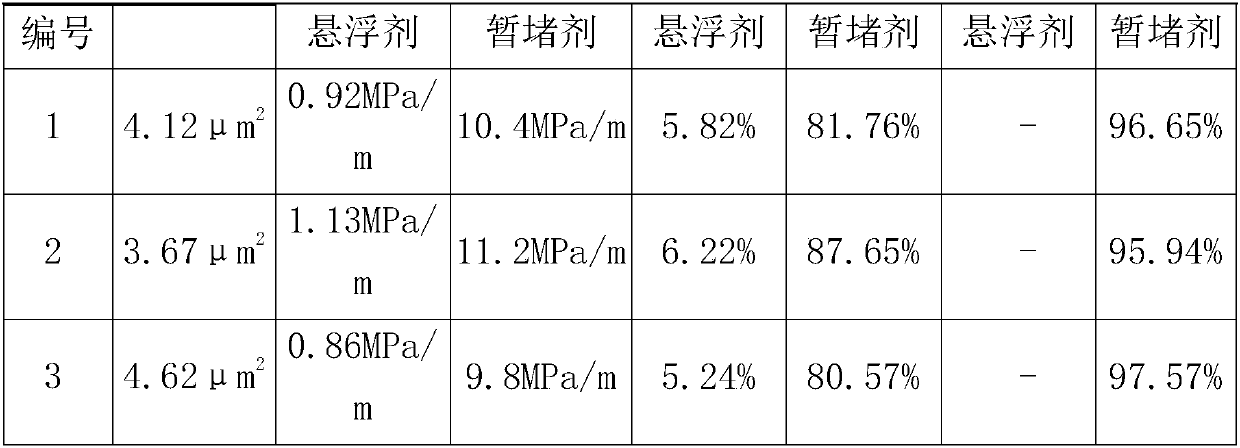

[0036] Table 1 1 to 4 cases of sodium chloride, concentrated hydrochloric acid and the dosage of various additives

[0037] substance

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com