Preparation method of coumarins polymer semiconductor laser material

A technology of coumarins and laser materials, applied in the structure of the active region, etc., can solve the problems that plague the development of organic lasers and the difficulty of realizing organic lasers, and achieve excellent thermal stability, low preparation costs, and simple and controllable synthesis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of coumarin polymer semiconductor laser material comprises the following steps:

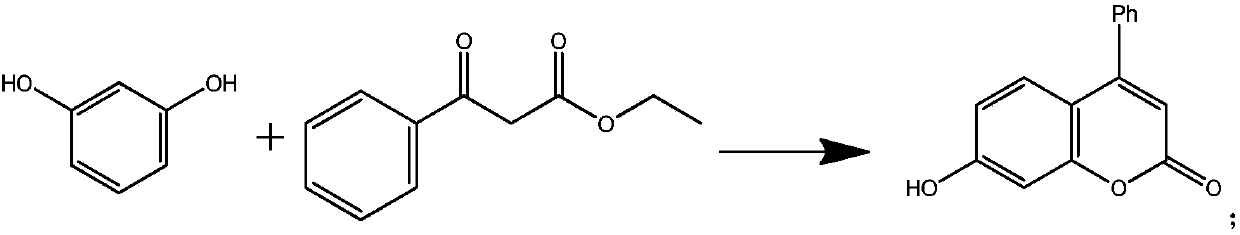

[0028] (1) Preparation of 4-phenyl-7-hydroxycoumarin: add 40.0mmol resorcinol, 60.0mmol ethyl benzoylacetate and 4.0mmol sodium bisulfate monohydrate in the round bottom flask, mix well, Place in a microwave chemical reactor, install a reflux device, and heat intermittently under the condition of a power of 400W. TLC monitors the reaction process. After heating for 8 minutes, the resorcinol disappears, and the microwave heating is stopped. After cooling, add 80 mL of ice water to the reaction flask, stir, and disperse with ultrasonic waves, a large amount of blocky solids are precipitated, and the water is removed by suction filtration, and then recrystallized with 95% ethanol to obtain 7.08 g of dark green solids, with a yield of 70.9%.

[0029] MS (m / z): 238.2 (M+, 92.1%), 210.1 (100%), 181.2 (34.2%), 152.1 (26.3%), 76.1 (9.2%). R f (0.55, ethyl acetate:petroleum ether=...

Embodiment 2

[0040] The preparation of coumarin polymer semiconductor laser material comprises the following steps:

[0041] (1) Preparation of 4-phenyl-7-hydroxycoumarin: In the presence of sodium bisulfate monohydrate, resorcinol and ethyl benzoyl acetate were refluxed to obtain 4-phenyl-7-hydroxy Coumarin; wherein, the molar ratio of sodium bisulfate monohydrate, resorcinol and ethyl benzoylacetate is 0.15:1:1.5, and the reaction time is 15min;

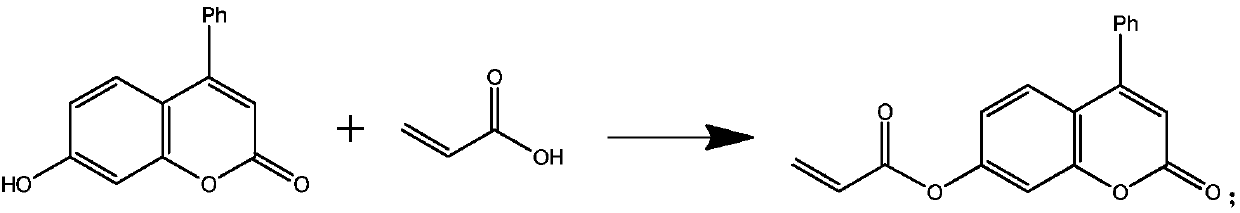

[0042] (2) Preparation of acrylic acid-4-phenyl-7-hydroxycoumarin ester: in the presence of hydroquinone, 10 mL of acrylic acid and dichloromethylene chloride react to obtain acryloyl chloride; in the presence of triethylamine, 4- Phenyl-7-hydroxycoumarin reacts with acryloyl chloride to obtain acrylate-4-phenyl-7-hydroxycoumarin ester; wherein, in the preparation reaction of acryloyl chloride, the amount ratio of acrylic acid and dichlorohydrin is 50mmol : 10mL, the reaction temperature is 40°C, and the reaction time is 2h; in the preparation...

Embodiment 3

[0046] The preparation of coumarin polymer semiconductor laser material comprises the following steps:

[0047] (1) Preparation of 4-phenyl-7-hydroxycoumarin: In the presence of sodium bisulfate monohydrate, resorcinol and ethyl benzoyl acetate were refluxed to obtain 4-phenyl-7-hydroxy Coumarin; wherein, the molar ratio of sodium bisulfate monohydrate, resorcinol and ethyl benzoylacetate is 0.10:1:2, and the reaction time is 20min;

[0048] (2) Preparation of acrylic acid-4-phenyl-7-hydroxycoumarin ester: in the presence of hydroquinone, 10 mL of acrylic acid and dichloromethylene chloride react to obtain acryloyl chloride; in the presence of triethylamine, 4- Phenyl-7-hydroxycoumarin reacts with acryloyl chloride to obtain acrylate-4-phenyl-7-hydroxycoumarin ester; wherein, in the preparation reaction of acryloyl chloride, the amount ratio of acrylic acid and dichloromethylene chloride is 40mmol : 10mL, the reaction temperature is 50°C, and the reaction time is 1h; in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Gain coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com