Sulphate corrosion resistant curing agent for marine facies sludge curing

An anti-sulfate and curing agent technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve problems affecting curing strength and durability, structural expansion, and erosion of solidified soil, so as to prevent seawater erosion and reduce Effect of porosity, increased strength and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

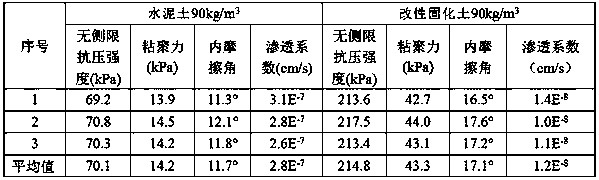

Examples

Embodiment 1

[0023] A kind of anti-sulphate corrosion curing agent for solidification of marine phase silt, in parts by weight, said curing agent is made of the following raw materials:

[0024] P.O 42.5 Portland cement: 2.3 parts;

[0025] S95 granulated blast furnace slag: 2.4 parts;

[0026] CL90 quicklime: 1.0 parts;

[0027] F.II grade fly ash: 1.8 parts;

[0028] Early strength enhancer: 1.0 parts;

[0029] Natural dihydrate gypsum: 0.1 parts;

[0030] Liquid stimulant: 0.2 parts.

[0031] The early-strength enhancer is made of silicon micropowder, calcium-based bentonite and metakaolin mixed in a mass ratio of 5:2:3, calcined at 800°C and ground to a specific surface area of 400m 2 / g of powder.

[0032] The liquid activator is a composite liquid prepared by mixing silica sol, polyacrylamide and triethanolamine in a mass ratio of 2:2:1, and stirring at a constant temperature of 80°C for 30 minutes.

Embodiment 2

[0034] A kind of anti-sulphate corrosion curing agent for solidification of marine phase silt, in parts by weight, said curing agent is made of the following raw materials:

[0035] P.O 42.5 Portland cement: 2.7 parts;

[0036] S95 granulated blast furnace slag: 2.9 parts;

[0037] CL90 quicklime: 1.5 parts;

[0038] F.II class fly ash: 2.4 parts;

[0039] Early strength enhancer: 1.5 parts;

[0040] Natural dihydrate gypsum: 0.3 parts;

[0041] Liquid stimulant: 0.5 parts.

[0042] The early-strength enhancer is made of silicon micropowder, calcium-based bentonite and metakaolin mixed in a mass ratio of 5:2:3, calcined at 800°C and ground to a specific surface area of 400m 2 / g of powder.

[0043] The liquid activator is a composite liquid prepared by mixing silica sol, polyacrylamide and triethanolamine in a mass ratio of 2:2:1, and stirring at a constant temperature of 80°C for 30 minutes.

Embodiment 3

[0045] A kind of anti-sulphate corrosion curing agent for solidification of marine phase silt, in parts by weight, said curing agent is made of the following raw materials:

[0046] P.O 42.5 Portland cement: 2.5 parts;

[0047] S95 granulated blast furnace slag: 2.6 parts;

[0048] CL90 quicklime: 1.3 parts;

[0049] F.II class fly ash: 2.1 parts;

[0050] Early strength enhancer: 1.2 parts;

[0051] Natural dihydrate gypsum: 0.2 parts;

[0052] Liquid stimulant: 0.3 parts.

[0053] The early-strength enhancer is made of silicon micropowder, calcium-based bentonite and metakaolin mixed in a mass ratio of 5:2:3, calcined at 800°C and ground to a specific surface area of 400m 2 / g of powder.

[0054] The liquid activator is a composite liquid prepared by mixing silica sol, polyacrylamide and triethanolamine in a mass ratio of 2:2:1, and stirring at a constant temperature of 80°C for 30 minutes.

[0055] Construction application:

[0056] (1) Mix uniformly according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com