Method for preparing nanometer TeO2 from aerosol through microwave assistance

A microwave-assisted, aerosol technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of not exploring the role of microwaves, and achieve the effects of easy amplification, short production cycle, and non-destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Synthetic raw materials: H 2 TeO 4 and water

[0032] (1) Weigh 1g H 2 TeO 4 In a 100mL beaker, ultrasonically stir for 10min until the drug in the beaker dissolves.

[0033] (2) Put the solution obtained in (1) into the aerosol generator, open the nitrogen cylinder, adjust the spray pressure of the aerosol generator to 200KPa, and make aerosol droplets through atomization.

[0034] (3) The aerosol droplets generated in (2) are introduced into the microwave generator (the power is 0), and then enter the tube furnace (the temperature is set to 600°C) to dry for 0.5s, and the dried particles are collected on the filter . The collected particles are TeO 2 Nano powder particles.

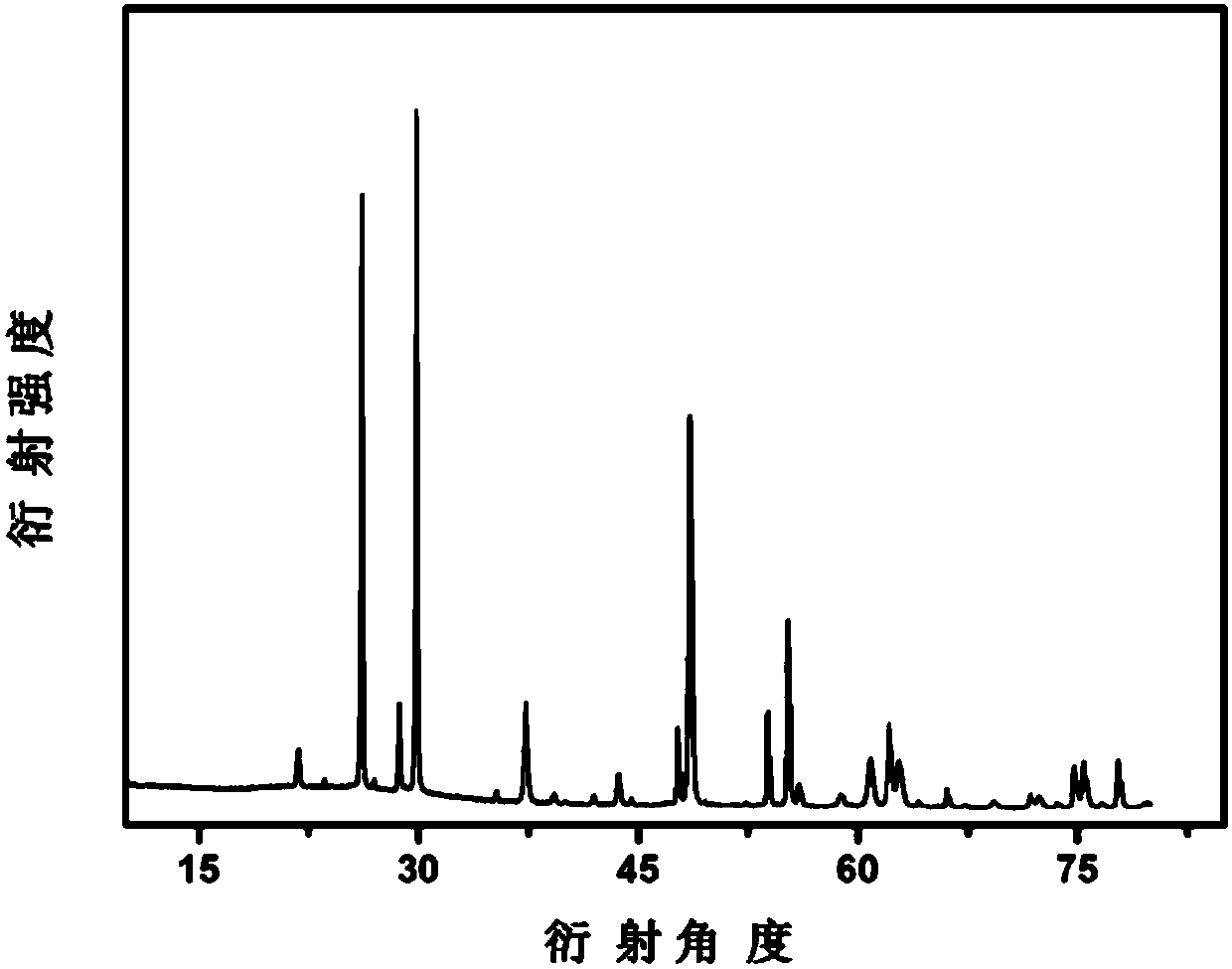

[0035] figure 1 TeO prepared for example 1 2 XRD patterns of nanoparticles; by figure 1 It can be seen that the nanopowder particles are TeO 2 Crystal, compared with the PDF card of TeO2, it can be found that it is consistent with the characteristic peak of card 42-1365.

[0036] fig...

Embodiment 2

[0038] Synthetic raw material: TeCl 4 and water

[0039] (1) Weigh 2g TeCl 4 In a 100mL beaker, ultrasonically stir for 10min until the drug in the beaker dissolves.

[0040] (2) Put the solution described in (1) into the aerosol generator, open the nitrogen cylinder, adjust the spray pressure of the aerosol generator to 200KPa, and make aerosol droplets through atomization.

[0041] (3) The aerosol droplets generated in (2) were introduced into a microwave generator (power 800KW), and then dried in a tube furnace (temperature set at 700°C) for 1 second, and the dried particles were collected on a filter. The collected particles are TeO2 Nano powder particles.

[0042] image 3 TeO prepared for Example 2 2 XRD patterns of nanoparticles; by image 3 It can be seen that the nanopowder particles are TeO 2 crystals. by TeO 2 The PDF card comparison found that it is consistent with the characteristic peak of the 8-484 card.

[0043] Figure 4 TeO prepared for Example 2 ...

Embodiment 3

[0045] Synthetic raw materials: H 2 TeO 4 and water

[0046] (1) Weigh 5g H 2 TeO 4 In a 100mL beaker, ultrasonically stir for 10min until the drug in the beaker dissolves.

[0047] (2) Put the solution described in (1) into the aerosol generator, open the nitrogen cylinder, adjust the spray pressure of the aerosol generator to 300KPa, and make aerosol droplets through atomization.

[0048] (3) The aerosol droplets generated in (2) were introduced into a microwave generator (power 800KW), and then dried in a tube furnace (temperature set at 900°C) for 1 second, and the dried particles were collected on a filter. The collected particles are TeO 2 Nano powder particles.

[0049] Figure 5 TeO prepared for Example 3 2 XRD patterns of nanoparticles; by Figure 5 It can be seen that the nanopowder particles are TeO 2 crystals. by TeO 2 A PDF card comparison of the 8-484 can be found, which matches the Trump card of 8-484. pass figure 1 , image 3 , Figure 5 It can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com