Liquefied natural gas (LNG) cylinder frame for commercial vehicle

A technology for commercial vehicles and gas cylinders, which is applied to vehicle components, layout combined with internal combustion engine fuel supply, power units, etc. lightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

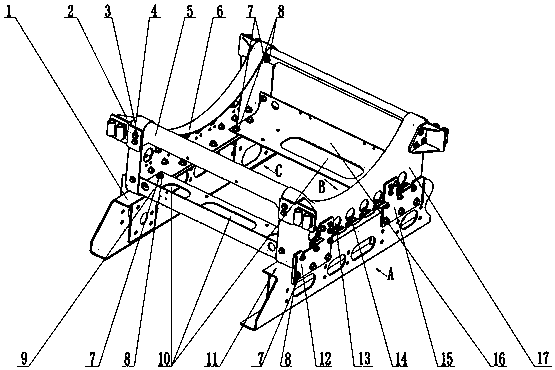

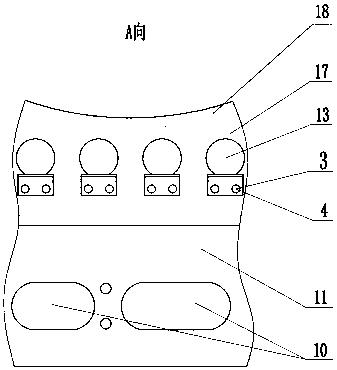

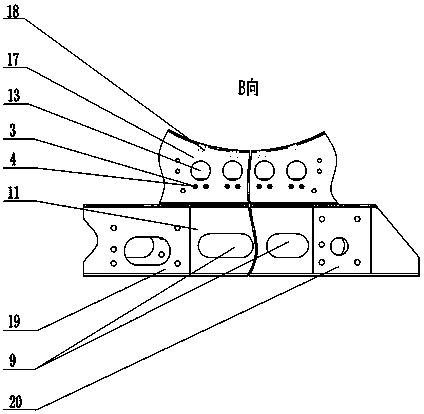

[0019] Such as figure 1 As shown, the commercial vehicle LNG gas cylinder frame provided by this embodiment includes a left bottom beam 1 and a left saddle 6, a right bottom beam 11 and a right saddle 17, and the left bottom beam 1 and the left saddle 6 adopt multiple A large self-locking bolt 7 and a large self-locking nut 8 are connected into one body by means of a connecting plate one 12 and a connecting plate two 15, and the right bottom beam 11 and the right saddle 17 adopt a plurality of large self-locking bolts 7 and large self-locking nuts The lock nut 8 is integrated with the second connecting plate 15 by means of the connecting plate one 12, and the assembly formed by connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com