Modified resin catalyst and method for removing residual formaldehyde in 3-methyl-3-butene-1-ol solution

A technology for modifying resins and catalysts, used in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc. Incomplete, product loss and other problems, to achieve good formaldehyde removal effect, reduce catalyst loss, reduce equipment investment and operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of modified resin catalyst:

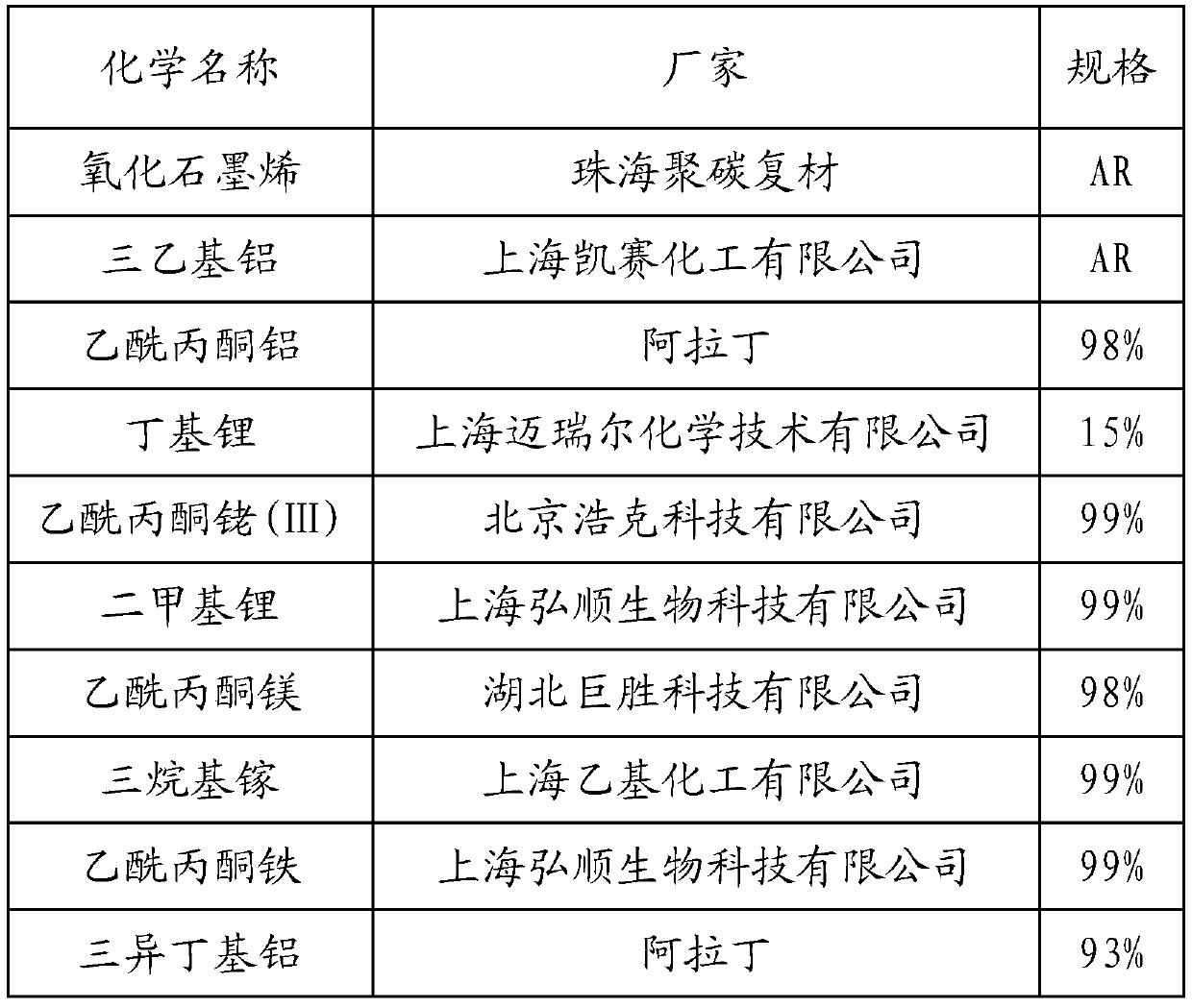

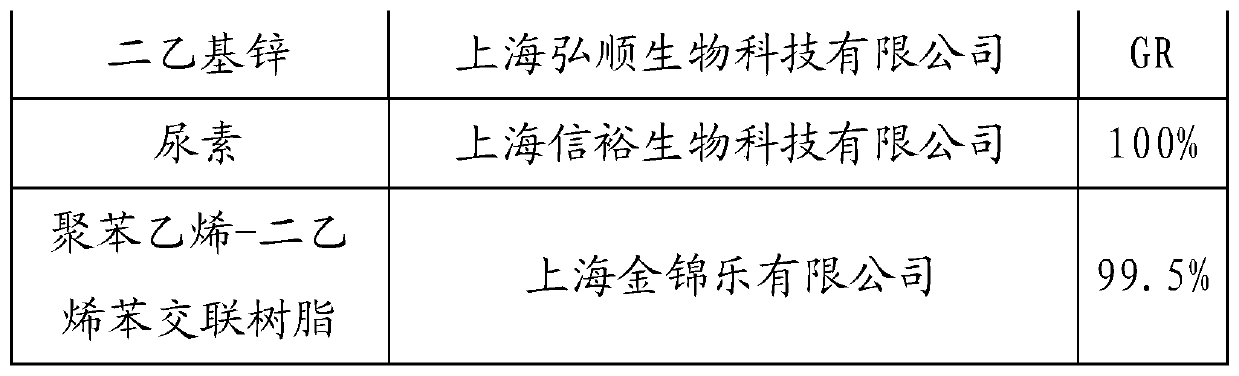

[0042] Take 200g of polystyrene-divinylbenzene crosslinking resin (hereinafter referred to as "crosslinking resin") and add it to the chloroform solution, add 0.5wt% graphene oxide of the mass of the crosslinking resin, mix it with ultrasound for 1 hour, and then heat to remove the solvent; The resin was washed three times with ethanol, and then washed with 50 wt % sodium hydroxide aqueous solution until the pH was greater than 10, and finally the resin was put into an oven at 160° C. for 10 h to obtain a modified resin. Add the modified resin to a 2000ml three-necked bottle with a condenser, protect it with nitrogen, and then add 600ml of toluene to soak for 6h; start stirring, and add 2wt% triethylaluminum and 0.3wt% aluminum acetylacetonate (both based on cross-linked resin mass), heated to 120°C and stirred for 3 hours, then lowered the temperature, cooled and filtered to obtain a modified resin catalyst, washed with ethanol...

Embodiment 2

[0046] Preparation of modified resin catalyst:

[0047] Take 200g of polystyrene-divinylbenzene crosslinking resin and add it to the chloroform solution, add 0.5wt% graphene oxide of the mass of the crosslinking resin, mix with ultrasound for 1h, and then heat to remove the solvent; wash the resin 3 times with ethanol, and then use 50wt% The sodium hydroxide aqueous solution was washed until the pH was greater than 10, and finally the resin was dried in an oven at 160° C. for 10 hours to obtain a modified resin. Add the modified resin into a 2000ml there-necked bottle with a condenser and protect it with nitrogen, then add 600ml of toluene and soak for 6h; start stirring, add 4wt% butyllithium and 0.8wt% rhodium acetylacetonate (both based on crosslinked resin mass), heated to 110°C and stirred for 4h, then cooled down and filtered to obtain a modified resin catalyst, washed with ethanol for 3 times, and then dried in a 180°C oven for 24h. In the prepared modified resin catal...

Embodiment 3

[0051] Preparation of modified resin catalyst:

[0052] Take 200g of polystyrene-divinylbenzene crosslinking resin and add it to the chloroform solution, add 0.5wt% graphene oxide of the mass of the crosslinking resin, mix with ultrasound for 1h, and then heat to remove the solvent; wash the resin 3 times with ethanol, and then use 50wt% The sodium hydroxide aqueous solution was washed until the pH was greater than 10, and finally the resin was dried in an oven at 160° C. for 10 hours to obtain a modified resin. Add the modified resin into a 2000ml there-necked bottle with a condenser and protect it with nitrogen, then add 600ml of toluene and soak for 6h; start stirring, add 6wt% dimethyllithium and 1.5wt% magnesium acetylacetonate (based on the quality of the cross-linked resin ), heated to 120° C. and stirred for 3 h, then lowered the temperature, cooled and filtered to obtain a modified resin catalyst, washed the obtained modified resin catalyst with ethanol three times, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com