Adsorbent for adsorption treatment of electroplating wastewater

A technology for adsorption treatment and electroplating wastewater, which is used in metallurgical wastewater treatment, adsorption water/sewage treatment, water/sewage treatment, etc., to achieve good adsorption effect, high adsorption efficiency, and improve adsorption stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

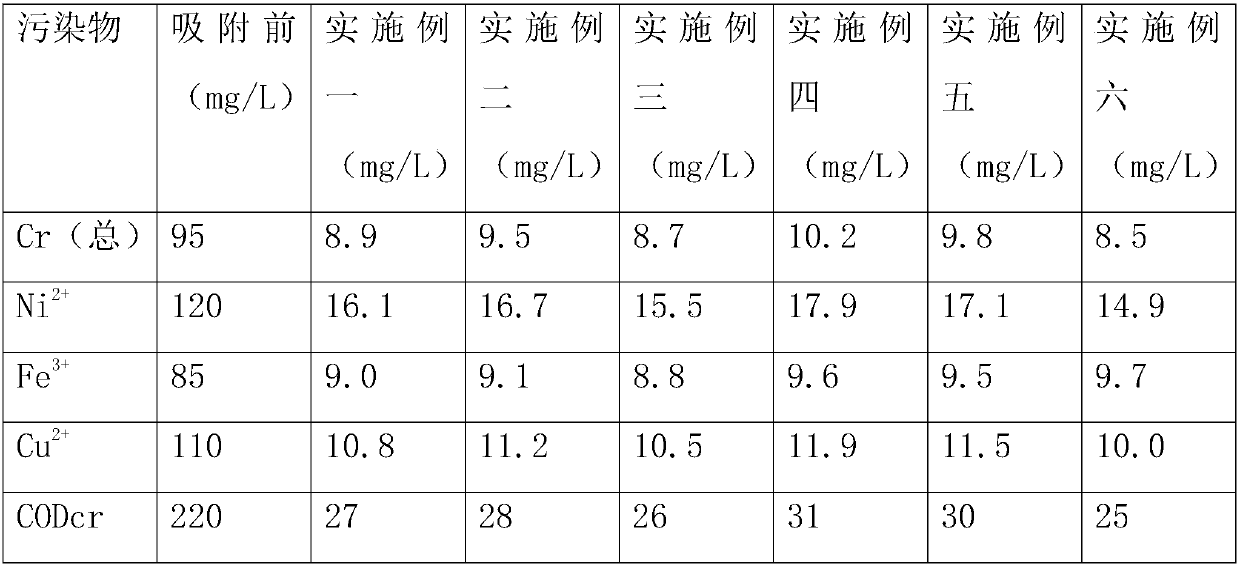

Examples

preparation example Construction

[0036] In the present embodiment, the preparation method of described adsorbent comprises the following steps:

[0037] (1) Mix the nano ferric ferric oxide and the lipase solution and adjust the pH of the mixture to 6.0-7.0, then place the mixture at about 25° C. and stir for at least 1 hour;

[0038] (2) Add sodium humate to the mixture obtained in step (1), continue stirring for at least 15 minutes, then add sodium carboxymethyl starch, bamboo charcoal powder, medical stone powder, sulfonated coal, polyaluminum chloride and polyaluminum chloride Acrylamide, just mix well.

Embodiment 1

[0041] For the adsorbent used in the adsorption treatment of electroplating wastewater provided in this example, the raw materials of the adsorbent include the following components in parts by weight: 23 parts of sulfonated coal, 16 parts of medical stone powder, 28 parts of lipase liquid, humic 6 parts of sodium bicarbonate, 16 parts of nano iron ferric oxide, 17 parts of sodium carboxymethyl starch, 6 parts of polyaluminum chloride, 10 parts of bamboo charcoal powder, and 4 parts of polyacrylamide.

[0042] In this embodiment, the lipase liquid is prepared by mixing the lipase liquid produced by the secretion of Pseudomonas fluorescens and the lipase liquid produced by the secretion of Pseudomonas aeruginosa in a mass ratio of 3:2;

[0043] in:

[0044] The cultivation method of Pseudomonas fluorescens and Pseudomonas aeruginosa comprises the steps:

[0045] (1) Preparation of beef extract liquid medium: Weigh 30g of beef extract, 15g of peptone and 15g of sodium chloride a...

Embodiment 2

[0060] For the adsorbent used in the adsorption treatment of electroplating wastewater provided in this example, the raw materials of the adsorbent include the following components in parts by weight: 23 parts of sulfonated coal, 15 parts of medical stone powder, 25 parts of lipase liquid, humic 8 parts of sodium bicarbonate, 18 parts of nano iron ferric oxide, 16 parts of sodium carboxymethyl starch, 5 parts of polyaluminum chloride, 12 parts of bamboo charcoal powder, and 4 parts of polyacrylamide.

[0061] In the present embodiment, the lipase liquid produced by the secretion of Pseudomonas fluorescens and the lipase liquid produced by Pseudomonas aeruginosa are mixed in a mass ratio of 3:2; wherein, Pseudomonas fluorescens And the culture method of Pseudomonas aeruginosa and the extraction method of its lipase liquid are the same as embodiment one.

[0062] In this example:

[0063] The particle size of the sulfonated coal is 1.0mm; the particle size of the bamboo charcoa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com