Household soybean milk and bean curd machine

A technology of tofu machine and soy milk, which is applied to household appliances, applications, kitchen utensils, etc., can solve the problems of clogging of raw materials, large size of the machine, lack of stirring, etc., to improve the taste of food, reduce the size of the whole machine, and be easy to disassemble and clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

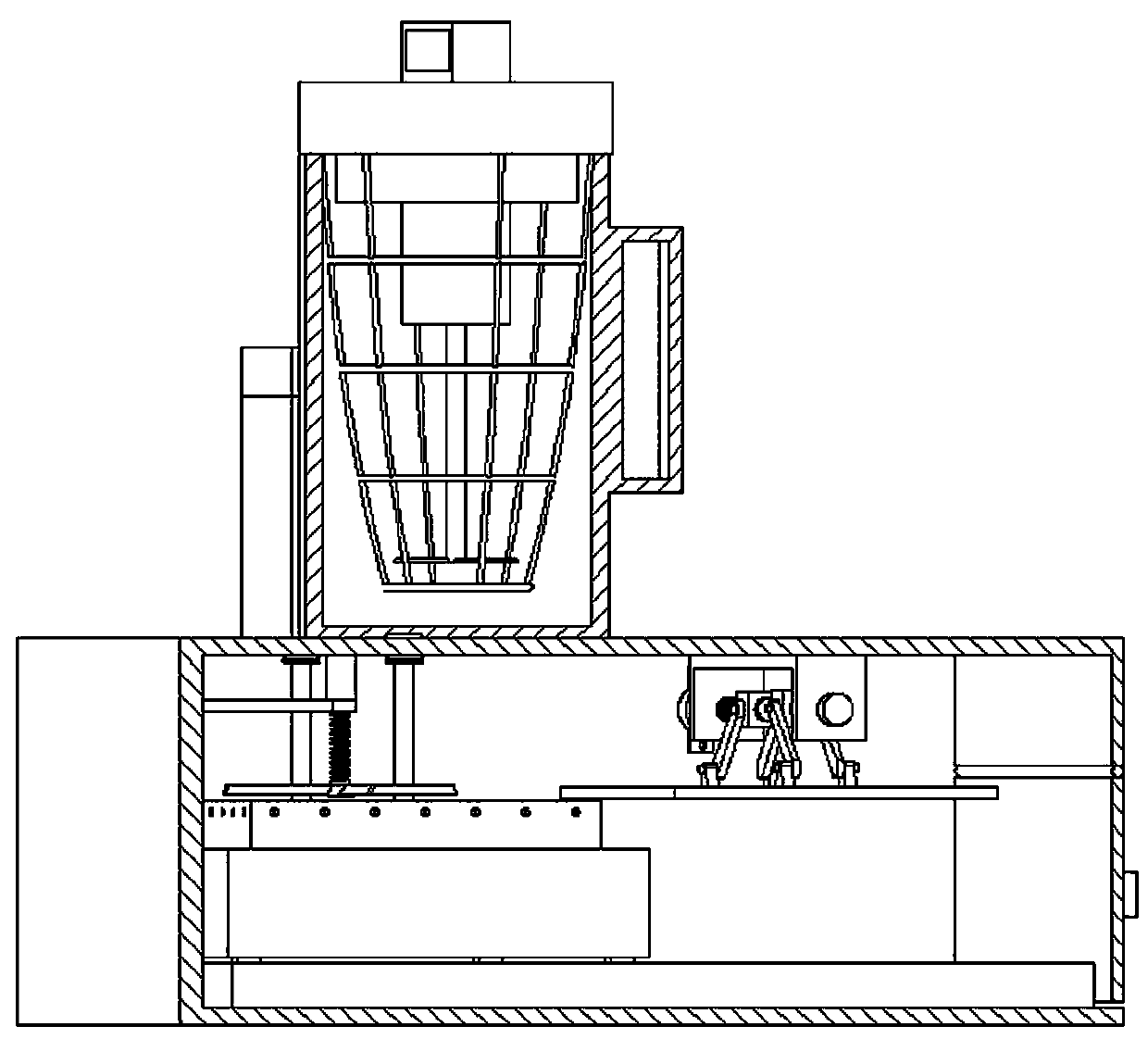

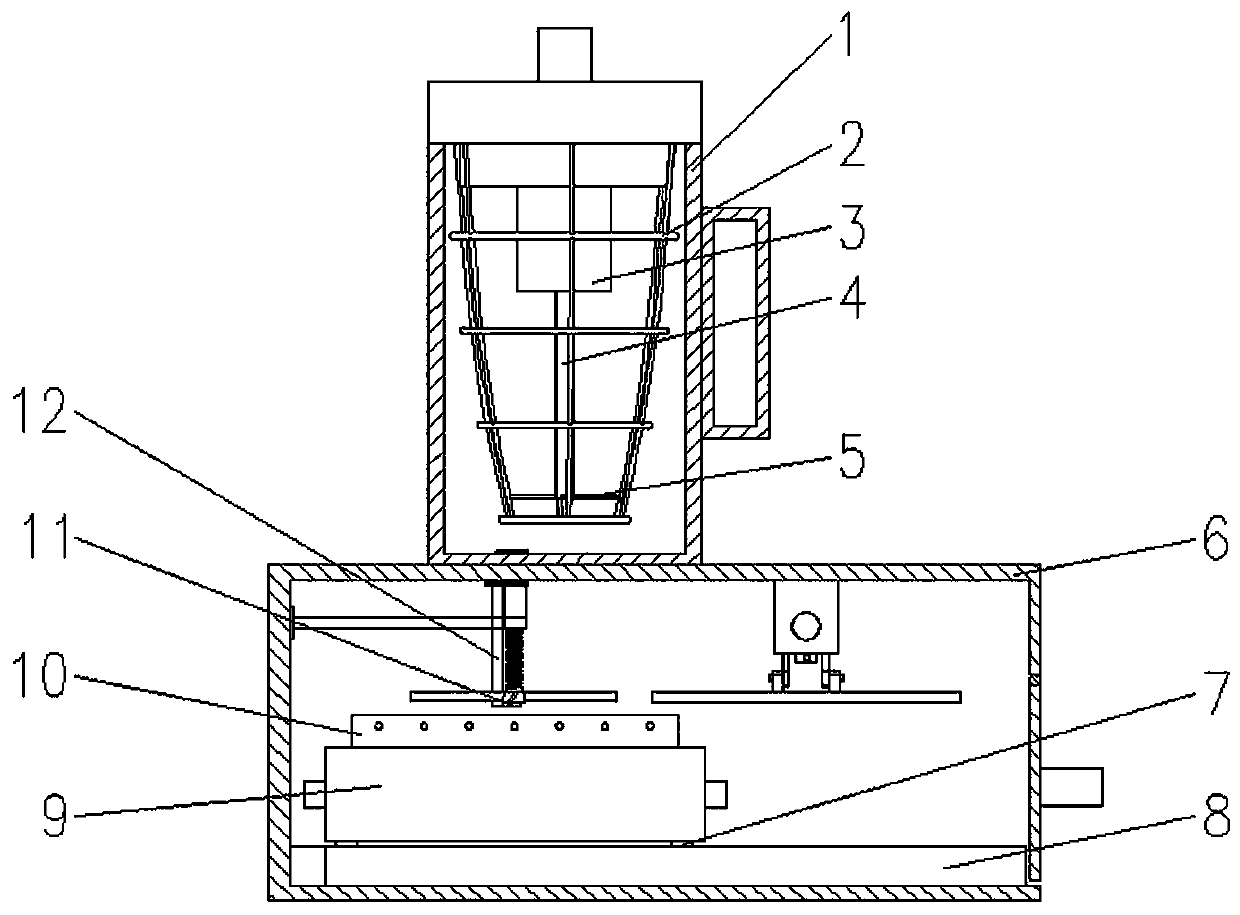

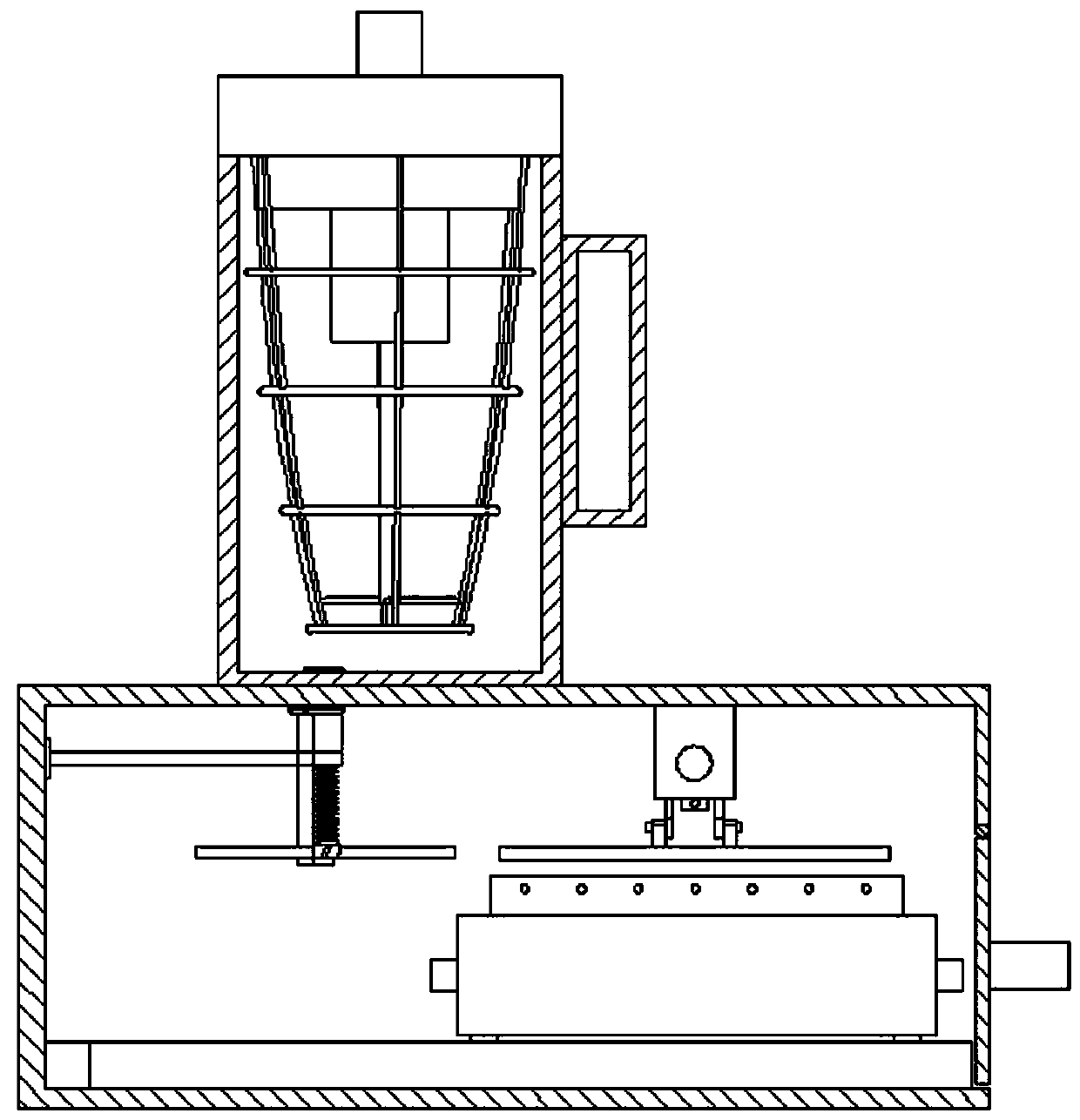

[0024] Embodiment 1, the present invention includes a pulping assembly, a brine box and a main box assembly, and the pulping assembly and the brine box are placed on the main box assembly; the pulping assembly includes a beating cup 1, a filter screen 2, Motor 3, motor shaft 4 and cutter 5, motor 3 is fixed on the beating cup body cover, motor shaft 4 goes deep into the cup body vertically and is placed in the filter screen 2, the lower end of motor shaft 4 is connected to cutter 5; the main box assembly includes Cabinet 6, diversion pipe A11 and diversion pipe B12, tofu forming box 10, waste water box 9, stirring mechanism, extruding mechanism and conveying mechanism, the stirring mechanism and extruding mechanism are fixed on the top of the casing 6, and the conveying mechanism is installed At the bottom of the box body 6, the tofu forming box 10 is placed in the middle of the waste water box 9, the waste water box 9 is installed on the conveying mechanism, the guide pipe A11...

Embodiment 2

[0025] Embodiment 2, the inner wall of the beating cup 1 is provided with a heating element for cooking pulp. refer to Figure 1 to Figure 7 , all the other are with embodiment 1.

Embodiment 3

[0026] Embodiment 3, the filter screen 2 can be taken out from the cup body, which facilitates the processing and cleaning of bean dregs. refer to Figure 1 to Figure 7 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com