Reflective composite material having a varnished aluminum carrier having a silver reflection layer and method for production thereof

A composite material and reflective technology, which is applied in the direction of reflection/signal coatings, chemical instruments and methods, coatings, etc., can solve the problems of loss of reflection ability, etc., and achieve corrosion promotion, excellent adhesion, and long-term light total reflectance maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

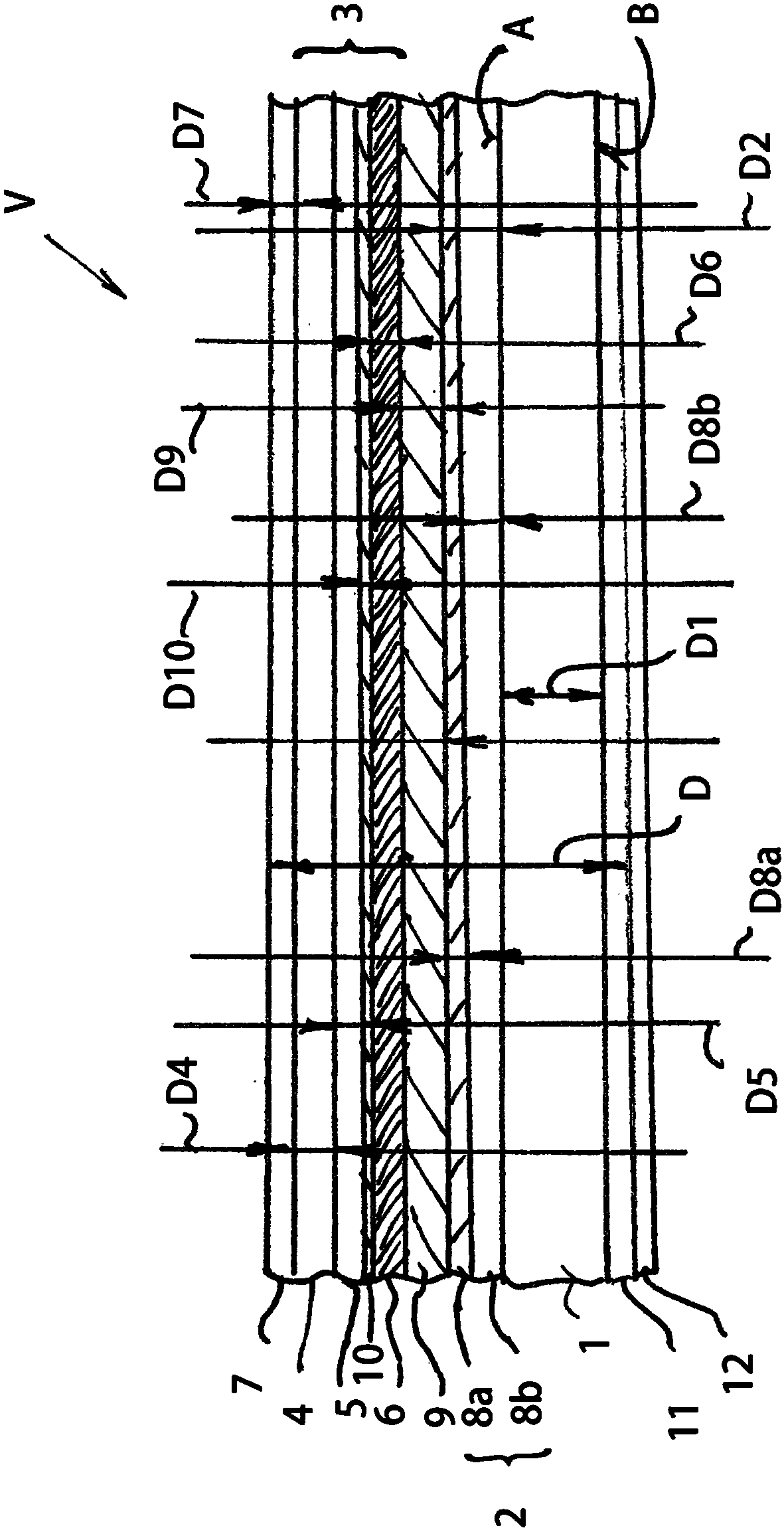

[0059] The described embodiment relates to a composite material V according to the invention having a high reflectivity, especially in the solar wavelength range. It can preferably be arranged to reflect optical radiation, ie electromagnetic radiation in the wavelength range from 100 nm to 1 mm.

[0060] The composite material V comprises, in particular, a deformable strip-shaped substrate 1 made of aluminum, an intermediate layer 2 on one side A of the substrate 1 and an optically active multilayer system applied over the intermediate layer 2 3.

[0061] The total light reflectance determined according to DIN 5036 part 3 on side A of the optical multilayer system 3 is greater than 90%, preferably at least 95%, particularly preferably at least 97%.

[0062] The composite material V can preferably be configured with a width of up to 1600 mm, preferably 1400 mm, and, including any layers present on its rear side B, a thickness D of approximately 0.2 mm to 1.7 mm, preferably app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Arithmetic mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com