Efficient desulfurization dust removing device

A desulfurization dust collector, desulfurization and dust removal technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve problems such as easy blockage, high energy consumption, low efficiency, etc., to increase corrosion and save water resources. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

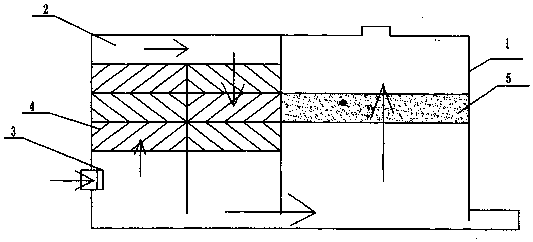

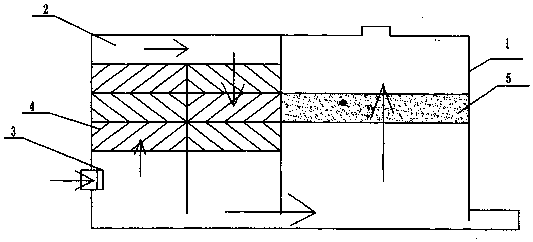

[0007] The high-efficiency desulfurization and dust collector of the present invention is composed of: desulfurization and dust removal main equipment 1, flue gas channel 2, high-efficiency anti-blocking atomizer 3, packing 4, and gas-liquid separation device 5. The technical solution adopted is: in the high-efficiency anti-blocking atomization Packing is installed under the device, and the flue gas is sent to the desulfurization and dust removal main equipment 1 by the induced draft fan, and the flue gas passes through the high-efficiency anti-blocking atomizer 3, and its function is to make the sprayed mist absorbing liquid and the sulfur dioxide and sulfur dioxide in the flue gas The smoke and dust are fully contacted to achieve the effect of desulfurization and dust removal. The filler 4 is granite. Its function is to further mix and contact the absorption liquid with the flue gas. The mist water that has absorbed sulfur dioxide and smoke passes through the filler to form li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com