Heat shrinkable polyester film and package

A technology of heat shrinkage and film, applied in the direction of transportation and packaging, packaging, wrapping paper, etc., can solve the problems of high shrinkage stress, poor solvent resistance, low heat resistance, etc., and achieve the effect of low shrinkage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to the forms of these examples at all, and can be appropriately changed within a range not departing from the gist of the present invention. The compositions of the raw materials used in Examples and Comparative Examples, the production conditions of the films in Examples and Comparative Examples, and the evaluation results of the films in Examples and Comparative Examples are shown in Table 1, Table 2, and Table 3, respectively.

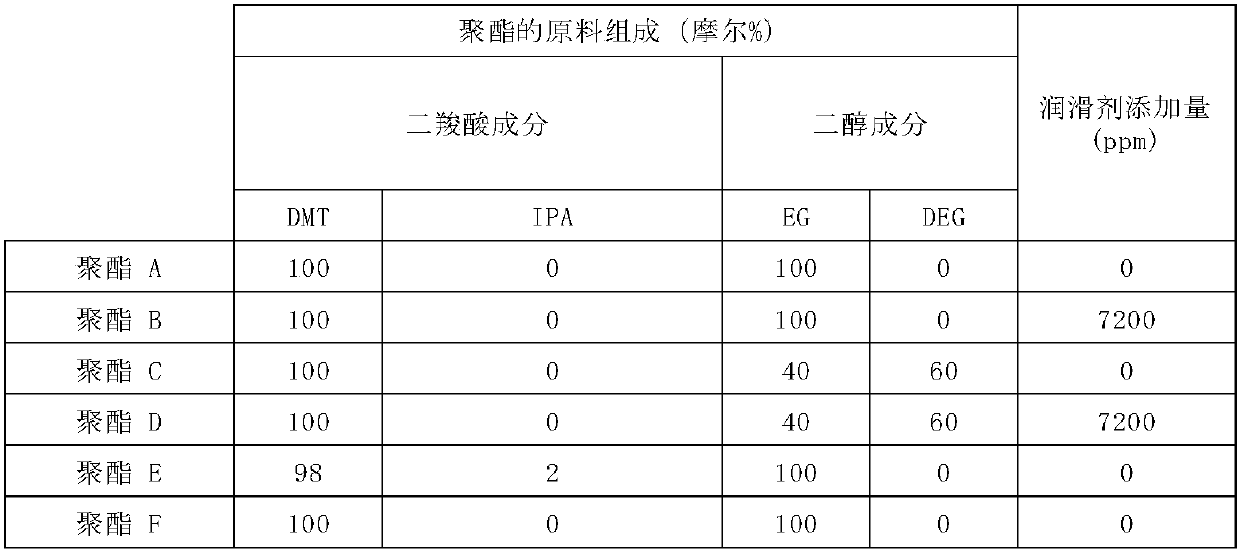

[0076] [Table 1]

[0077]

[0078] [Table 2]

[0079]

[0080] [table 3]

[0081]

[0082] In addition, the evaluation method of the film is as follows.

[0083] [Tg (glass transition point)]

[0084] Using a differential scanning calorimetry analyzer (manufactured by Seiko Denshi Kogyo Co., Ltd., DSC220), 5 mg of an unstretched film was placed in a sample pan, the lid of the pan was closed, and the tempe...

Synthetic example B~D

[0110] Polyesters B to D shown in Table 1 were obtained by the same method as in Synthesis Example 1. When manufacturing polyesters B and D, SiO is added as a lubricant at a ratio of 7200ppm relative to the polyester 2 (Sylysia 266 manufactured by Fuji Sylysia Co., Ltd.; average particle diameter: 1.5 μm). It should be noted that DEG in the table is diethylene glycol. The intrinsic viscosities of the respective polyesters were B: 0.7 dl / g, C: 0.65 dl / g, and D: 0.65 dl / g. In addition, each polyester is suitably formed into a chip shape.

[0111] In addition, polyester E is a recycled raw material ("Clearpellet" manufactured by Petbottle Recycling Co., Ltd.), and its intrinsic viscosity is 0.63 dl / g. In addition, as described in Table 1, this polyester E contains isophthalic acid (2 mol%) with respect to all the dicarboxylic acid components constituting the polyester.

[0112] For polyester F, a resin was prepared by the following production method. To a mixture of terephth...

Embodiment 1

[0114] The above-mentioned polyester A, polyester C and polyester D were mixed at a weight ratio of 87:7:6, and charged into an extruder. Thereafter, the mixed resin was melted at 280° C., extruded from a T die, wound on a rotating metal roll whose surface temperature was cooled to 30° C., and quenched to obtain an unstretched film with a thickness of 162 μm. The Tg of the unstretched film was 72°C. Thereafter, this unstretched film was introduced into a transverse stretching machine (hereinafter referred to as a tenter). Then, the unstretched film introduced into the tenter was preheated until the film temperature reached 100°C (Tg+28°C), and then stretched 4.5 times in the transverse direction at 90°C (Tg+18°C). Furthermore, the film stretched horizontally in this way is introduced into a vertical stretching machine in which a plurality of roll groups are continuously arranged, preheated on the preheating roll until it reaches 90°C (Tg+18°C), and stretched using the speed d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com