Device for driving vehicle

An automobile driving device and automobile technology, which is applied in power plant, electric power plant, pneumatic power plant, etc., can solve the problems of inability to generate shaft torque, difficulty in ensuring MG installation space, and difficulty in realizing hybrid vehicles, etc. The effect of reducing probability, preventing short circuit, reducing shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

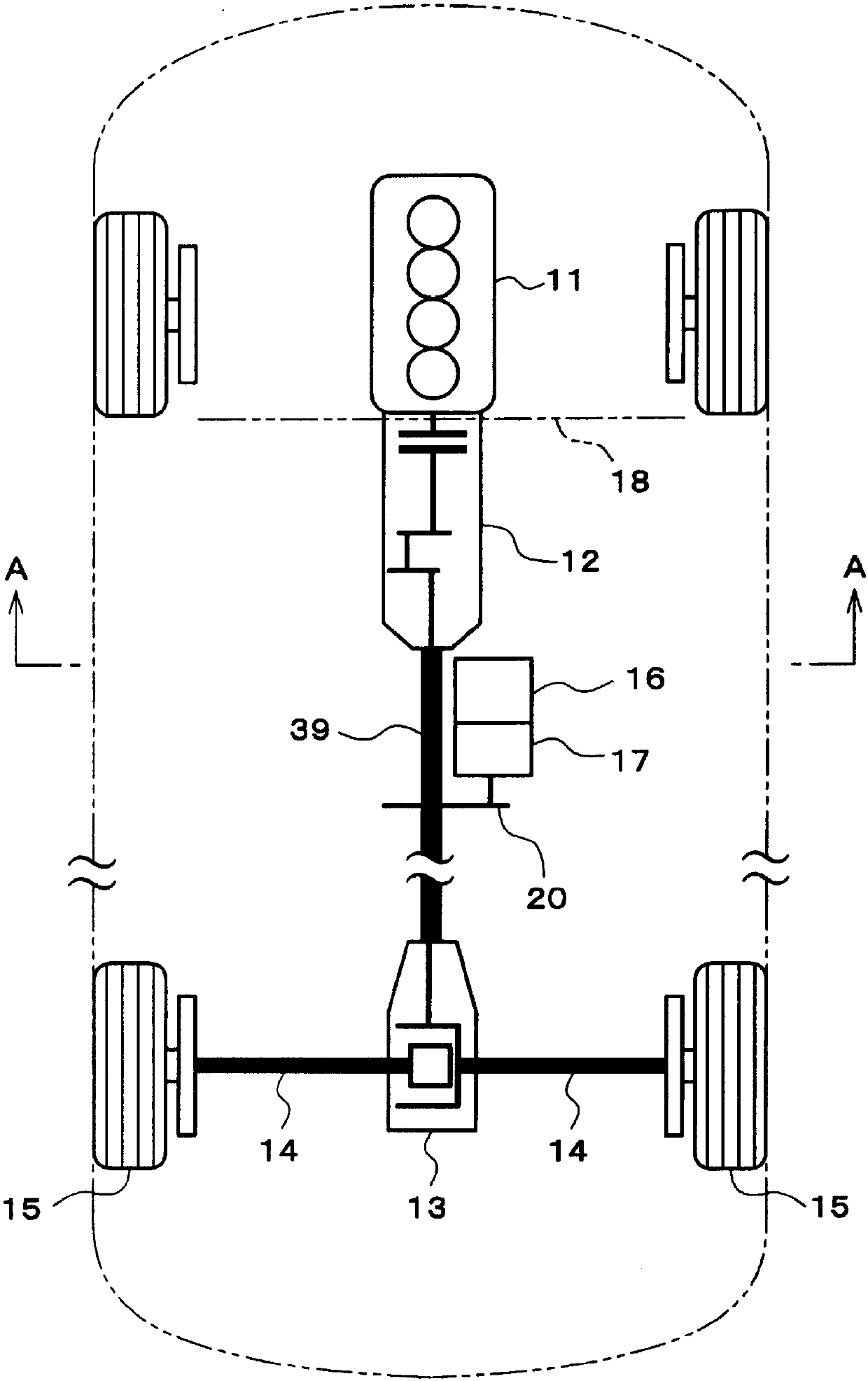

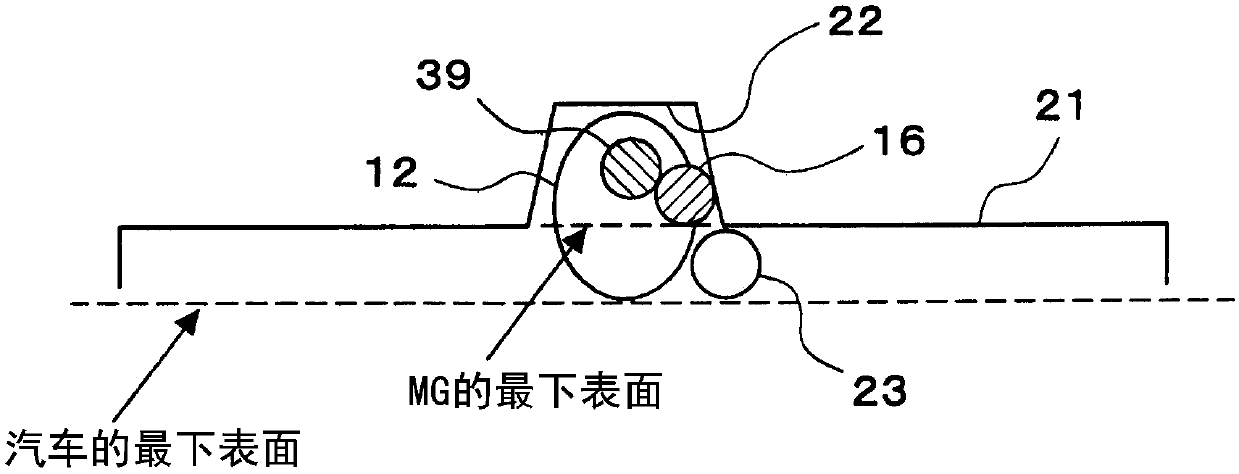

[0043] according to Figure 1 to Figure 5 , the first embodiment will be described. First, according to figure 1 with figure 2 , a schematic configuration of a drive system of a hybrid vehicle will be described.

[0044] Such as figure 1 As shown, an engine 11 serving as a power source of the automobile and a transmission 12 connected to the above-mentioned engine 11 are mounted on the front side of the automobile. The transmission 12 is a mechanical transmission, and may be a stepping transmission that switches gears step by step from a plurality of gears, or may be a CVT (continuously variable transmission) that changes gears continuously. The above-mentioned engine 11 and transmission 12 are arranged longitudinally so that the axial direction of the output shaft (crankshaft) of the engine 11 is the front-rear direction of the vehicle. The power of the output shaft of the engine 11 is transmitted to the transmission 12, and the power of the output shaft of the transmis...

Embodiment 2

[0070] Next, use Image 6 Embodiment 2 will be described. However, the same symbols are attached to the parts substantially the same as those of the first embodiment described above, and descriptions thereof are omitted or simplified, and the parts different from the first embodiment described above will be mainly described.

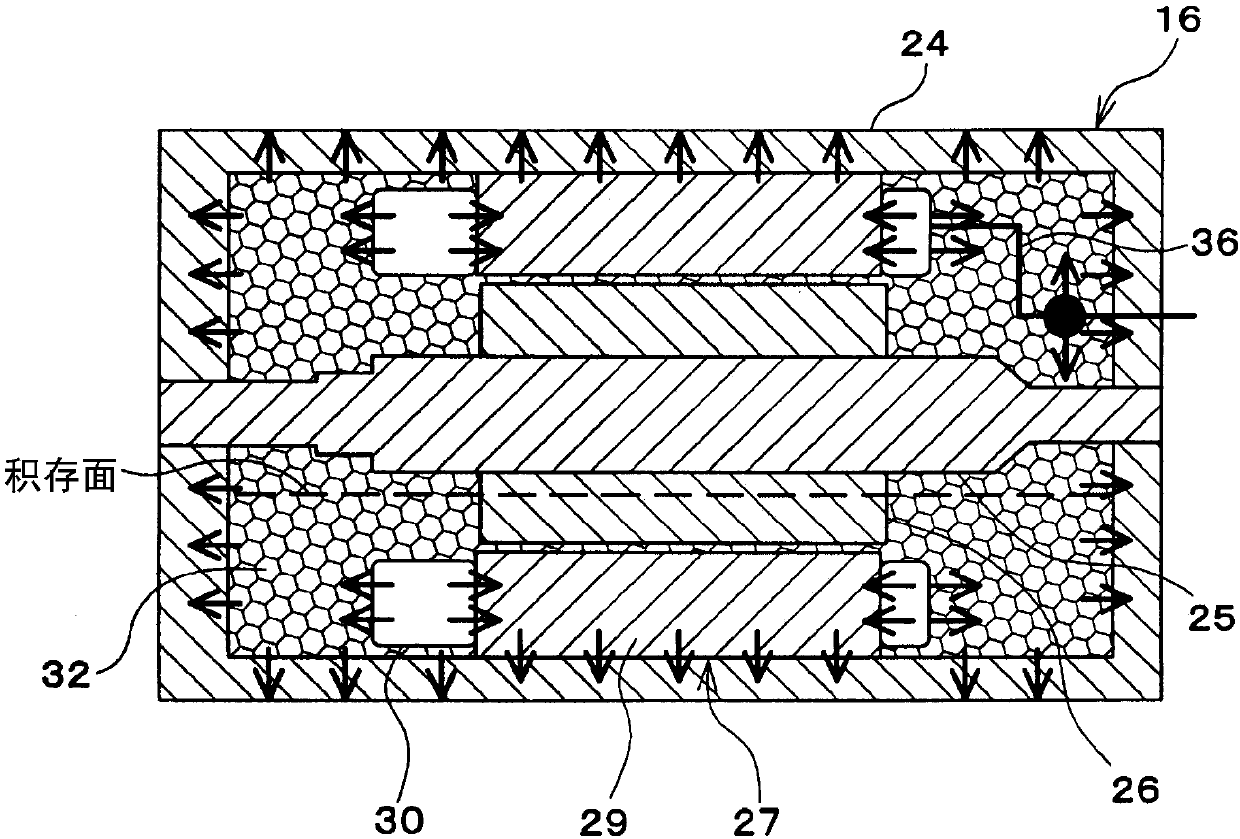

[0071] Such as Image 6 As shown, in the second embodiment, in the case 24 of the MG 16 , on both sides in the axial direction of the stator core 29 , solid bodies 37 for heat dissipation are provided respectively. The aforementioned solid body 37 is arranged to be in contact with at least the coil end portion of the stator winding 30 (portion protruding from the axial end surface of the stator core 29 ) and the inner surface (inner peripheral surface and axial inner surface) of the case 24 . By this, if Image 6 As indicated by arrows in , the heat at the coil ends of the stator winding 30 of MG 16 can be transferred to case 24 via solid 37 to be dis...

Embodiment 3

[0075] Next, use Figure 7 Embodiment 3 will be described. However, the same symbols are attached to the parts substantially the same as those of the first embodiment described above, and descriptions thereof are omitted or simplified, and the parts different from the first embodiment described above will be mainly described. Such as Figure 7 As shown, in the third embodiment, between the output shaft of the speed reducer 17 and the power transmission mechanism 20, a clutch 38 for cutting off or connecting the power transmission is provided. The aforementioned clutch 38 may be a hydraulically driven plate clutch, may also be an electromagnetically driven electromagnetic clutch, or may be a mechanical claw clutch. The clutch 38 is provided separately from the speed reducer 17 (that is, it is provided outside the housing of the speed reducer 17). In addition, the clutch 38 may be provided integrally with the speed reducer 17 (that is, the clutch 38 may be provided in the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com