Composite adhesive and preparation method and application thereof

A binder and curing agent technology, applied in the direction of carbide, calcium carbide, etc., can solve the problems of unable to maintain the thermal strength of the pellets, unable to reach high temperature, low temperature, etc., to improve the strength, improve the cold and hot strength, and improve the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

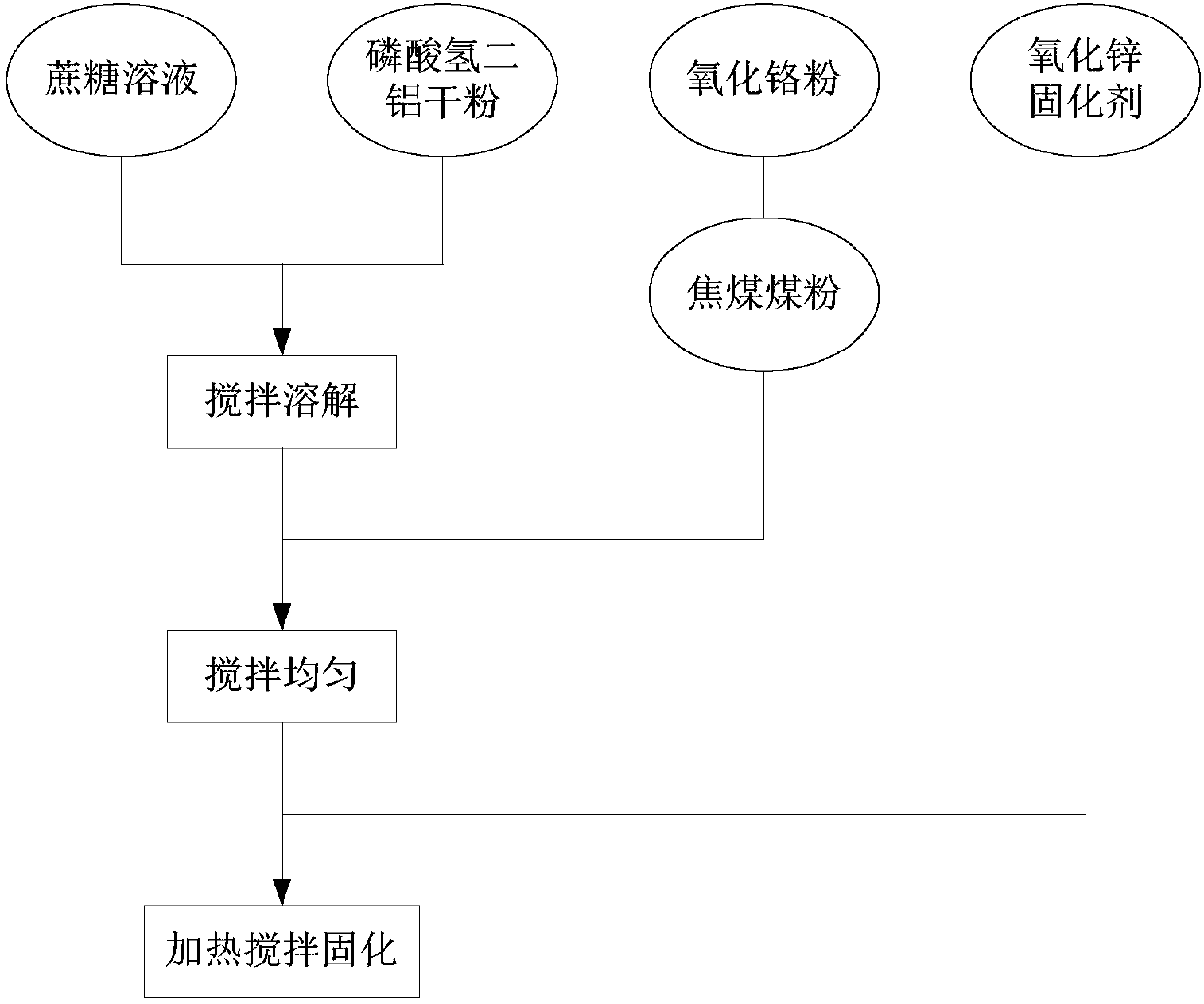

[0029] like figure 1 Shown, according to the preparation method of composite binder of the present invention mainly comprises the following steps:

[0030] 1a) Prepare each component according to the formula ratio, add dialuminum hydrogen phosphate dry powder into the sucrose solution, and stir evenly until completely dissolved;

[0031] 1b) Add dry chromium oxide powder and coking coal coal powder to the mixture obtained in 1a), and stir evenly;

[0032] 1c) Add a zinc oxide curing agent to the mixture obtained in 1b), and stir evenly until a gel-like liquid-solid mixture is formed to obtain a composite binder.

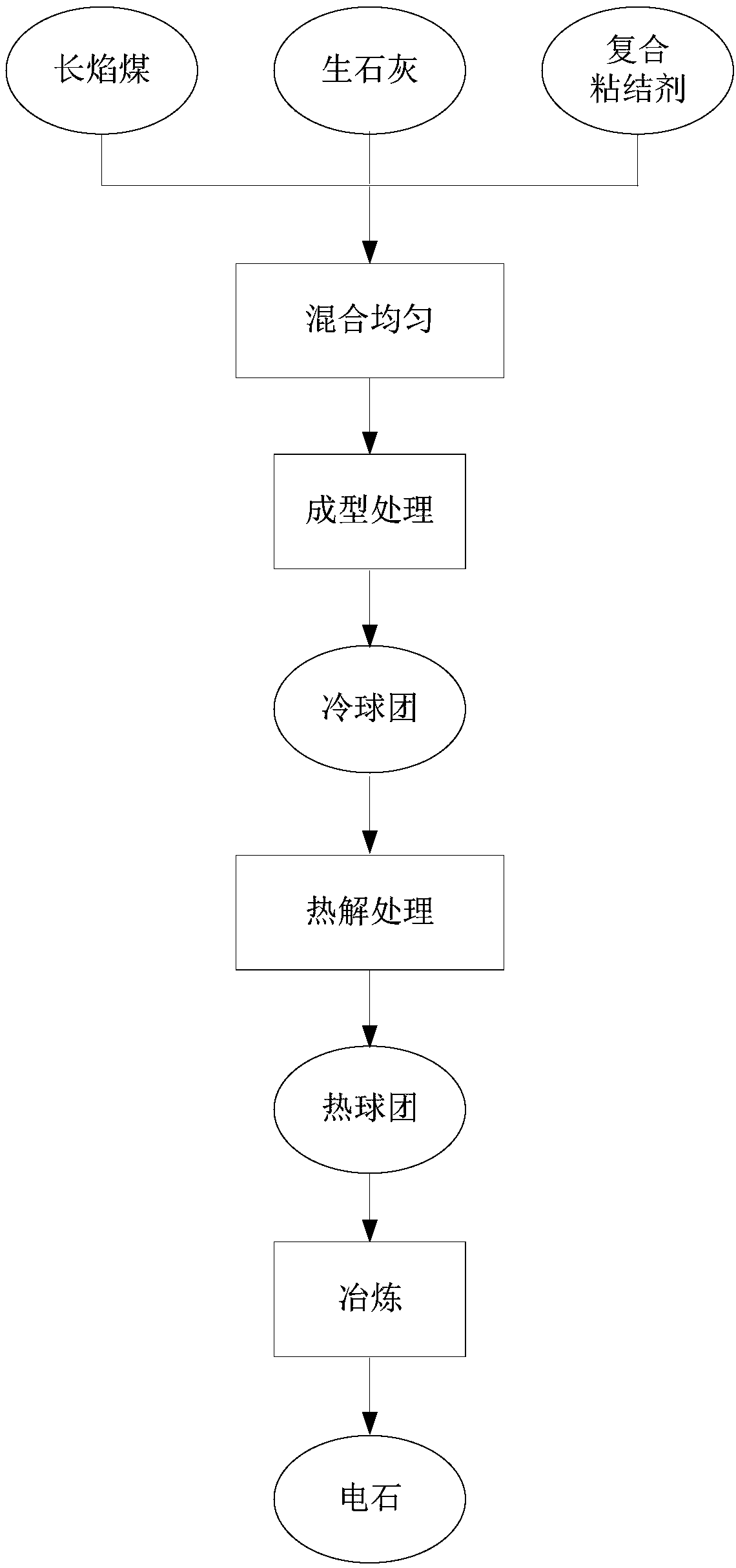

[0033] like figure 2 As shown, utilizing the composite binder prepared by the above-mentioned method to prepare high-quality calcium carbide generally comprises the following steps:

[0034] 2a) Mix long-flame coal, quicklime and composite binder uniformly in a weight ratio of 1:1-1.3:0.1-0.2;

[0035] 2b) The mixture is molded by a roller briquetting machine in...

Embodiment 1

[0039] The preparation method of the composite binder of the embodiment of the present invention 1 comprises the following steps:

[0040] 1a) Add 25kg of dialuminum hydrogen phosphate dry powder into 100kg of sucrose solution with a concentration of 30wt%, and stir evenly until completely dissolved;

[0041] 1b) Add 8 kg of chromium oxide dry powder with a particle size not greater than 50 μm and 25 kg of coking coal powder with a particle size not greater than 150 μm into the mixture obtained in 1 a), and stir evenly;

[0042] 1c) Add 4 kg of zinc oxide curing agent with a particle size not greater than 50 μm to the mixture obtained in 1b), and stir evenly until a gel-like liquid-solid mixture is formed to obtain a composite binder.

[0043] Using the composite binder prepared by the above method to prepare high-quality calcium carbide generally includes the following steps:

[0044] 2a) Mix 100kg of long-flame coal with a particle size not greater than 150 μm, 110 kg of qu...

Embodiment 2

[0049] The preparation method of the composite binder of the embodiment of the present invention 2 comprises the following steps:

[0050] 1a) Add 20kg of dialuminum hydrogen phosphate dry powder into 100kg of sucrose solution with a concentration of 30wt%, and stir evenly until completely dissolved;

[0051] 1b) Add 6 kg of chromium oxide dry powder with a particle size not greater than 100 μm and 23 kg of coking coal powder with a particle size not greater than 300 μm to the mixture obtained in 1 a), and stir evenly;

[0052] 1c) Add 3 kg of zinc oxide curing agent with a particle size not greater than 100 μm to the mixture obtained in 1b), and stir evenly until a gel-like liquid-solid mixture is formed to obtain a composite binder.

[0053] Using the composite binder prepared by the above method to prepare high-quality calcium carbide generally includes the following steps:

[0054] 2a) Mix 100kg of long-flame coal with a particle size not greater than 500 μm, 100 kg of qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com