Ticagrelor dispersible tablet and preparation method thereof

A technology for ticagrelor and dispersible tablets, applied in the field of ticagrelor dispersible tablets and their preparation, can solve the problems of low bioavailability of ticagrelor, poor patient compliance with the dissolution rate of ticagrelor, etc. The effect of crystal transformation and impurity increase, good process reproducibility and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

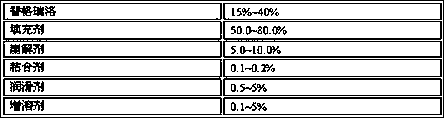

Image

Examples

Embodiment 1

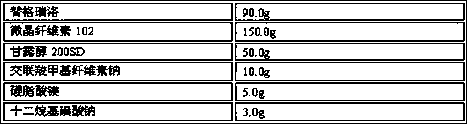

[0031] Ticagrelor dispersible tablets are prepared from the following components, according to the dosage of 1000 tablets

[0032]

[0033] Its preparation method comprises the following steps:

[0034] 1) Micronize ticagrelor to a particle size of <20µm;

[0035] 2) Add sodium carboxymethyl starch and mannitol three times in equal amounts, mix for 15 minutes, and the speed of the mixer is 10 rpm to obtain the mixture (1)

[0036] 3) Add ticagrelor to the mixture (1) obtained in step 2, the mixing time is 15 minutes, the speed of the mixer is 10 rpm, and the mixture (2) is obtained

[0037] 4) Add microcrystalline cellulose to the mixture (2) obtained in step 3, mix for 15 minutes, and the speed of the mixer is 10 rpm to obtain the mixture (3)

[0038] 5) Add magnesium stearate and sodium dodecylsulfonate to the mixture (3) obtained in step 4, mix for 10 minutes, and the speed of the mixer is 10 rpm to obtain the mixture (4)

[0039] 6) Take the mixture (4) obtained in s...

Embodiment 2

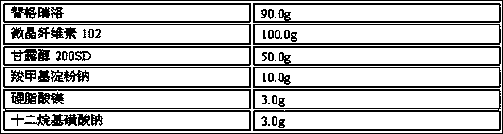

[0041] Ticagrelor dispersible tablets are prepared from the following components, according to the dosage of 1000 tablets

[0042]

[0043] Its preparation method comprises the following steps:

[0044] 1) Micronize ticagrelor to a particle size of <20µm;

[0045] 2) The croscarmellose sodium and mannitol were added twice in equal amounts, the mixing time was 10 minutes, the speed of the mixer was 10 rpm, and the mixture (1) was obtained;

[0046] 3) Add ticagrelor to the mixture (1) obtained in step 2, the mixing time is 15 minutes, the speed of the mixer is 10 rpm, and the mixture (2) is obtained;

[0047] 4) Add microcrystalline cellulose to the mixture (2) obtained in step 3, mix for 15 minutes, and the speed of the mixer is 10 rpm to obtain the mixture (3);

[0048] 5) Add magnesium stearate and sodium lauryl sulfonate to the mixture (3) obtained in step 4, mix for 10 minutes, and the speed of the mixer is 10 rpm to obtain the mixture (4);

[0049] 6) Take the mixtu...

Embodiment 3

[0050] Example 3 Ticagrelor dispersible tablets are formulated from the following components, in the amount of 1000 tablets

[0051]

[0052] Its preparation method comprises the following steps:

[0053]1) Micronize ticagrelor to a particle size of <20µm;

[0054] 2) The sodium carboxymethyl starch and mannitol were added twice in equal amounts, the mixing time was 10 minutes, and the speed of the mixer was 10 rpm to obtain the mixture (1);

[0055] 3) Add ticagrelor to the mixture (1) obtained in step 2, the mixing time is 15 minutes, the speed of the mixer is 10 rpm, and the mixture (2) is obtained;

[0056] 4) Add microcrystalline cellulose to the mixture (2) obtained in step 3, mix for 15 minutes, and the speed of the mixer is 10 rpm to obtain the mixture (3);

[0057] 5) Add magnesium stearate and sodium lauryl sulfonate to the mixture (3) obtained in step 4, mix for 10 minutes, and the speed of the mixer is 10 rpm to obtain the mixture (4);

[0058] 6) Take the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com