On-line short-circuit detection battery cell production and winding machine

A technology of short-circuit detection and integrated machine, which is applied in the directions of measuring electricity, measuring electric variables, and assembling battery machines, etc., which can solve problems such as long processing time, difficulty in ensuring accuracy, and complicated battery manufacturing process, so as to improve detection efficiency and save detection The effect of long time and round-trip distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

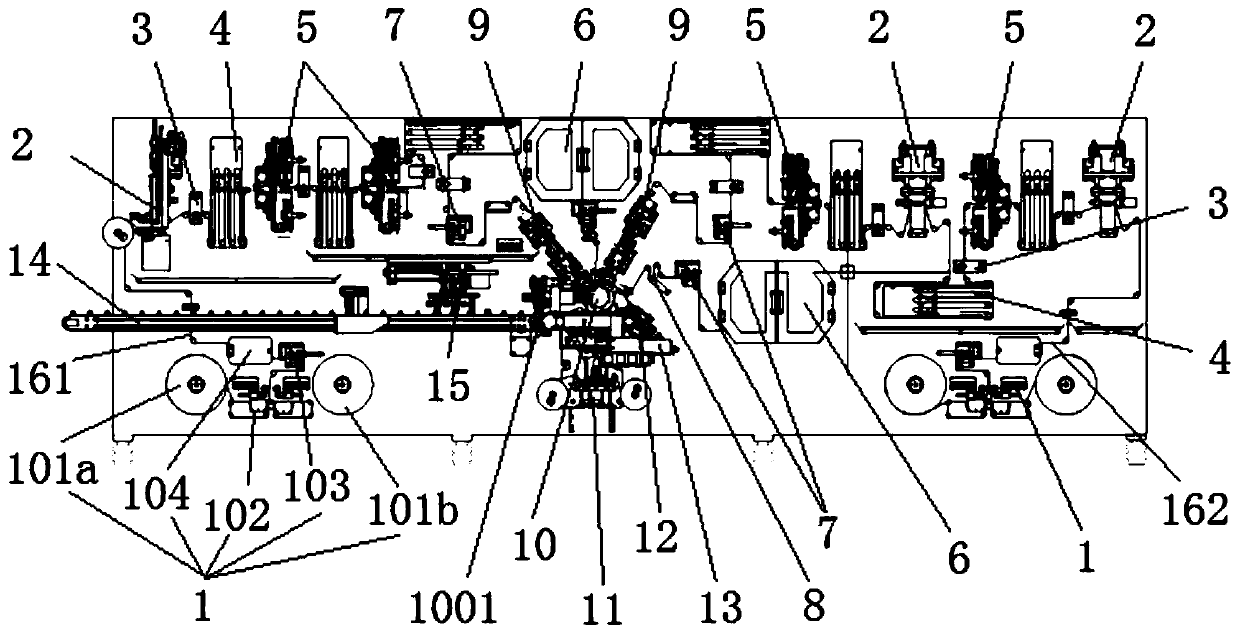

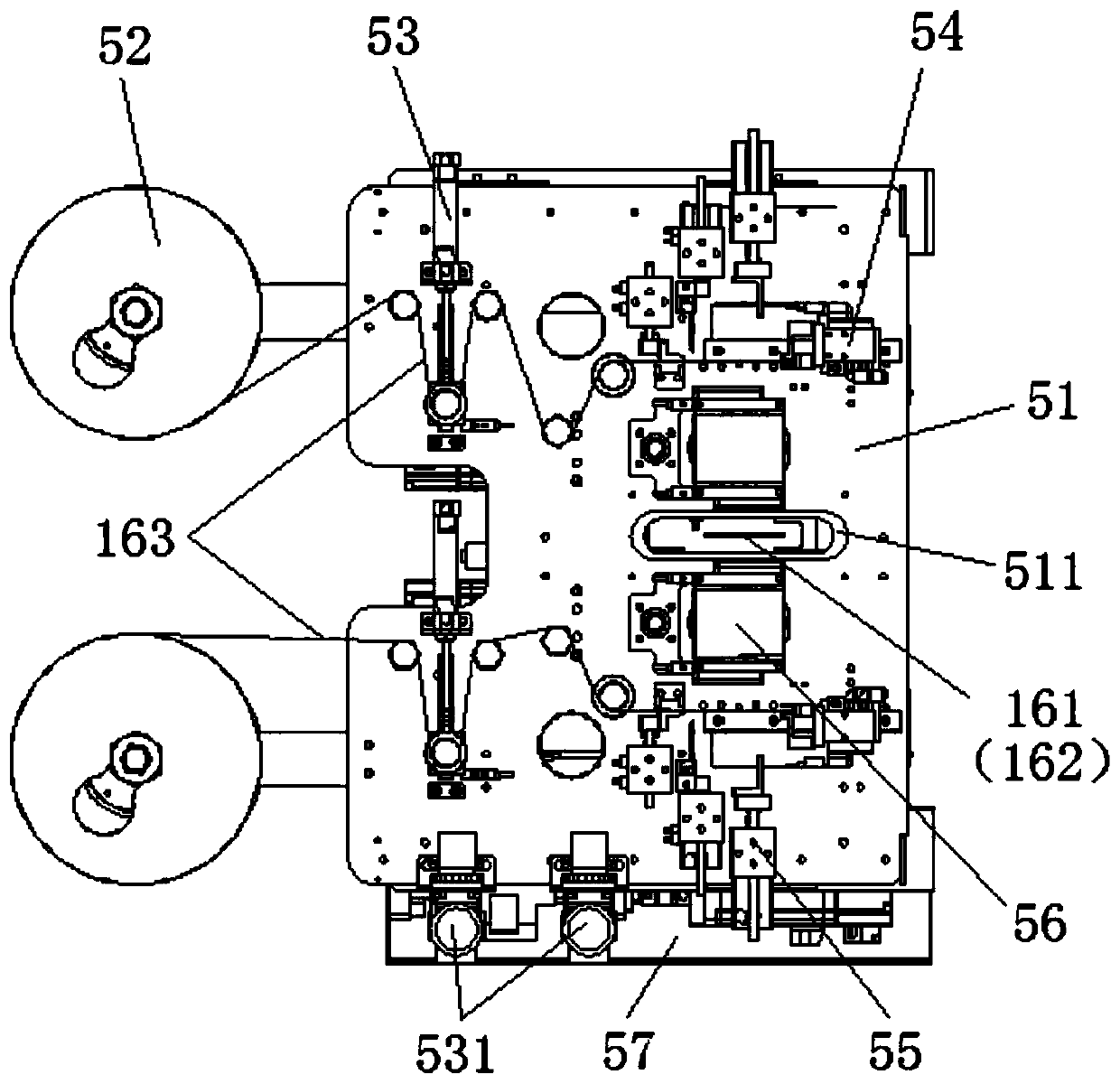

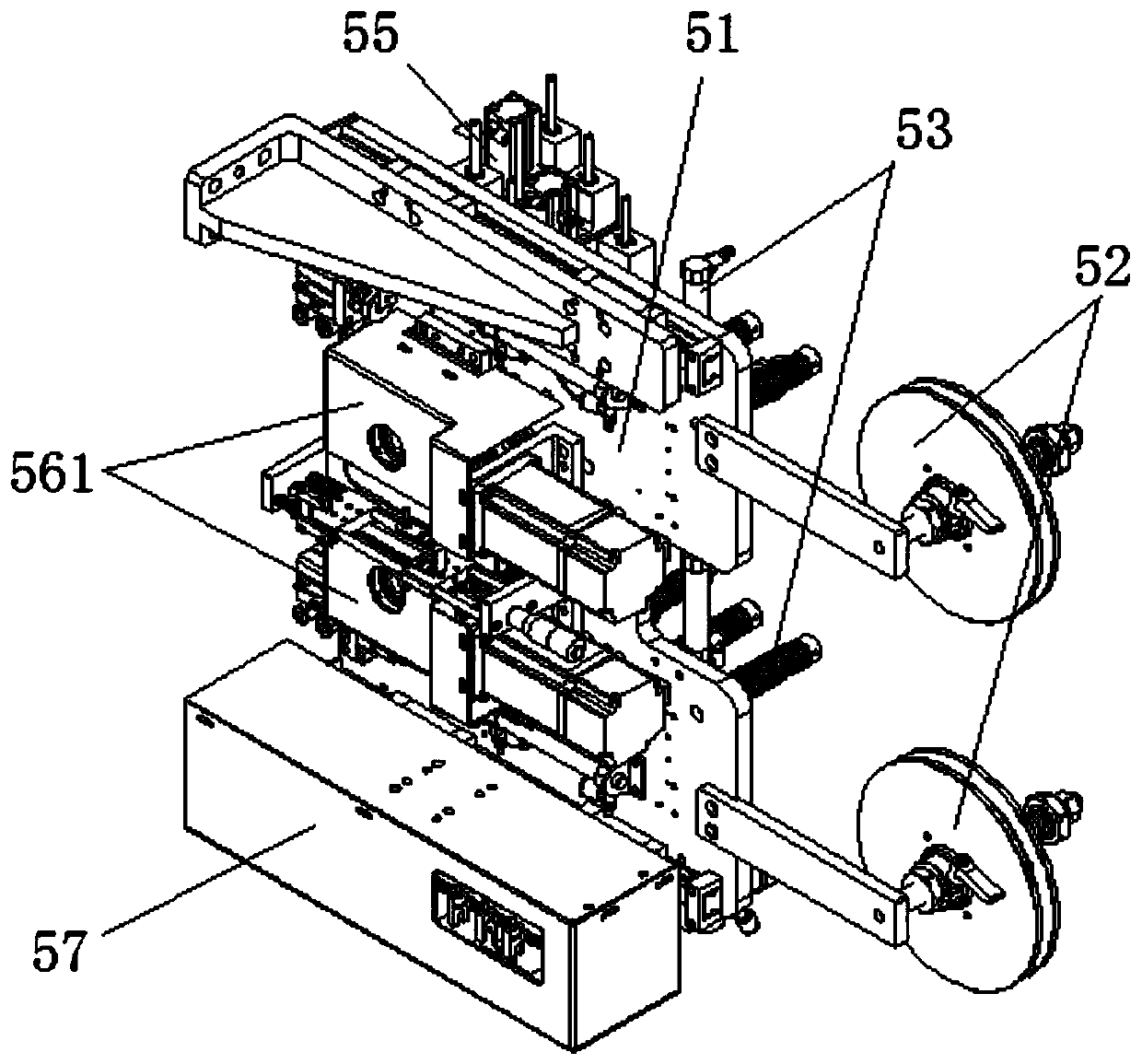

[0134] Such as figure 1 As shown, a cell manufacturing and winding integrated machine of the present invention includes a body and a positive electrode sheet processing part, a negative electrode sheet processing part, two sets of diaphragm processing parts, a winding part, a feeding manipulator 12, The ironing mechanism 13 and the cell conveying mechanism 14, the positive electrode sheet processing part includes the electrode sheet unwinding mechanism 1, the tab welding mechanism 2, the two tab protective glue mechanisms 5, the tension control device 7 and the sheet feeding mechanism arranged in sequence. Cutting mechanism 9; the negative plate processing part includes a pole piece unwinding mechanism 1, a tab welding mechanism 2, a tab protective glue mechanism 5, a tab welding mechanism 2, a tab protective glue mechanism 5, and a tension The control device 7 and the sheet feeding and cutting mechanism 9; the diaphragm processing part includes a diaphragm unwinding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com