A low-cost and highly active three-metal nanocomposite electrode preparation method

A nano-composite material and composite material technology are applied in the field of electrode preparation of highly active three-metal nano-composite materials, which can solve the problems of low utilization rate of metals, and achieve the effects of low price, low peak potential, and easy trace control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

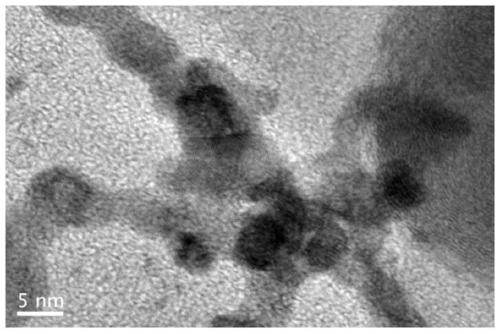

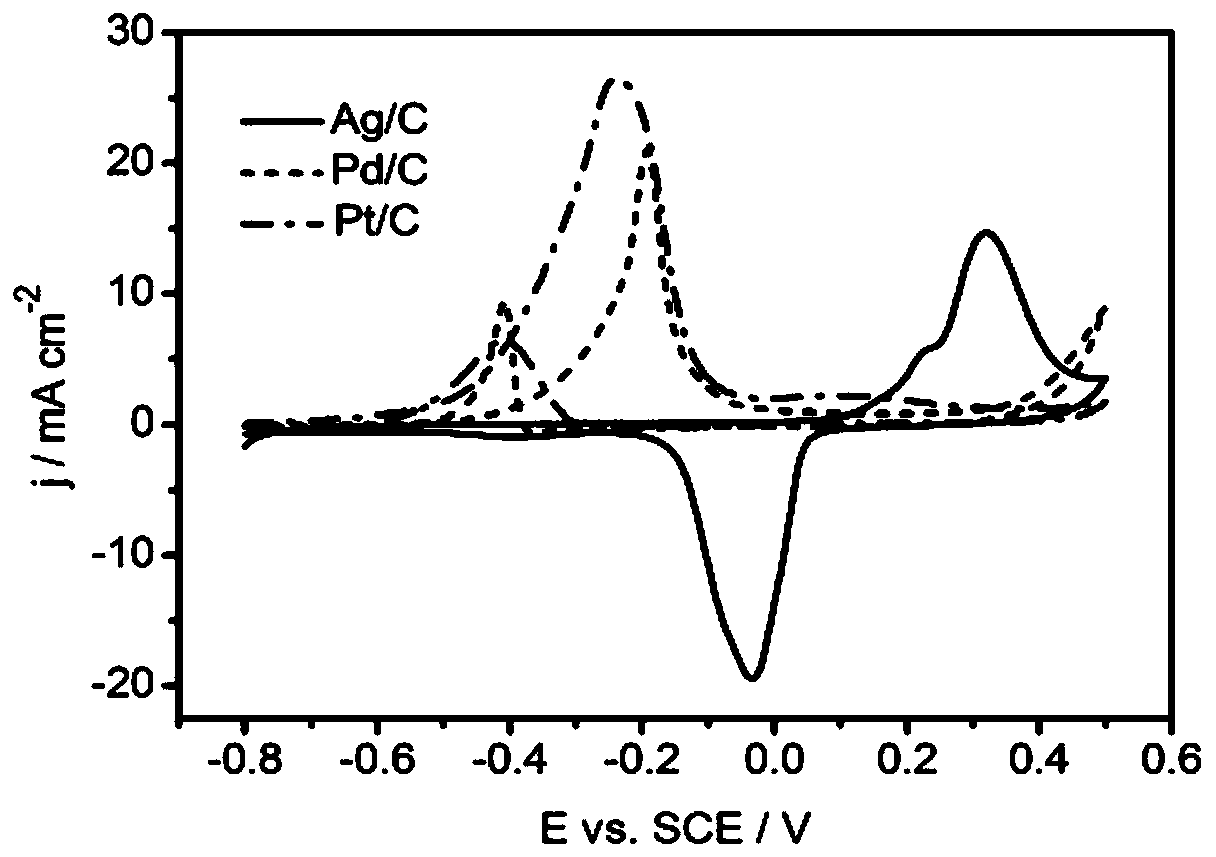

[0024] (1)Pt 1 Ag 2 / Carbon black electrode preparation. Take 1.7 mg of carbon black into 18 mL of double distilled water, and perform ultrasonic vibration on it for 40 minutes to obtain a carbon black suspension. Then add 2mL containing 0.8mM H 2 PtCl 6 , A drop of ammonia and 1.7mM AgNO 3 The mixed solution, continue ultrasonic vibration for 20 minutes to obtain 20mL containing AgNO 3 And H 2 PtCl 6 And a suspension of carbon black. Add 1mL 0.1M NaBH to the above suspension under magnetic stirring 4 Solution, continue to stir for 40 minutes, and then transfer the sample to a test tube and let it settle for 10 hours. After stratification, remove the supernatant, and then add 10μL of Nafion with a mass fraction of 5%, and ultrasonically treat for 5 minutes to obtain 0.5mL of black ink-like Pt 1 Ag 2 / Carbon black suspension. Then pipette 5μL of the above Pt 1 Ag 2 / Carbon black suspension is coated on the surface of a glassy carbon electrode with a diameter of 4mm and dried ...

Embodiment 2

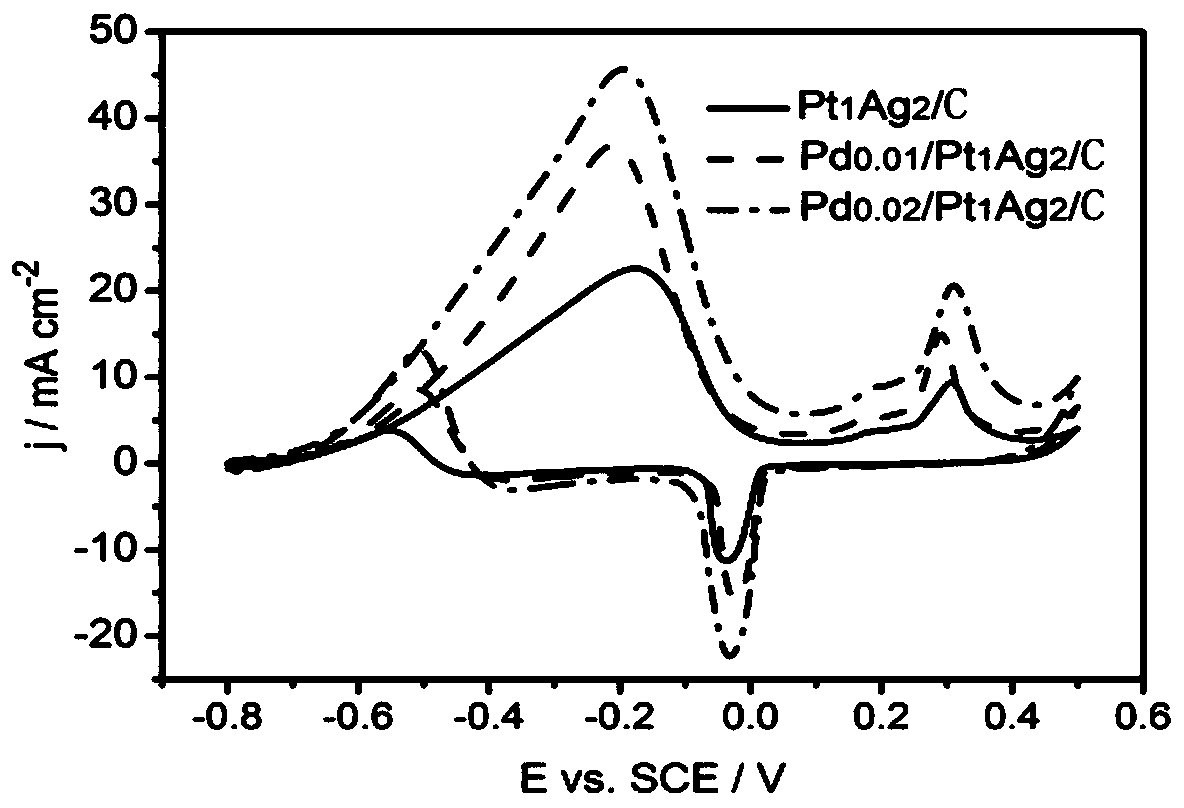

[0028] On the basis of Example 1, prepare Pd 0.01 / Pt 1 Ag 2 / Carbon black electrode.

[0029] (1)Pt 1 Ag 2 / Carbon black electrode preparation. The steps are the same as in Example 1 (1);

[0030] (2) Pd modified Pt 1 Ag 2 / Carbon black electrode. The procedure is the same as in Example 1 (2), but the Pd deposition time is 1 second. According to the charge amount during the deposition process, the Pd deposition amount is calculated to be about 0.13μg·cm -2 , Pd 0.01 / Pt 1 Ag 2 / Carbon black electrode.

[0031] (3)Pd 0.01 / Pt 1 Ag 2 / Carbon black electrode catalytic activity for the oxidation of ethylene glycol in alkaline medium. The steps are the same as in Example 1 (3), but the working electrode is Pd 0.01 / Pt 1 Ag 2 / Carbon black electrode, the result is as figure 2 Shown. Pd 0.01 / Pt 1 Ag 2 / The peak potential of the ethylene glycol oxidation reaction on the carbon black electrode is -0.21V, and the peak current density is 36.8mA·cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com