Preparation method of highly active electrode by one-step modification of ordinary metal nanocomposite surface with two noble metals

A nanocomposite material and ordinary metal technology, applied in the field of Au-Pt one-step modified Ni/graphene electrode, can solve the problem of low electrocatalytic activity, achieve high catalytic activity, short deposition modification time, and peak current density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Ni / graphene electrode preparation

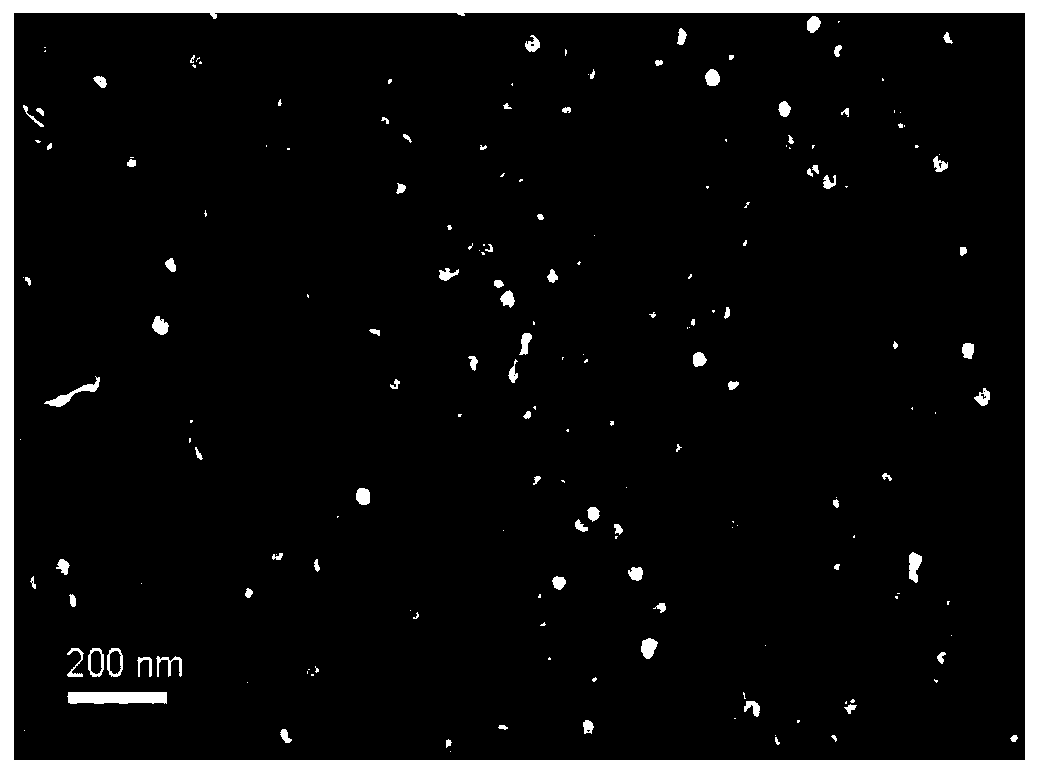

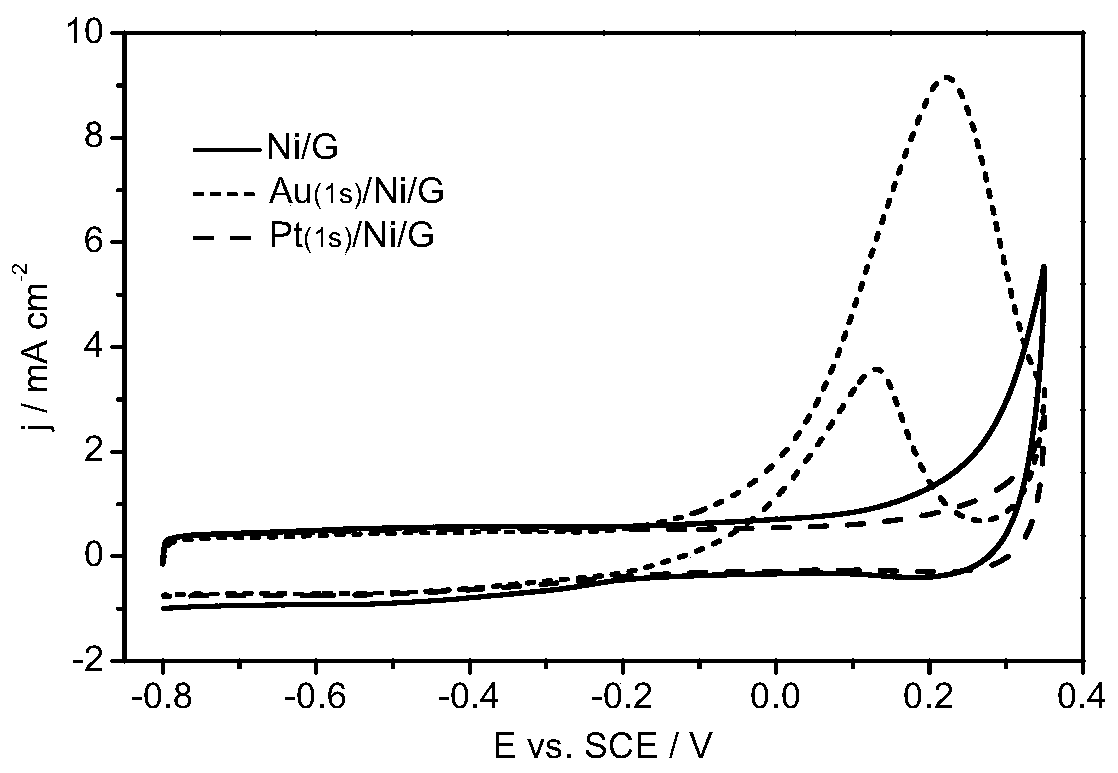

[0027] Using the Hummers chemical oxidation method, graphite flakes were prepared into graphite oxide, then 2 mg of graphite oxide was placed in 20 mL of double distilled water, and it was subjected to ultrasonic vibration for 40 min to obtain a brown transparent graphene oxide solution, and then 85 μL of 0.1M Ni (NO 3 ) 2 , and continued ultrasonic oscillation for 20 minutes to obtain about 20mL containing Ni(NO 3 ) 2 and graphene oxide solution; add 40mg NaBH to the above liquid under magnetic stirring 4 , continue to stir for 1.5h, then transfer the sample to a test tube and let it settle for 10h. After the layers were separated, the supernatant was removed, and the residual liquid was ultrasonically treated for 5 min. The resulting 1 mL black ink liquid was a Ni / graphene suspension. Successively use 0.3μm and 0.05μm Al 2 o 3 The surface of the glassy carbon electrode with a diameter of 4 mm is polished by polishing powd...

Embodiment 2

[0033] On the basis of Example 1, prepare AuPt (2s) / Ni / graphene electrode.

[0034] (1) Ni / graphene electrode preparation. Same as step (1) in Example 1.

[0035] (2) Au-Pt one-step modified Ni / graphene electrode. Ni / graphene electrode is as working electrode, and Au-Pt deposition time is 2s, and other conditions are identical with step (2) in embodiment 1, prepares AuPt (2s) / Ni / graphene electrode. The amount of Au-Pt deposited according to the amount of charge in the deposition process is about 0.70 μg / cm 2 .

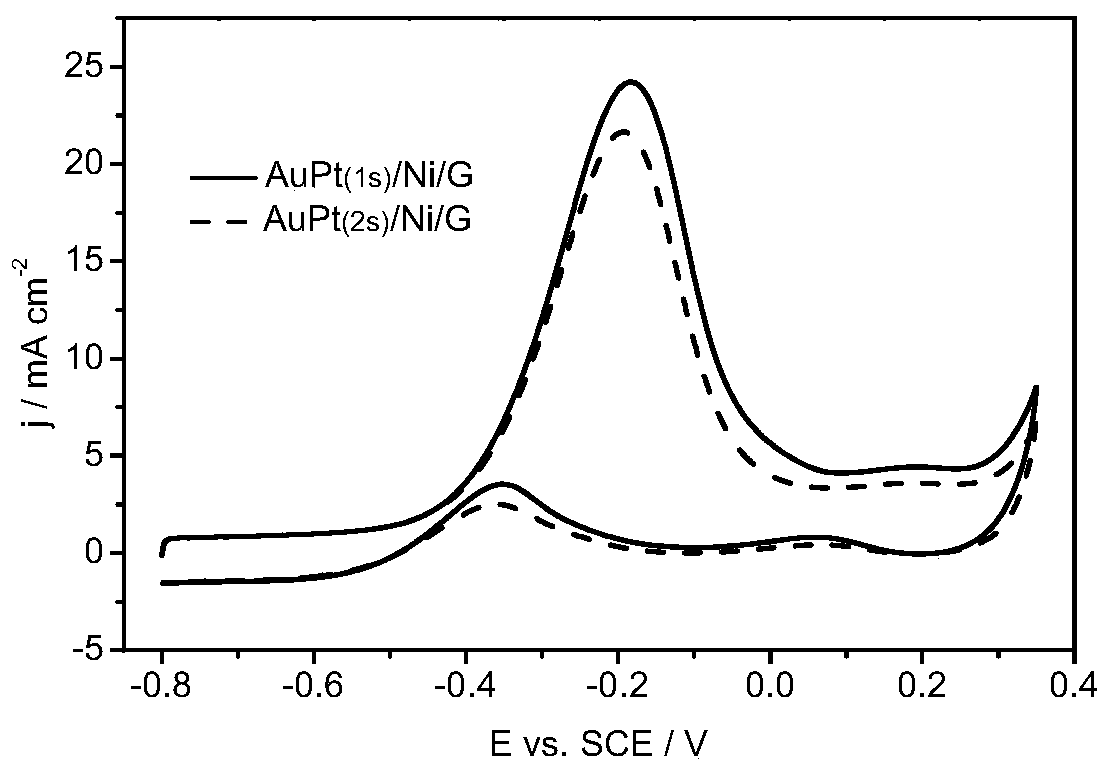

[0036] (3) AuPt (2s) Catalytic activity of / Ni / graphene electrode for ethylene glycol oxidation in alkaline media. Working electrode is AuPt (2s) / Ni / graphene electrode, other conditions are identical with step (3) in embodiment 1, and result is as follows figure 2 shown. AuPt (2s) The peak potential of the ethylene glycol oxidation reaction on the / Ni / graphene electrode is -0.19V, and the peak current density is 21.7mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com