Construction Method of Long-span Downward Rigid Tied Steel Arch Bridge

A construction method and technology for steel arch bridges, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long construction period, complicated procedures, heavy welding workload, etc., simplify the transportation environment and equipment requirements, and speed up construction The effect of progress and workload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

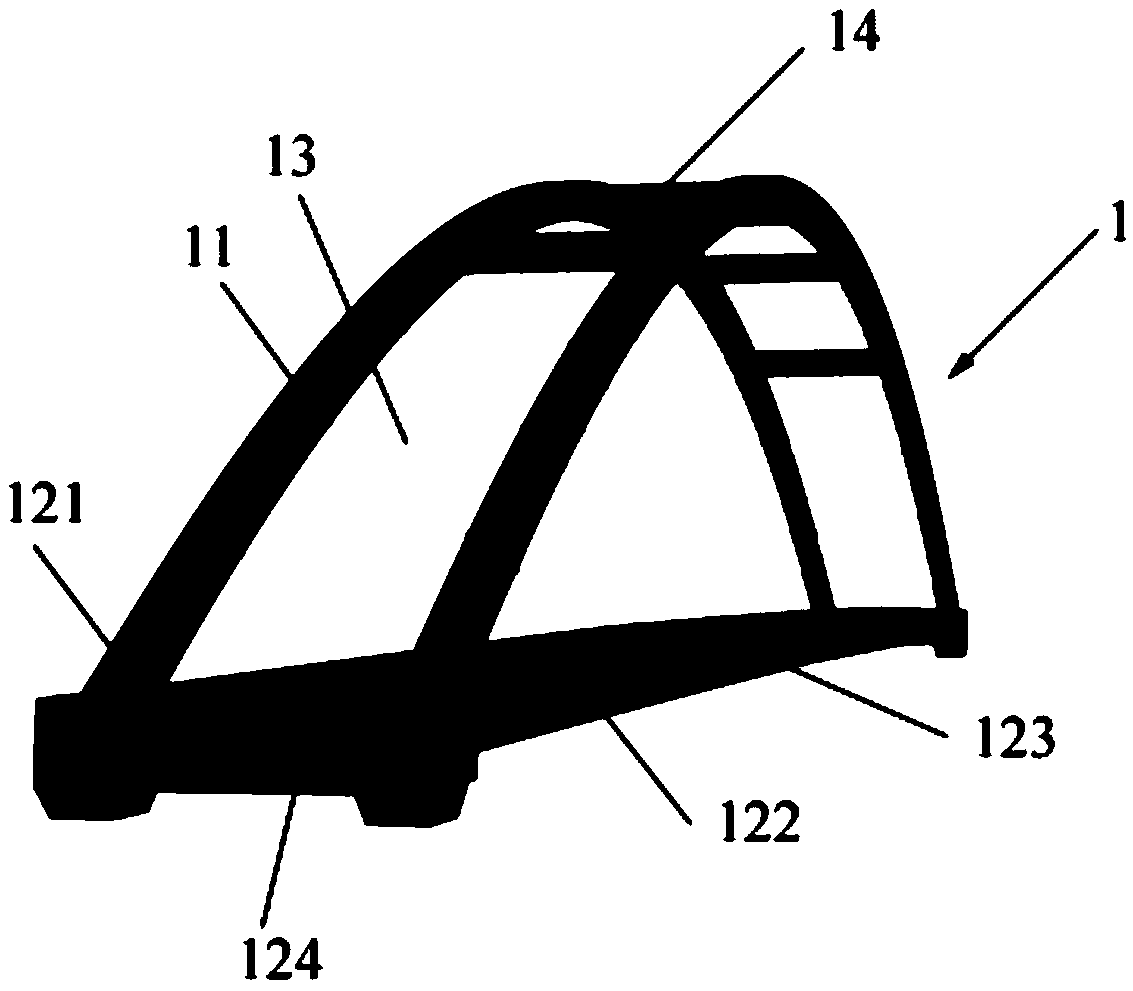

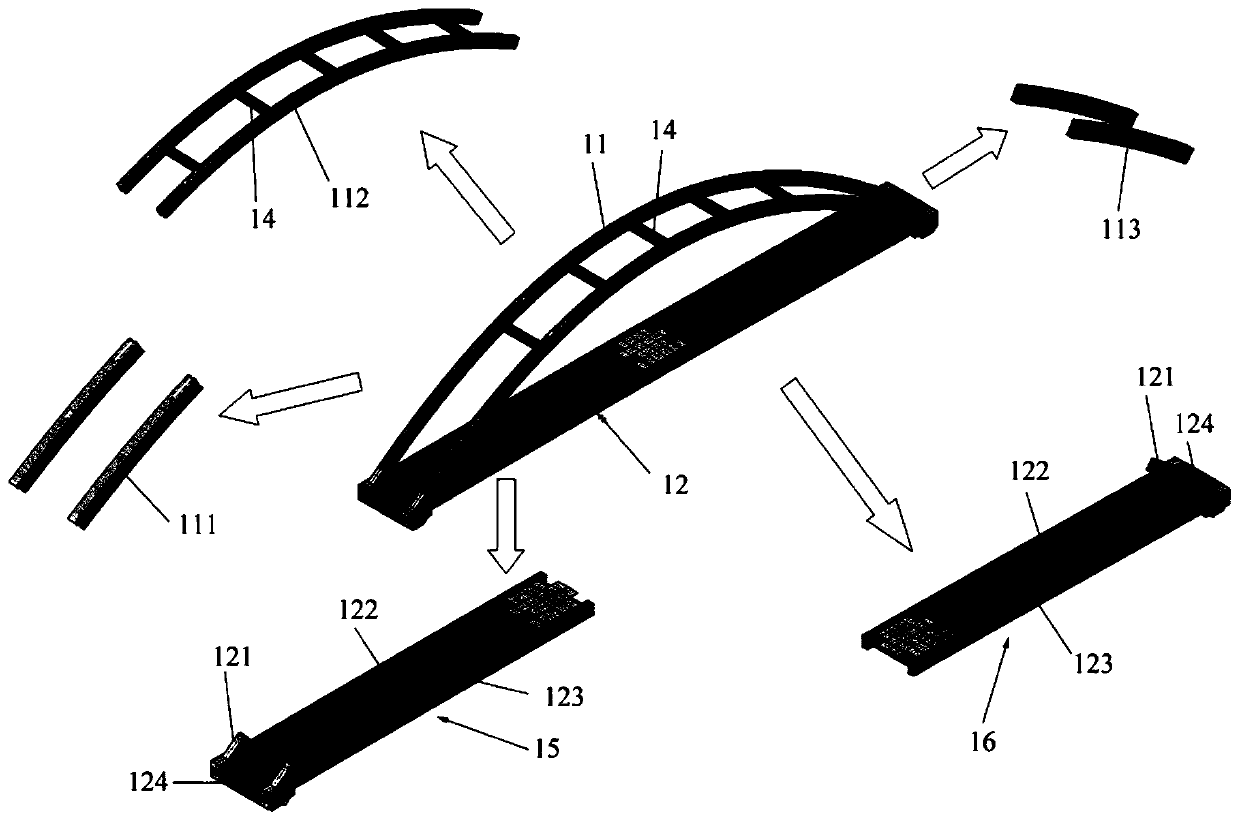

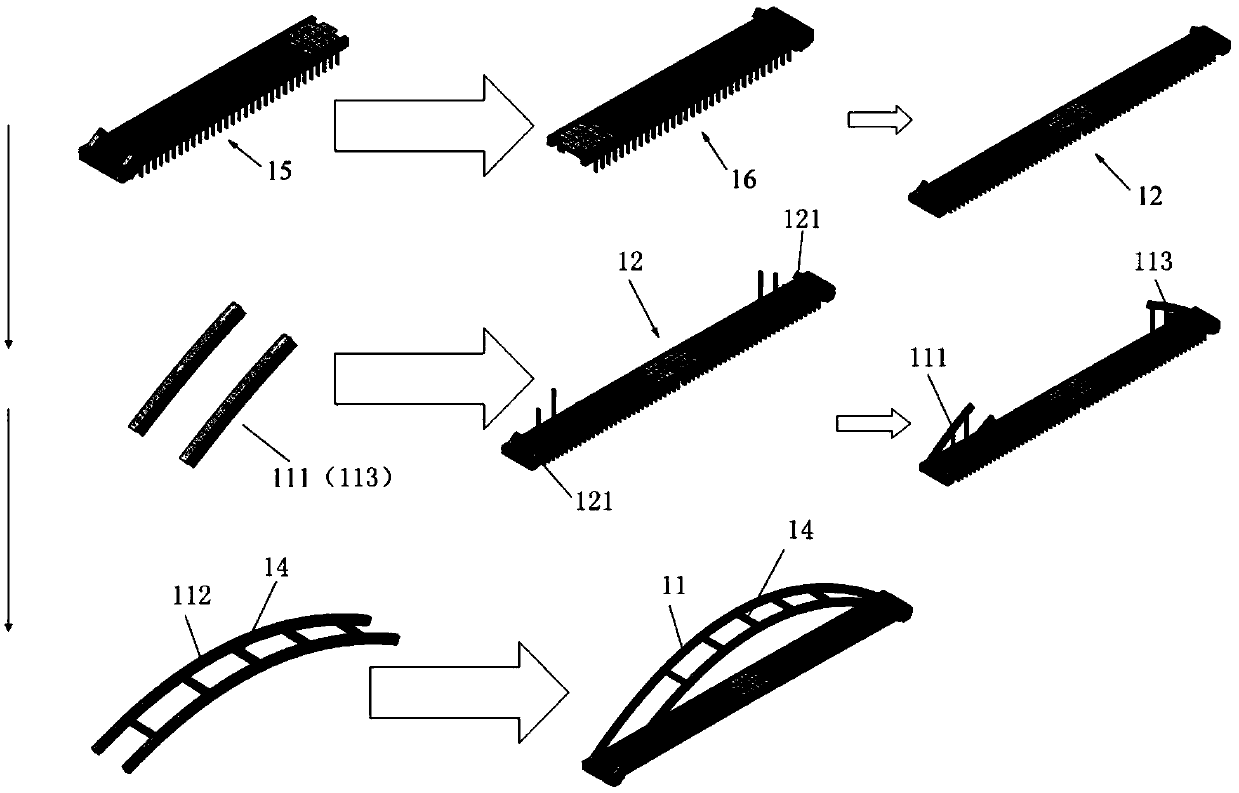

[0063] Such as Figure 13 and Figure 14 As shown, the steel arch bridge in the present invention comprises a bridge superstructure 1, a bridge substructure 2 and a bridge support 3 located between the bridge superstructure 1 and the bridge substructure 2, and the bridge superstructure 1 is a down-loaded rigid tie rod arch , the bridge substructure 2 is located on both banks of the narrow channel 4 , and the bridge superstructure 1 is erected on the narrow channel 4 .

[0064] The construction method includes the following steps:

[0065] Step 1: Complete the construction of the bridge substructure 2 at the bridge site. The bridge substructure 2 includes pile foundations 22 and bridge piers 21. During construction, constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com