Spherical grid structure capable of being rapidly installed

A grid structure and fast technology, applied in building construction, building material processing, construction, etc., can solve problems such as difficult high-altitude operations, heavy grid structure welding workload, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following describes the spherical grid structure of the present invention in conjunction with the installation process, and examples of the embodiments are shown in the accompanying drawings.

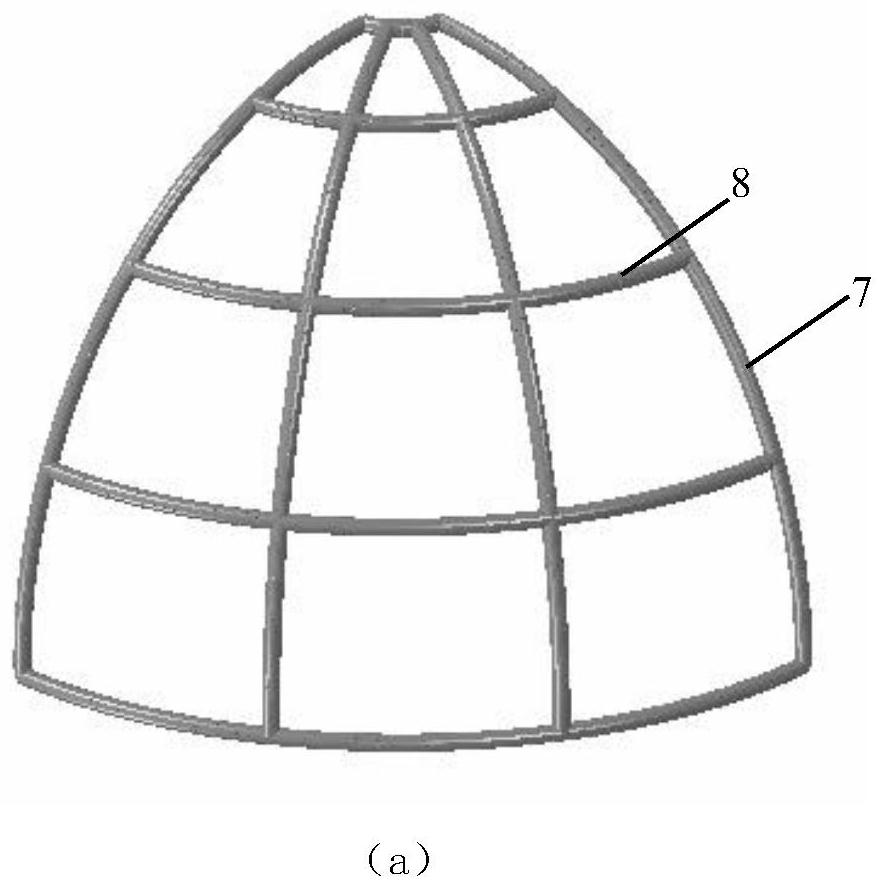

[0031] In this embodiment, the grid structure (4) is a quarter complete spherical grid structure, and the grid structure (4) is a spherical grid structure, which is suitable for medium and small spans, and the grid structure (4) The ring rod (7) and the radial rib (8) are connected and assembled on the ground to reduce high-altitude operations and ensure the quality of the forming. The two fulcrums of the assembled grid structure (4) are hinged to the ground with pin bearings (5). The purpose of this treatment is to allow the grid to rotate. The steel column (1) is hinged to the ground and can rotate together with the grid structure. The quick-installation device of the grid structure (4) is as follows: figure 1 shown.

[0032] The whole construction process of embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com