Concrete pouring method for reinforced concrete lattice beams in slope treatment

A lattice beam and concrete technology, applied in excavation, construction, infrastructure engineering and other directions, can solve the problems of manpower and material resources, low efficiency, and difficult construction, and achieve low construction cost, low condition requirements, and high construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with accompanying drawing:

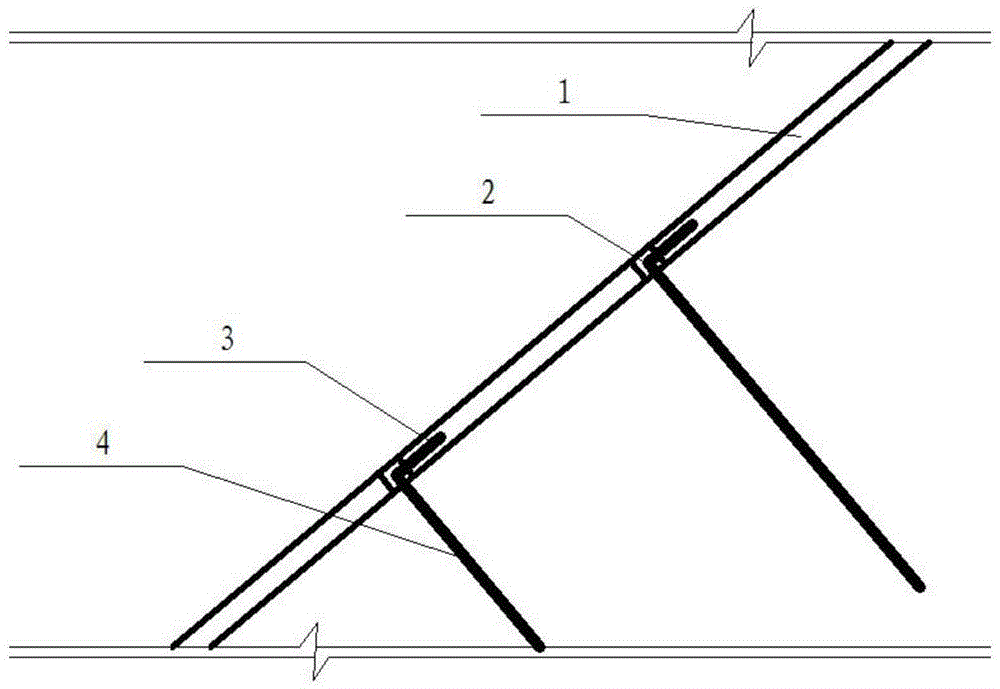

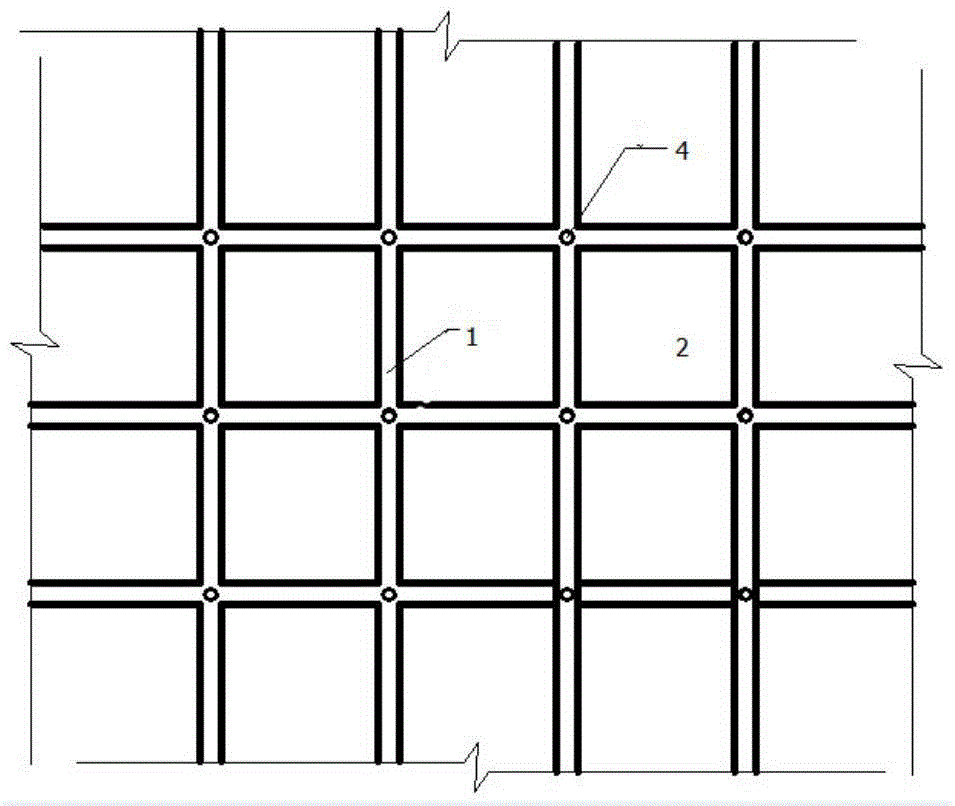

[0015] Such as figure 1 , figure 2 As shown, the sprayed reinforced concrete lattice beams in slope treatment mainly include longitudinal lattice beams 1, transverse lattice beams 2, anchor rods anchored into lattice beams 3, and anchor rods 4

[0016] The specific implementation steps are as follows:

[0017] a. Leveling of the side slope: According to the design requirements, level the slope surface that needs to be treated;

[0018] b. Construction of lattice beam anchors: the construction of anchors can be done manually or mechanically. After the anchors are implanted and grouted, the anchors need to be anchored into the transverse lattice beams (2) and longitudinal lattice beams (1) );

[0019] c. Lattice beam construction: Bind the steel bars of the transverse lattice beam (2) and the longitudinal lattice beam (1) according to the design requirements, and suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com