Crystal silicon polishing additive and use method thereof for crystal silicon polishing

A technology of crystalline silicon and additives, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of poor control of the reaction process, high cost of polishing liquid, environmental pollution, etc., and achieve great practical value, Promote polishing effect and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

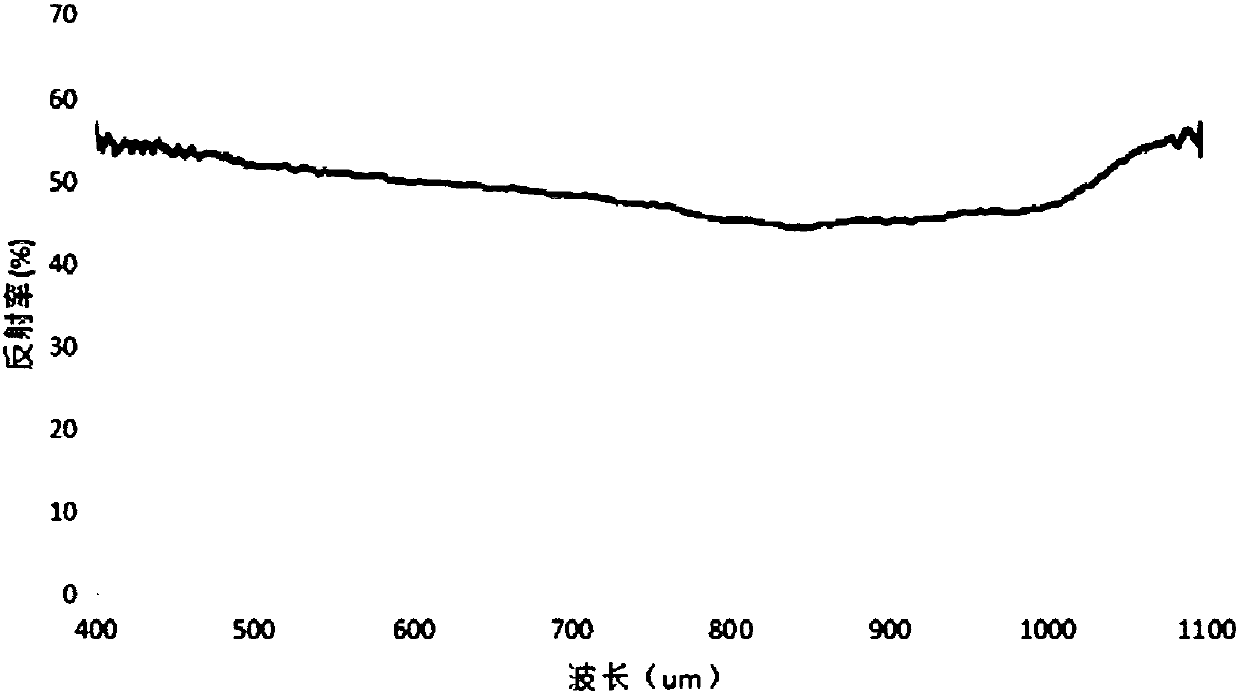

Image

Examples

Embodiment 1

[0020] To prepare a crystalline silicon polishing additive, mix and dissolve 10 g of sodium citrate, 10 g of palmitic acid, 2 g of cetyltrimethylamine oxide, and 1.5 ml of Tween into 1 L of deionized water to obtain a crystalline silicon polishing additive. Add 5000g of sodium hydroxide and 1L of amorphous silicon polishing additive into 160L of deionized water to obtain a polishing solution. The polishing solution was heated up to 65°C, and then the diffused PSG-removed silicon wafer was immersed in the polishing solution for polishing. The polishing time was 200s. The obtained silicon wafer was detected by scanning electron microscopy with a lattice base size of 10-30 μm and no other shapes. appearance impurities.

Embodiment 2

[0022] To prepare a crystalline silicon polishing additive, mix and dissolve 15 g of sodium citrate, 15 g of palmitic acid, 3 g of cetyltrimethylamine oxide, and 2.25 ml of Tween into 1.5 L of deionized water to obtain a crystalline silicon polishing additive. Add 4000g of sodium hydroxide and 1.5L of crystalline silicon polishing additive into 180L of deionized water to obtain a polishing solution. The polishing solution was heated up to 75°C, and then the diffused PSG-removed silicon wafer was immersed in the polishing solution and polished for 120s. The obtained silicon wafer was detected by a scanning electron microscope with a lattice base size of 10-30 μm and no other shapes. appearance impurities.

Embodiment 3

[0024] On the basis of embodiment 1, change sodium hydroxide to be 3000g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com