Flame-retarding ABS/POK alloy and its preparation method

A technology of ABS resin and alloy, which is applied in the field of flame-retardant ABS/POK alloy and its preparation, can solve the problems that ABS cannot meet the actual needs, the mechanical properties of materials decrease, and the alloy processing temperature is high, so as to facilitate industrialized large-scale production and good mechanics Excellent performance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of above-mentioned flame-retardant ABS / POK alloy comprises the following steps:

[0053] 1) Dry the raw materials first, and then add each raw material into the mixer to fully stir and mix evenly;

[0054] 2) Transfer the raw materials in the mixer to a twin-screw extruder, extrude, cool, granulate, and dry to obtain a flame-retardant ABS / POK alloy.

[0055] Preferably, the drying described in step 1) is carried out at 80-100° C., and the drying time is 1-2 hours.

[0056] Preferably, the rotation speed of the stirrer in step 1) is 400-800 r / min, and the stirring time is 6-10 min.

[0057] Preferably, in step 2), the temperature of each temperature zone of the twin-screw extruder is 150-230° C., the feeding speed is 12-24 r / min, and the main engine speed is 220-600 r / min.

Embodiment

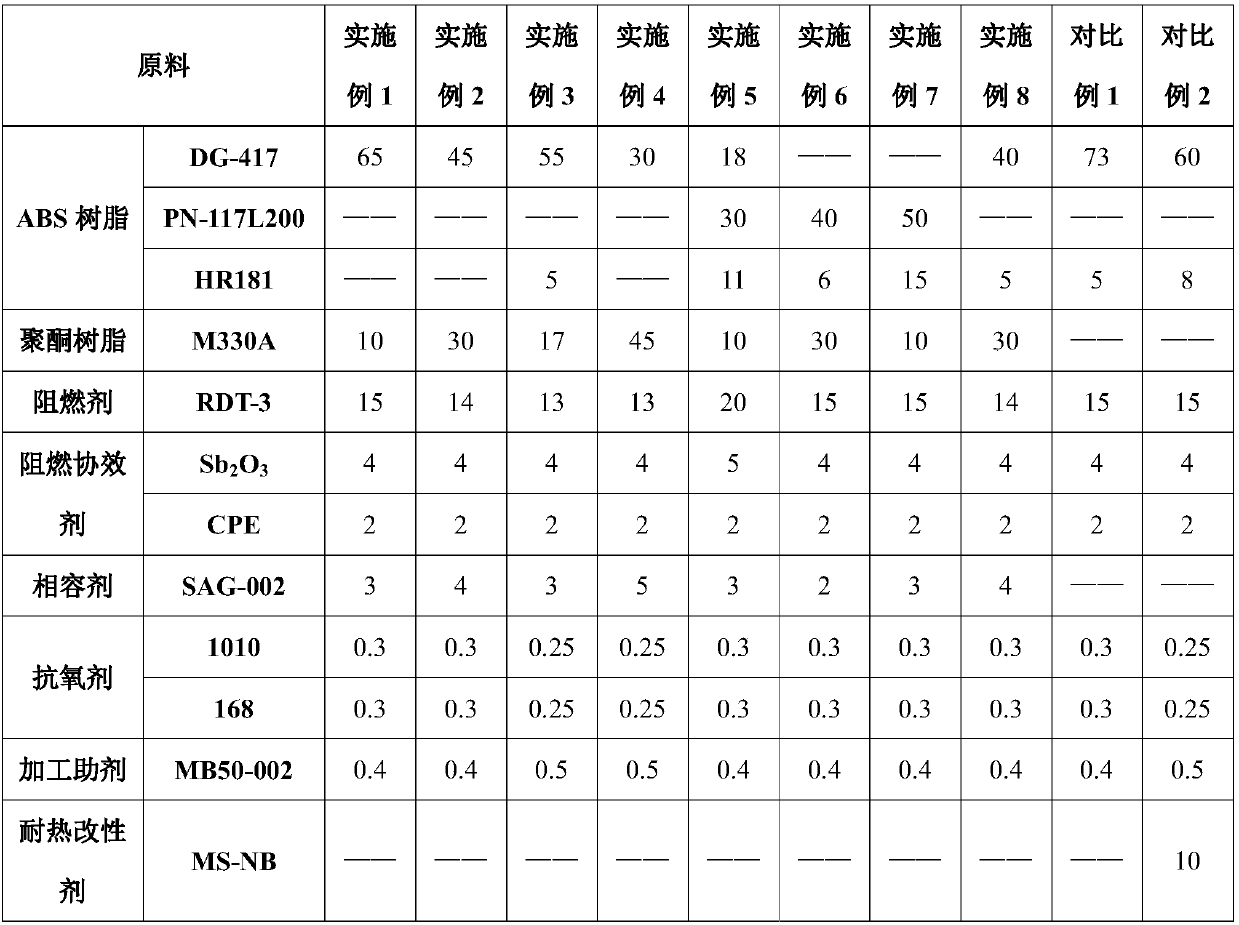

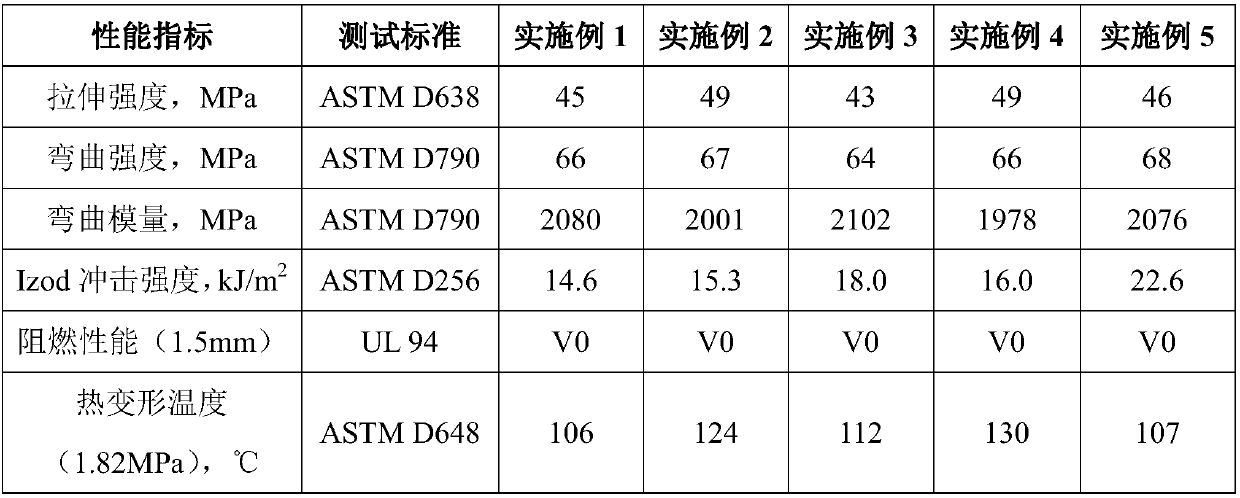

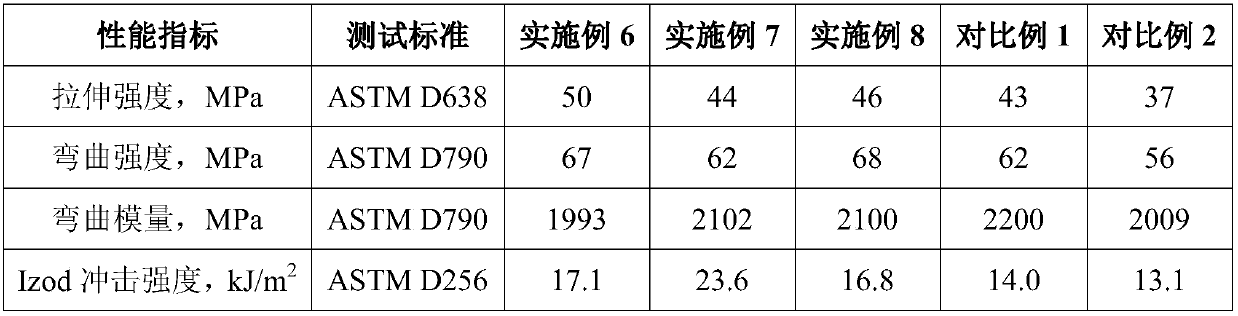

[0060] The raw material composition of the flame-retardant ABS / POK alloy of Examples 1-8 and the heat-resistant flame-retardant ABS of Comparative Examples 1-2 is shown in the following table (parts by mass):

[0061] Table 1 The raw material composition table of the flame-retardant ABS / POK alloy of Examples 1-8 and the heat-resistant flame-retardant ABS of Comparative Examples 1-2

[0062]

[0063] Dry the above-prepared raw materials at 85°C for 2 hours, and then put them into a high-speed mixer and stir for 10 minutes at a speed of 600 rpm. Put the mixed raw materials into the twin-screw extruder to extrude, cool, granulate and dry. The 11 temperature zones of the twin-screw extruder are respectively set to 150°C, 190°C, 220°C, 220°C, 220°C, 220°C, 215°C, 215°C, 215°C, 215°C, and 220°C. The feeding speed is 15 rpm, and the host speed is 350 rpm.

[0064] Note:

[0065] ABS: DG-417, Tianjin Dagu Chemical Co., Ltd.;

[0066] AS: PN-117L200, Taiwan Chi Mei Industrial Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com